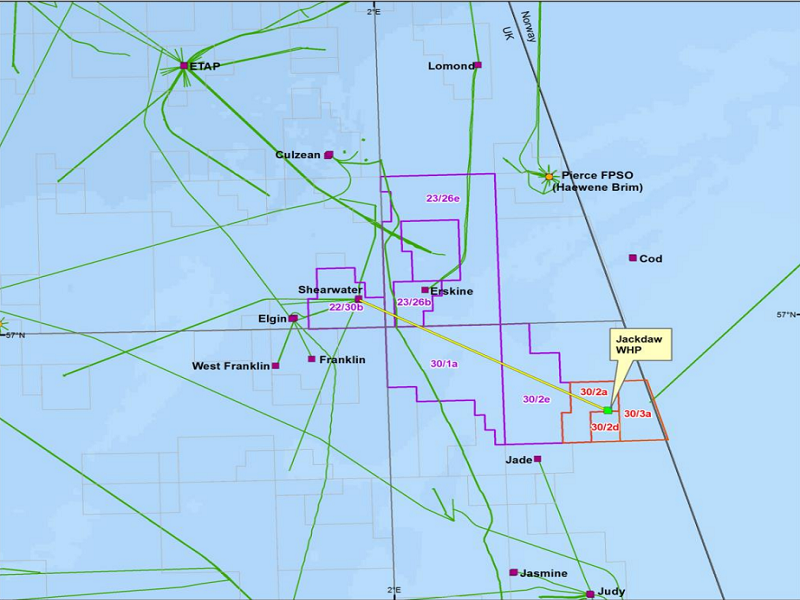

The Jackdaw gas condensate field is proposed to be developed at a water depth of approximately 256ft (78m) in blocks 30/02a, 30/02d and 30/03a of the UK central North Sea. The project location is approximately 250km east of Aberdeen, Scotland and adjacent to the UK/Norway median line.

The gas condensate field lies within the licence areas P098, P672 and P111 and is owned and operated by BG International, an affiliate of oil and gas company Shell’s subsidiary Shell UK.

BG International made the final investment decision for the development of the Jackdaw gas field in July 2022 after receiving approval from the government in the same year.

The field is expected to produce 40,000 barrels of oil equivalent per day (bpd), which is equivalent to 6% of the UK’s North Sea gas production with operational emissions of less than 1% of the entire UK North Sea basin.

The production from the project will cater to the energy needs of 1.4 million households in the UK.

Jackdaw gas condensate field background

Jackdaw field was discovered in 2005 by BG International by the 30/2a-6 exploration well, which intersected hydrocarbons in the Upper Jurassic Heather Formation. The gas field was appraised between 2007 and 2012.

The UK Government’s Department for Business, Energy & Industrial Strategy (BEIS) received the environmental statement (ES) for the field development from Shell in January 2020. However, the timeline of the project was affected by the Covid-19 pandemic, and delays in the project approval process resulted in the Field Development Plan (FDP) being updated.

A new ES was submitted in May 2021, in line with the new Offshore Oil and Gas Exploration, Production, Unloading and Storage (Environmental Impact Assessment) Regulations 2020, which came into effect in January 2021.

Shell filed an application with the UK Oil and Gas Authority (OGA) for project consent in March 2021.

The field is expected to produce its first hydrocarbons between the third and fourth quarters of 2025, according to the revised planned schedule of activities.

