Lukoil’s Kravtsovskoye (D-6) oil field is located in the Russian sector of the Baltic Sea. It was discovered in 1983 at a distance of 22.5km from the coast of Kaliningrad region. The depth of the water is 25m to 35m.

The initial exploration drilling followed a geological survey by Lukoil-Kaliningradmorneft. This confirmed that oil reserves of the C1+C2 categories at Kravtsovskoye were estimated to be 21.5 million t. Recoverable reserves were put at 9.1 million t.

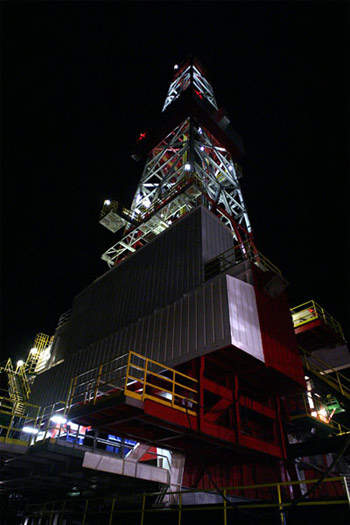

The development is being carried out from an offshore ice-resistant stationary complex manufactured at Kaliningradmorneft steelworks. This is the first production platform in the Russian offshore sector to be designed and manufactured domestically. It has been designed to resist 0.3m-thick ice and survive 9m storm waves.

KRAVTSOVSKOYE OFFSHORE DEVELOPMENT

The development complex consists of two platforms, 11m above sea level, bridge-linked by a 70m walkway. One contains the living quarters, including a helideck, accommodation, eating area, swimming pool and sauna, while the other contains the process and drilling system. 27 wells are planned to be drilled at the field. The average depth of production wells will be 2,160m.

The offshore component of the D-6 project, including the construction of the topsides, was supervised by the Sevastopol-based Corall Central Design Bureau. The electrical switchgear was supplied by Siemens.

The jacket was designed by Krein-Shelf (Kimry Tver region), while the pipeline was deigned by NIPIshelf Institute of Simferopol. The drilling rig came from HRI in Houston. The platform was constructed under the control of Germanischer Lloyd, the Russian marine shipping register and Gosgortekhnadzor.

The topside platform modules were installed on the jacket using the crane-barge Stanislav Yudin.

The first well came on stream in summer 2004 and 70,000t of crude are planned to be produced before the end of the year. By 2007 however, crude production is estimated to reach 600,000t with the rate remaining flat for seven years. The field is expected to last between 30 and 35 years.

COASTAL UNDERGROUND PIPELINE

The offshore facilities are connected to the Romanovo oil-gathering unit on the mainland via a 273.1mm-diameter, 47km-long underwater pipeline. The pipeline has two types of protection: active (it is protected by anodes provided by the Norwegian company Jotun) and passive (a three-layer outer coating). Part of the pipeline lies in an underwater trench and is protected from waves by special constructions. The safety of the pipeline’s ‘technological chain’ is ensured by a reliable control system. The junction of the offshore and onshore parts of the pipeline is equipped with a stop-valve gate for immediate pipeline blocking.

OIL-GATHERING UNIT AND OIL TERMINAL

The coastal underground pipeline consists of two parts. The first part (6.15km long) is an oil pipeline from the stop-valve gate to the oil-gathering unit at Romanovo. The second part (31.6km long) connects the underground pipeline from the oil-gathering unit and the Izhevsky oil terminal. The underground pipeline is equipped with an electrochemical corrosion protection system.

The Izhevsky oil terminal’s tank storage facility will have an aggregate capacity of 120,000m³. After the Kravtsovskoye field is operational it is planned to increase the terminal’s capacity to 4 million t. In future the terminal may boost its annual capacity up to 6 million t.

All industrial and regular wastes from the platform will be transported to the shore for further utilization (zero discharge principle).