Fatigue damage of components is cumulative, with cracks propagating until the component is unable to withstand the application of a single load, which results in failure. Fatigue life is affected by factors such as mean tensile stress, stress amplitude, fatigue strength of the material and residual tensile stresses from the manufacturing process.

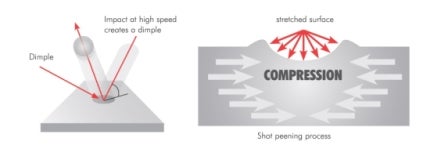

Tensile stresses attempt to pull or tear the material apart, accelerating crack propagation. A proven cost-effective technique to extend the fatigue life of equipment is to carry out a controlled shot peening operation. This involves firing spherical media (shot) at the surface of a component in a highly controlled manner. As the shot hits the surface it produces a dimple causing elastic plastic deformation. These dimples overlap during the process, replacing harmful tensile stresses with a layer of compressive residual stress. This layer is very effective at preventing the initiation and propagation of fatigue cracks by effectively reducing the applied load at the surface and sub-surface.

Other failure problems, such as stress corrosion cracking and corrosion cracking, can also be successfully addressed by the application of controlled shot peening. Typical applications include oilfield drilling equipment, welded structures and pumps and valves.

Laser peening is a highly controlled process that allows precise, surgically accurate peening with results five to ten times deeper than controlled shot peening with considerably less cold working.