Jackdaw gas condensate field details

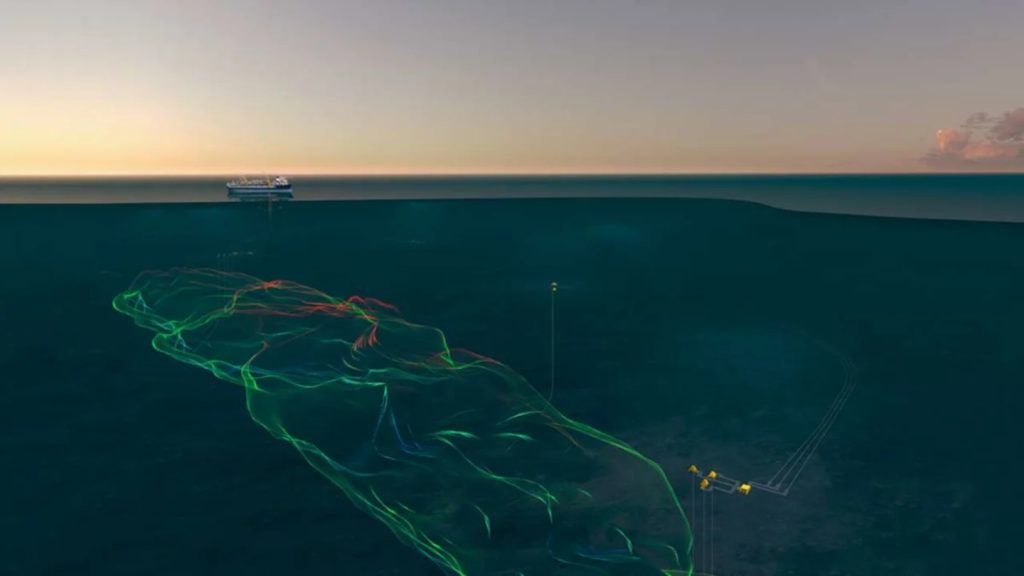

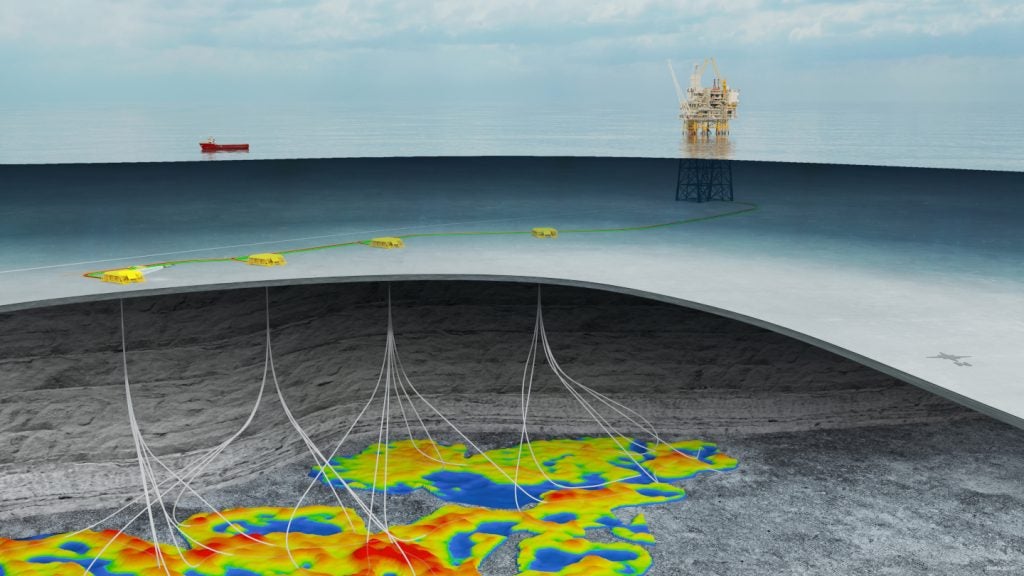

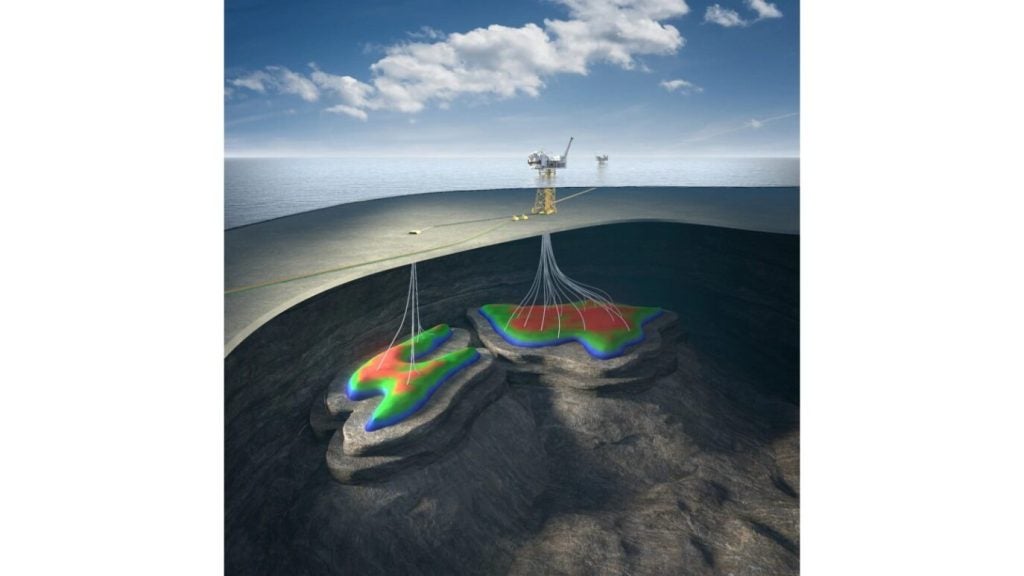

Jackdaw is an ultra-high pressure high temperature (uHPHT) gas condensate field, planned to be developed with four wells connected to a remotely controlled, not permanently attended wellhead platform (WHP).

The field’s reservoir is situated at a depth of approximately 5,182m, with approximately 191°C of temperature and 17,000psi of pressure.

