The Blane oilfield is located in block 30 / 3a and Norwegian block 1 / 2 in the southern part of the North Sea. Discovered in 1989, the field lies about 260km east of Aberdeen, UK, at a water depth of 230ft. An investment of £250m was made to develop the field.

The Blane field is operated by Talisman Energy, which has a 43% interest in the field. Eni UK and Eni ULX held 13.8% and 4.1% interests, respectively, in the field. Faroe Petroleum (Faroe) acquired an 18% stake from Eni UK and Eni ULX for £60m in May 2011.

The field will increase Faroe’s production by 1,900 barrels of oil equivalent per day. Other partners include Roc Oil with 12.5%, MOC Exploration with 14% and Dana Petroleum with 12.5%.

Blane field reserves and development

The Blane field is estimated to contain proven and probable reserves of 30.4 million barrels of oil equivalent (mboe). Nearly 97% of the field’s reserves are oil.

The Blane field development plan was submitted in May 2005 and was approved in July 2005. Because the field lies on the UK and Norwegian borders, it was unitised, with the UK holding 82% and Norway holding 18%. The Unitisation and Unit Operating Agreement was signed in July 2005.

Drilling of development wells started in May 2006. Two cased horizontal production wells A and B were drilled in October 2006. Tie-back of the wells to the Ula platform was completed in the second quarter of 2007. The wells feature 1,220m perforated segments to enable the intersection of multiple layers. They are equipped with gas lift facilities for production at high water cuts.

A third sub-vertical water injection well C was drilled by Ocean Princess rig in 2007. The well was tied back to the Ula platform in May 2008.

Geology of the Blane field

The Blane field reservoir is a four-way structural closure located at a depth of 9,800ft in Central Graben. Oil is formed in tertiary Palaeocene sandstone of the Forties Formation in an unconfined, sheet-like, turbidite fan structure. The reservoir is highly over-pressured and contains high quality oil with 42° API.

Ula platform

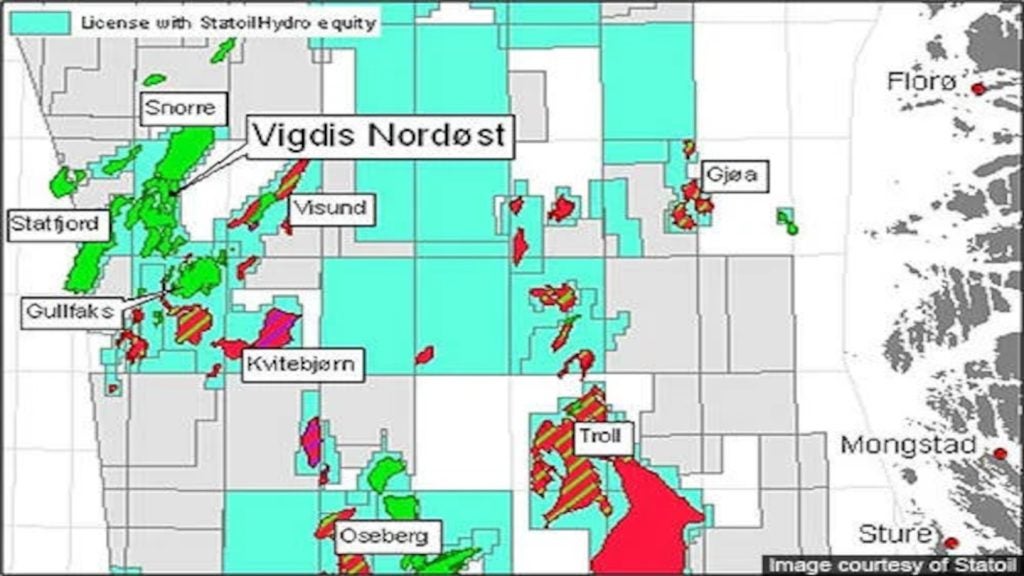

The Blane field’s production wells are tied-back to BP-operated Ula field platform located about 34km north-east of Norway on the UK Continental Shelf. The tie-back required topside modifications such as the installation of two pipelines – a 34km 10in pipeline for oil production and another 34km 6in pipeline for gas lift.

A 450mt module was also installed to process Blane’s production. The main components of the module include a separator and a Caisson equipped with risers. A staircase featuring a platform was included in the module for setting ESD valves. In addition, a new gas treatment and injection module was installed.

BP launched the Ula Gas Compression Upgrade project in 2007 to improve the gas handling capacity of the Ula platform.

The project doubled the gas handling capacity of the platform to 120Mcf per day. It supplied gas for gas lift of Blane’s production wells.

Production at Blane

First production from the Blane field began in September 2007. Gas lift from the two production wells was started in February 2009.

This was later discontinued due to several small subsea leakages in the pipeline in 2009. Repair of the pipeline was completed in August 2010.

From the Ula platform, oil is transported to the Teeside Oil Terminal through a subsea pipeline. The gas produced at the Blane field is used for injection into the Ula reservoir. Average production rate of the field in September 2010 was 11,964 barrels of oil per day. Production is expected to reach a peak rate of 17,000boe per day.

Ula processing systems

The well-stream is separated in a dedicated separator, which is equipped with individual metering packages for gas, oil and water production. After being separated they are transported to the processing systems on the Ula platform.