The Cardamom oil and gas field is located in Block 427 of the Garden Banks in the Gulf of Mexico (GoM). It is 100% owned by Royal Dutch Shell (Shell). The 830m-deep field reservoir is situated 362km south-west of New Orleans, US.

The oil field was developed with an estimated investment of $2.5bn. First oil was achieved on 8 September 2014. The project has strengthened Shell’s energy supplies to the US, as well as generated additional jobs for offshore workers.

It was the first project approved by the US Government since the lifting of moratorium on deep drilling in GoM. The moratorium was placed after the Macondo oil spill (Deepwater Horizon) in Gulf of Mexico in April 2010, which has been regarded as the biggest accidental marine oil spill in the history of the petroleum industry.

Production at the Cardamom oil and gas field

Production from the first exploration well started in December 2010. The subsea development produces 50,000 barrels of oil equivalent (boe) a day at peak production. More than 140 million boe is expected to be produced over the field’s lifetime.

Discovery of the field

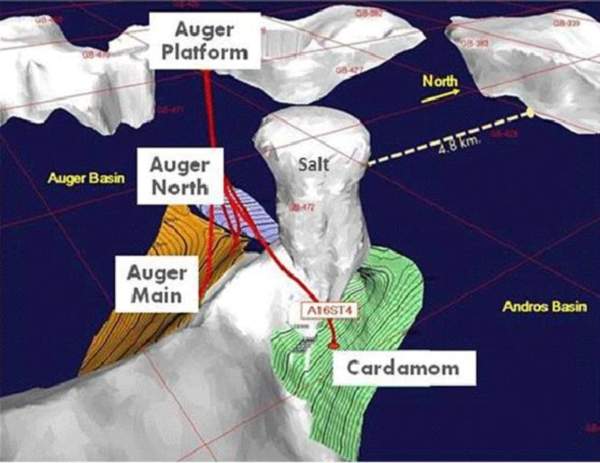

The Cardamom field is located in more than 2,700ft-deep waters in Garden Banks. It was first recognised during the development of Auger field in 1994.

The first discovery well was drilled in 1995 from the existing Auger tension leg platform (TLP), followed by the drilling of second well in the same year.

The presence of oil, however, could not be assessed due to the poor quality of seismic images caused by the nearby salt-layer.

The use of advanced seismic technology helped to produce improved seismic images resulting in the discovery of the Cardamom field at a record depth of 9,642m. Exploration wells were drilled for more than 6.4km below the seabed.

Development of the Gulf of Mexico field

The Cardamom development was approved by the Bureau of Ocean Energy Management, Regulation and Enforcement (BOEMRE) in March 2011.

Shell took the final investment decision on the development in June 2011. The field has been developed as a subsea tie back to Auger TLP to minimise the offshore footprint.

The Auger platform is located approximately 9,200ft west of Cardamom. The platform has been modified in order to handle additional oil, cooling and production capabilities. The modifications included the addition of underwater receiving equipment, a new production train and weight mitigation.

Auger tension leg platform (TLP)

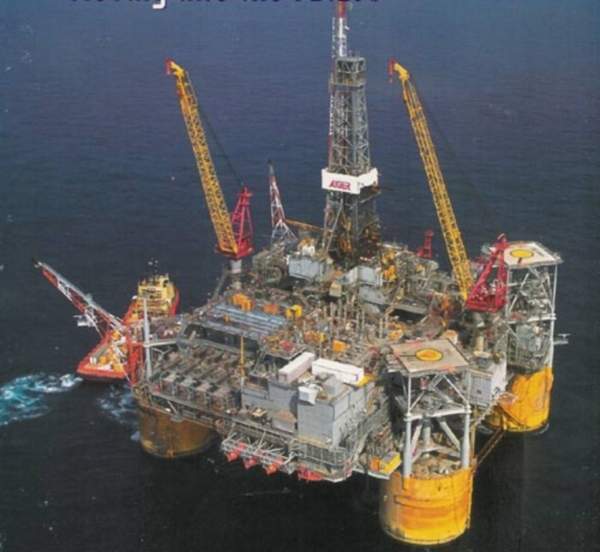

The Auger TLP was designed by Shell. It was the first platform to support drilling rig and complete production facilities in the GoM. It is installed in Block 426 at a depth of 2,860ft. It is 3,280ft tall from the sea floor and weighs 39,000t. It can withstand hurricane force waves of 71ft and winds of 140mph.

The hull weighs 20,000t and comprises four circular steel columns of 159ft in height and 74ft in diameter. The deck is an open truss box steel beam and weighs 10,500t. It measures 290ft x 330ft and is 70ft-high.

The platform is founded on each of its four corners. The foundation consists of a template placed and locked to the piles by hydro-lok connectors. The template frame measures 60ft x 60ft x 30ft. Each template has four piles measuring 72in in diameter and 427ft in length each.

Subsea system

The new subsea system includes five well expandable manifolds, a dual 20cm flowline and eight well umbilicals.

Contracts awarded

The contract to manufacture and supply the subsea and topside systems for Cardamom was awarded to FMC Technologies in December 2010.

FMC supplied five 15,000psi subsea production trees, control equipment, and manifold and tie-in equipment. DUCO, a subsidiary of Technip, was awarded a contract in October 2011 to construct the umbilical.