Ithaca Energy is decommissioning the Anglia gas field infrastructure located in the Southern North Sea, approximately 55km away from the UK mainland.

The Anglia field infrastructure is co-owned by Ithaca Energy (44.64%), Dana Petroleum (37.2%) and Ineos UK SNS (18.15%).

The application for the cessation of production from the field was submitted to the Oil and Gas Authority (OGA) in November 2015 and was approved in May 2016.

The Offshore Petroleum Regulator for Environment & Decommissioning (OPRED) approved the decommissioning programme of the field in June 2020. The project has been outlined as a seven-year decommissioning plan to be implemented between 2020 and 2027.

Petrex Developments developed the plan to clean the pipeline system as the first phase of the subsea facilities decommissioning programme in April 2019.

Anglia gas field decommissioning project background

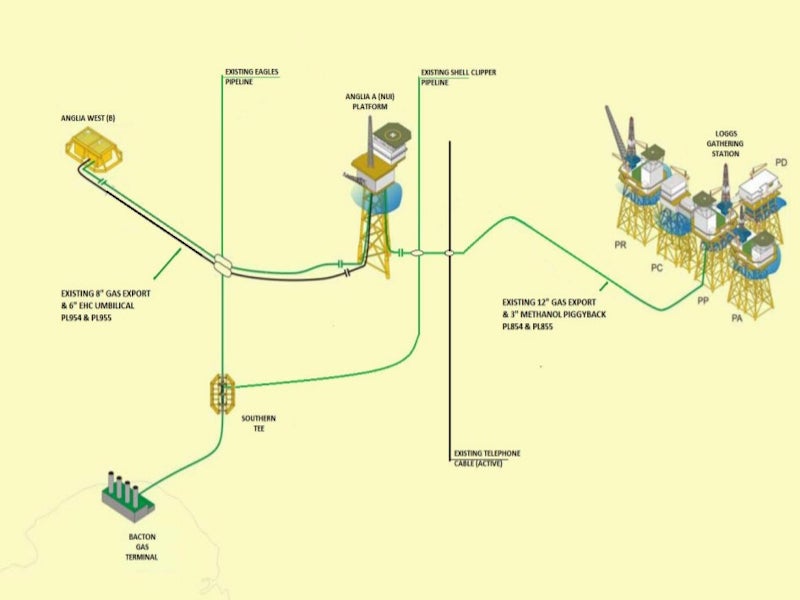

Discovered in 1972, the Anglia gas field lies in UK Blocks 48/18b and the export line traverses Blocks 48/19 and 48/20 at a water depth of approximately 27m. The decommissioning programme comprises the decommissioning of two field installations and four field pipelines.

The Anglia field was initially developed with a three-legged fixed normally unattended installation (NUI) platform named Anglia A, which supported six platform wells. The first production from the field started in 1991.

Two additional subsea wells, Anglia West (B) were added to the west of the Anglia A along with associated subsea equipment in 1993. The subsea production wells were tied back to the Anglia A platform via a 5km-long, 8in-diameter infield concrete-coated steel production pipeline at a water depth of 22.5m and 31m respectively.

The installations were used for the production and treatment of gas from the reservoir. The gas was transported to the Conoco Phillips’ Lincolnshire Offshore Gas Gathering System (LOGGS) facility via a 23.7km-long 12in-diameter steel production pipeline and then sent to the onshore Theddlethorpe Gas Terminal (TGT) for processing.

The topsides and jacket of the platform weigh approximately 870t and 1088t respectively, while the Anglia West (B) manifold weighs 110t. The subsea installations include manifold structures such as piles, protection frame, and control modules.

Details of facilities to be decommissioned

The facilities that will be decommissioned under the programme include Anglia A platform, Anglia West (B) manifold with the integrated protective structure, six production wells at Anglia A, two subsea production wells at Anglia West (B), and three subsea appraisal wells.

The pipeline system to be decommissioned includes the 5km-long Anglia pipeline system connecting Anglia A to Anglia West (B), the 5km-long 6in multicore flexible control umbilical, which are trenched and buried separately, and the 12in production pipeline between Anglia A and LOGGS PP platform along with 3in trenched and buried piggybacked methanol line connecting the Anglia A platform with LOGGS PP platform.

Other infrastructure to be removed includes protective material such as concrete mattresses, grout bags, frond mats and deposited rock.

Anglia field decommissioning programme

The topsides and jacket of the Anglia gas field platform will be completely removed for recycling. The topsides have been flushed to clean the hydrocarbons, while the legs will be cut below the cellar deck to lift the topsides from the jacket.

The piles will be cut 3m below the seafloor to remove the jacket by a single lift. The topsides and jacket will be transported onshore for recycling. The subsea manifold structures will be disconnected and completely removed by cutting the piles 3m below seabed for onshore transportation using either construction support vessel (CSV) or crane vessel.

The wells, including some previously suspended appraisal wells, will be plugged and abandoned using drill rig. Pipelines will be disconnected and the tie-in spools will be removed using support vessels. The control umbilical will be completely removed and the drill cuttings will be left in place to degrade naturally.