Chrysaor Production is decommissioning the Caister CM offshore platform located in the Southern North Sea, UK.

The platform was used to operate the Caister Bunter and Caister Carboniferous gas and condensate fields in the Southern North Sea. Caister CM is the only platform within the field.

The platform and the associated infrastructure are jointly owned by Premier Oil E&P UK (40%), Chrysaor Beta (30%), Neptune E&P UKCS (21%) and Chrysaor Production (9%).

The application for the cessation of production from the field was submitted in April 2016 and approved in May 2016.

The Offshore Petroleum Regulator for Environment & Decommissioning approved the abandonment of the Caister Field installation and pipelines in March 2020. The decommissioning activities are expected to be completed by 2022.

Details of Caister gas field

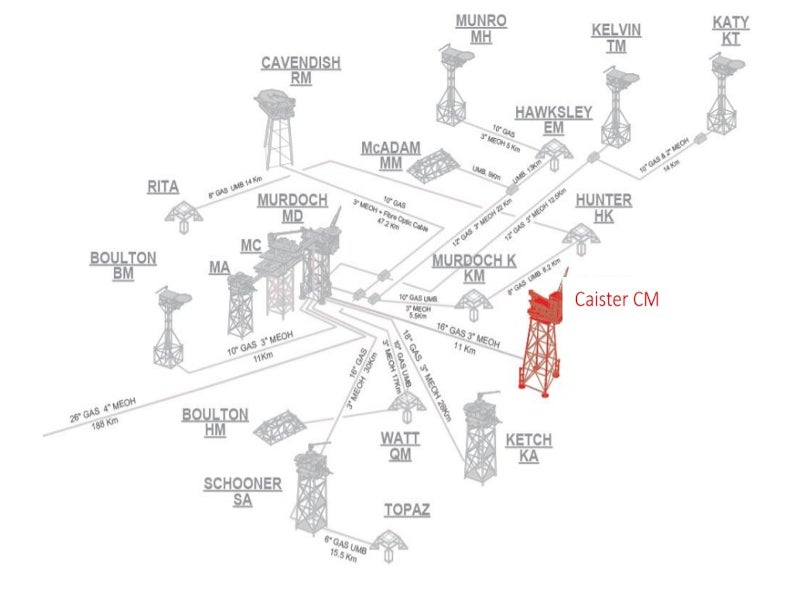

Caister CM platform lies in the Caister Murdoch System (CMS) area, in Block 44/23a in license area P.452, approximately 163km east of the Lincolnshire coast at a water depth of 41m.

The Caister Bunter gas field was developed using three production wells, which included one that was a horizontal sidetrack plugged and abandoned due to problems related to water/sand production.

The 44/23-9 development well of the Caister Carboniferous field was drilled in 1989. The Caister CM platform was installed in 1993 and tied back to the Murdoch Complex via Murdoch MD. The first production from the field started in 1993.

The field has a 16in diameter gas pipeline and a 3.5in diameter methanol pipeline laid up to the Murdoch complex, a manned three jacket bridge-linked complex. The 16in, 11.2km-long gas pipeline is made of steel with coal tar enamel, while the 11.3km-long, 3.5in methanol pipeline is made of steel pipe with fusion bonded epoxy corrosion coating.

The complex transports the gas from Caister platform to the Theddlethorpe Gas Terminal (TGT) in the UK for processing. The topsides and jacket of the platform have a combined weight of 2,696t.

Caister CM platform topside details

Caister CM platform is a normally unmanned installation (NUI). Weighing 1,255t, the topside comprises the main deck, cellar deck and a helideck with the total deck size of approximately 14m × 23.5m.

The topside structure has two main levels and also supports a flare and a single crane.

Caister decommissioning programme

The decommissioning programme was initiated with the flushing of pipelines, using an accommodation work vessel in 2016. The pipelines were left flooded with seawater.

Installations and pipelines to be decommissioned include a fixed steel jacket, four-legged infield satellite platform with eight wells, subsea installations situated 3m below the seabed and drill cuttings piles.

Ensco 92 Jack up Mobile Offshore drilling vessel plugged and abandoned eight Caister CM wells in 2018. The wells were permanently closed by placing the cement plugs.

The topsides will be flushed, purged and cleaned before the discharge of hydrocarbons, produced solids, diesel and lubricating oils. The programme will also include the removal of the jacket via a single lift and the removal of a subsea drilling template.

The piles, which secure the jacket and the subsea drilling template, will be cut 3m below the seabed. The jacket and topsides will be separately lifted and removed and transported onshore for disposal or recycling.

The two trenched and buried sections of pipelines, including the 57m-long riser sections, one for gas and another for methanol, will be dismantled from the platform end.

A seabed clearance survey after the decommissioning activities will look for any debris on the seabed within 500m radius of the Caister platform.