Curtiss-Wright Surface Technologies (CWST) offers a wide range of services to combat corrosion fatigue, including controlled shot and laser peening, thermal spray, engineered coatings and analytical services, delivered worldwide to extend the life of critical components.

Typical applications are turbines, pumps, compressors and steel tubing systems, as well as welded structures and assemblies, reducing maintenance and whole life costs by extending the life of the plant and equipment.

Corrosion fatigue, stress corrosion cracking, fretting, spalling and wear in the oil and gas industry account for more service and maintenance stoppages than any other issues relating to engineered components, especially where components are operating in harsh environments.

Our industry approvals include AS9100 Rev C, NADCAP, ISO 9001:2008 and key customer approvals as necessary.

Controlled shot and laser shock peening

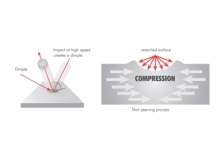

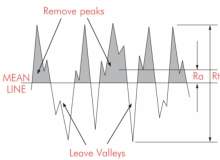

A recognised and trusted process extensively used in the aerospace and automotive industry, controlled shot peening can address the premature failure of components by inducing a beneficial compressive stress into the surface and sub-surface.

As well as in-house operation, this process can be repeated for components on-site in order to address problems of repair, overhaul and maintenance. Controlled shot peening is also used to control stress corrosion cracking and corrosion fatigue in welded components and structures that are subject to high stress intensities.

Laser shock peening is a precision process used to induce beneficial compressive stresses more than ten times that of controlled shot peening, with virtually no cold working of the surface.

Thermal spray coatings for corrosion resistance

Our thermal spray coatings provide thermal protection, abrasion resistance, high-temperature oxidation / corrosion resistance and solid particle erosion control. They can be used as a replacement for hard chrome plating and to repair worn components to bring them back to their original specifications.

Engineered coatings for harsh offshore conditions

CWST’s Everlube® coatings provide both dry film lubricant and corrosion protection against wear, corrosion, erosion, seizing, steam and extreme temperatures (-420°F to 1,800°F / -251°C to 982°C).

Our Everslik 1201/1301 system is typically used on pumps, valves, connectors, actuator systems, shafts, fasteners and jack screws. The system consists firstly of an extremely tough and durable coating primer, followed by a top coat of a high-loading MoS2-based coating with a proven salt spray resistance of 2,500h.

We are constantly improving to meet our customers’ needs, with our weight limit increasing to 7.5t and oven size to 4m². Our PROCOAT100™ provides proven protection against corrosion in the harshest operating environments.

Worldwide service and on-site work

CWST has more than 70 divisions worldwide, in Europe, Asia and North America, so we can offer our customers a local service, providing one-stop-shop capabilities and a single point of service for all their surface treatment needs.

We also have fully experienced teams with specialist portable equipment, ready to be mobilised at short notice to virtually any country to carry out on-site work to the same high standard as our in-house operations.

About Curtiss-Wright Surface Technologies

Surface Technologies is a division of Curtiss-Wright, a global innovative company that delivers highly engineered critical function products and services to the commercial, industrial, defence and energy markets.

Building on the heritage of Glenn Curtiss and the Wright brothers, The Curtiss-Wright Corporation has a long tradition of providing reliable solutions through trusted customer relationships. The company employs approximately 10,000 people worldwide.