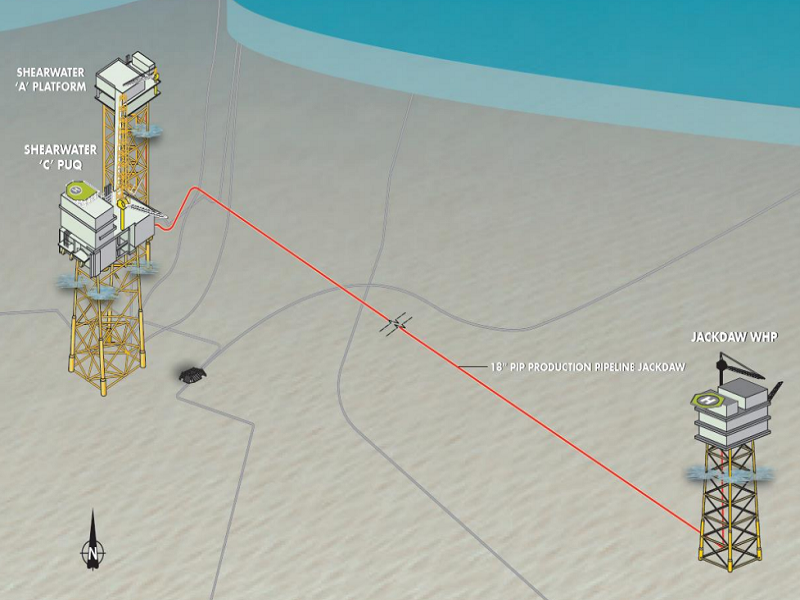

The produced hydrocarbons from the WHP will be exported via a subsea pipeline to the Shearwater platform installed at the Shearwater gas field, located approximately 30km northwest of the Jackdaw field, for processing. The processed gas from the Shearwater facility will be exported to the onshore St Fergus Gas Terminal in Scotland via Shearwater’s export infrastructure, the Fulmar Gas Line while the condensate will be exported via the Forties Pipeline System.

The Jackdaw field development project will help increase the service life of the Shearwater platform, which is key to the potential development of oil and gas discoveries in the Central Graben Area of the central North Sea in the future.

The field is expected to support the realisation of the central North Sea Electrification Project, which aims to cut emissions from the oil and gas infrastructure of industry members in the region through electrification.

Development details

The development plan of the gas condensate field includes the drilling of four new production wells by a heavy-duty jack-up drilling rig. Each well is planned to be drilled to a depth of approximately 6,000m.

A new four-legged steel jacket WHP supporting a topsides module will be installed as a not permanently attended installation (NPAI). It will receive control, monitoring, shutdown and operational support from the Shearwater platform via the WHP Integrated Control and Safety System (ICSS).

An approximately 31km-long with a maximum 18in diameter, 12in new nominal bore pipe-in-pipe pipeline will be laid, connecting Jackdaw WHP to the Shearwater platform. The pipeline will be lined with corrosion-resistant alloy material.

The drilling of the wells is expected to be completed between the third quarter of 2023 and the fourth quarter of 2024. The installation of the platform jacket is expected to be completed by the third quarter of 2023, while the installation of the export pipeline and topsides will take place between the third quarter of 2023 and the first quarter of 2024.

Shearwater platform details and modifications

The Shearwater platform is a fixed manned facility comprising the Shearwater A WHP, connected by an 80m-long bridge to the Shearwater C integrated process, utilities and quarters (PUQ) platform. Production at the Shearwater facility began in 2000.

The gas export capacity of the platform is 320 million standard cubic feet per day (MMscfd) while the condensate export capacity is 99,000bpd.

Minor changes will be made to the platform to support the Jackdaw field development. The Shearwater A WHP will be equipped with new reception facilities, including a new 14in riser and a riser emergency shut-down valve, a blowdown module, utility connections and a connection for temporary pigging facilities.

New telecom antennas, communication and radio equipment will be added to the Shearwater C, in addition to the modification to the acid gas removal unit and piping to support the processing of hydrocarbons from the Jackdaw field.

Contractors involved

Norwegian engineering solutions firm Aker Solutions, previously known as Kvaerner, received the contract to deliver an NPAI in August 2022. The contract includes the engineering, procurement, construction, and installation (EPCI) of the WHP. The company will also be responsible for the associated load-out and offshore hook-up and commissioning.

Aker Solutions was previously contracted for the early front-end engineering design (FEED) study for the gas project in June 2019. The company’s engineering group in Trondheim and Oslo collaborated with Norwegian engineering, procurement and construction company Leirvik and Danish engineering firm Rambøll for the project.

Italian engineering and construction services company Rosetti Marino Group was awarded a contract to perform the FEED design of Jackdaw WHP in July 2019.

Genesis Oil and Gas Consultants, an engineering services and solutions provider based in the UK, acted as the consultant for the preparation of the environmental statement for the project.