Mariner oil field is located approximately 150km east of the Shetland Islands, primarily in Block 9/11a in the northern North Sea, UK.

The field is jointly owned by Equinor (operator, 65.11% interest), JX Nippon (20%), Siccar Point (8.89%) and ONE-Dyas (6%). Developed with a gross investment of approximately $7.7bn, it created more than 700 long-term jobs during its development stage.

A field development plan for the Mariner oil field was first approved in February 2013 and was revised in 2016. The field came on stream in August 2019 and is anticipated to produce more than 300 million barrels of oil over the next three decades.

The annual oil production rate from the field is approximately 55,000 barrels per day (b/d), which will increase to 70,000b/d during peak production phase.

Mariner field location

Mariner oil field is located on the East Shetland Platform of the UK North Sea, approximately 320km north-east of Aberdeen, Scotland.

It is the largest field developed on the UK Continental shelf in recent years.

Mariner field geology details

The oil field in the North Sea was discovered in 1981 and hydrocarbons were identified in the two shallow reservoir sections, Paleocene Heimdal sandstone formation and the Paleocene Maureen Formation, both yielding heavy oil.

The Maureen formation lies deeper at a depth of 1,492m. Hydrocarbons present in the section have 14.2 API gravity and 67cP viscosity, while, the shallower Heimdal reservoir lies at a depth of 1,227m with 12.1 API gravity and 508cP viscosity.

The field is estimated to contain recoverable reserves of up to three billion barrels of oil.

Infrastructure details

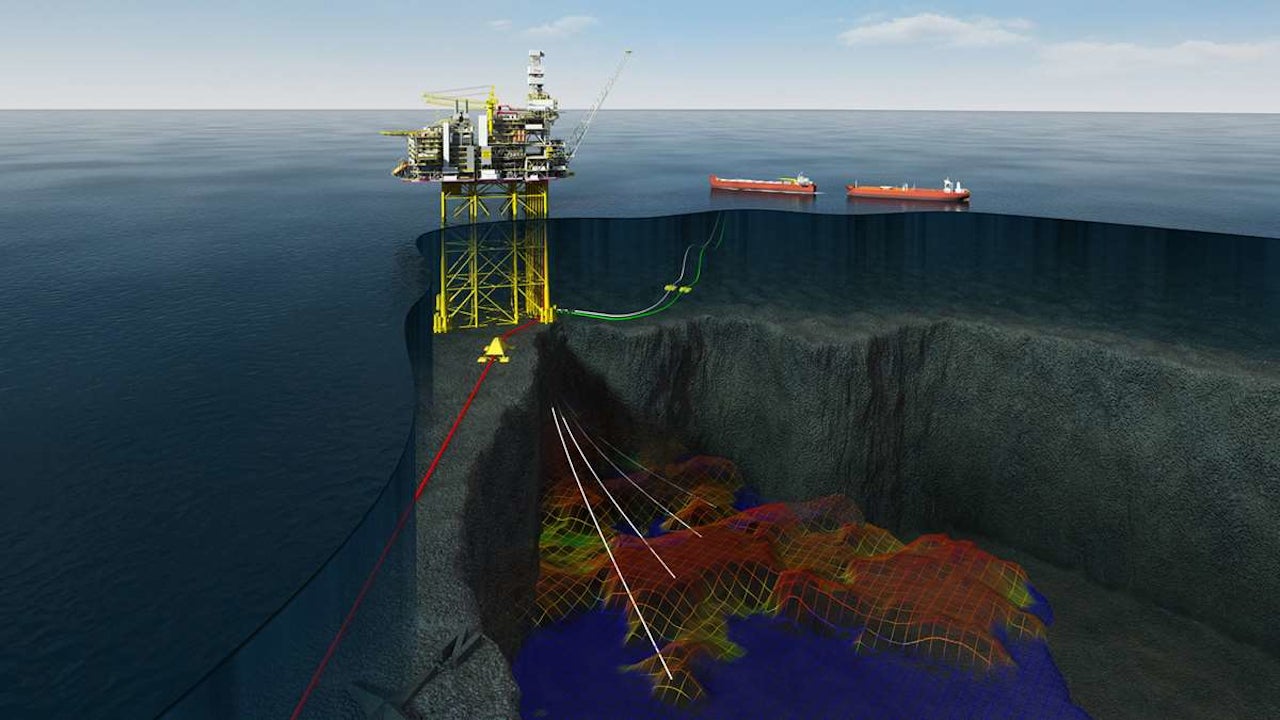

The heavy oil field contains Mariner A, a production, drilling and living quarters (PDQ) platform and Mariner B, a floating storage unit (FSU).

Mariner A was used to perform the initial drilling activities with jack-up rig Noble Lloyd Noble (NLN) during the development. A Safe Boreas flotel was connected to Mariner A by a gangway during the hook-up phase of development to accommodate the extra crew during the final phases of commissioning. It departed the field in September 2019.

Based on a steel jacket, Mariner A rises 254m from the seabed and weighs approximately 40,000t. It was developed by assembling eight large modules. The 255m-long Mariner B FSU arrived at the field in August 2016 and was moored at the submerged turret loading (STL) buoy. It can store up to 850,000 barrels of oil produced from the sea and can remain offshore and operate for 30 years without docking.

A pipeline for gas import connects Mariner A platform to the Vesterled gas trunk-line, while two in-field pipelines connect Mariner A platform to the Mariner B FSU.

Technologies to be incorporated in Mariner oil field

Innovative technologies and digital solutions are being tested to be incorporated in the field. The technologies include automated drilling technology and Echo, a digital copy of the platform.

Contractors involved

Wood entered a three-year agreement worth $75m with Equinor for the operations, maintenance, modifications, and offshore services on the Mariner A platform and Mariner B FSU in October 2020. The agreement will be effective from January 2021 and last until the fourth quarter of 2023.

Samsung Heavy Industries delivered the FSU, while Wärtsilä provided the pumping solutions for the FSU.

Aker Solutions was responsible for the front-end engineering and design (FEED) of the Mariner A PDQ’s topsides as well as to provide maintenance and modification services for the project. The FEED work for the platform’s jacket was performed by SNC-Lavalin.

Subsea 7 won a $170m contract to perform the engineering, procurement, installation and construction (EPIC) of 39km-long rigid flowlines and flexible riser systems, along with related subsea structures, protection systems, and tie-ins in May 2013.

Other contractors involved in the project include Daewoo Shipbuilding & Marine Engineering, Saipem, Dragados Offshore, Odfjell Drilling, Jotun and Schlumberger.