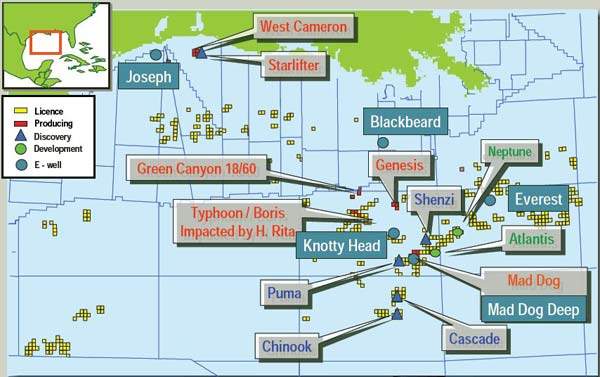

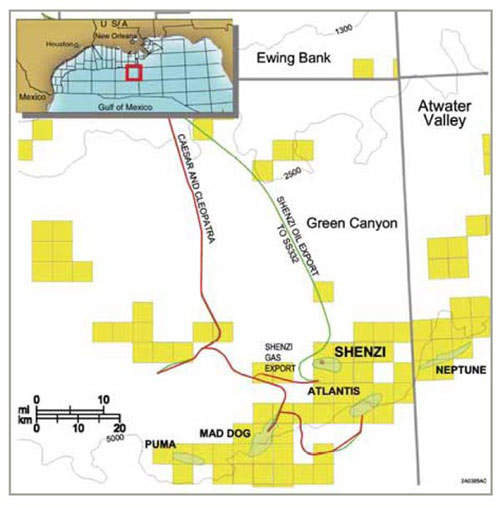

BHP Billiton’s deepwater Shenzi oil and gas field lies in the Gulf of Mexico in Green Canyon blocks 609, 610, 653, and 654, approximately 120 miles from the coast of Louisiana, US. It has a water depth of approximately 1,311m (4,300ft).

BHP Billiton is the operator of the field, with a 44% stake, while Repsol and Hess each have 28% stakes.

Shenzi holds an estimated recoverable reserves of between 350 million and 400 million barrels of oil equivalent, although additional potential reserves will be targeted for follow-up development. Gross costs for the full field development until 2015 have been put at $4.4bn.

BHP Billiton announced its first oil and natural gas production from the Shenzi development in March 2009.

Production at the Shenzi field exceeded its capacity during September 2009. It produced 120,000bopd against its capacity of 100,000bopd.

The field has two more wells, which are currently shut down and are available for generating additional output whenever required. The field has 15 wells under the project.

Shenzi deepwater oil and gas drilling

Shenzi-1, which was drilled in 2002, encountered a gross hydrocarbon column of 142m (465ft) with a net pay of 42.5m (140ft). This was followed by Shenzi-2 in 2003, which encountered a 381m (1,250ft) gross hydrocarbon column and 152m (500ft) of net oil pay in lower Miocene sandstones.

Shenzi-3, drilled by GlobalSantaFe’s drillship CR Luigs in May 2004, encountered hydrocarbons in lower Miocene-aged reservoirs with approximately 100m (330ft) of net oil pay in a 125m (410ft) gross hydrocarbon column.

In October 2009, Repsol discovered additional reserves within two wells at the field. Repsol reported a 100ft oil column discovery in the Shenzi-8 appraisal well, which was drilled in November 2008.

An additional 555ft oil column was also discovered in the existing G-104 well.

In May 2011, BHP Billiton brought a new well, SB-201, onstream at the field. It is Shenzi’s 11th well. Drilled to a depth of 25,126ft, the well is producing at the rate of 17,000bopd.

BHP Billiton received approval to drill another well, SB-101, in June 2011. Full field development will include up to 15 producing wells.

Shenzi field development

The Shenzi field has been developed by a standalone tension leg platform (TLP). The TLP has a nominal capacity to produce up to 100,000 barrels of oil and 50 million cubic feet of gas a day on a 100% basis. The facilities, wells and completions are proven designs that have been successfully implemented in the deepwater Gulf of Mexico. The TLP design is a Modec International Moses Class platform.

The topsides deck weighs 8,684t and the 12,493t hull gives a total weight of 21,177t. The tendons weigh 1,329t and the piles weigh 433t.

The topsides, measuring 4m by 59m by 19.2m, is spread over three decks. It is supported by a four-column hull with each column measuring 10.4m by 8.8m and standing 54m high. There are four pontoons and eight (4×2) tendons 36in to 44in in diameter. The 357 tendons connected by oil states connectors, will reach 1,311m (4,300ft).

The topsides were fabricated by Kiewit Offshore at Ingleside, Texas, while the hull was fabricated by Samsung in South Korea. They were assembled by Heerema and transported by Dockwise in a dry tow.

Subsea development

INTEC Engineering was awarded the deepwater subsea development execution support contract, a continuation of engineering support that commenced with pre-feasibility, FEED and detail engineering.

The subsea development includes three main drill centres supporting up to 15 oil wells. Initial production is routed through four manifolds via four production SCRs.

The INTEC scope for this work includes the detailed design of the Shenzi infield risers, flowlines, manifolds, rigid pipe jumpers, gas-lift distribution units, thermal analysis, support for the invitation to bid and technical review of bids, technical review of third-party designs, and subsea equipment installation support.

Technip was awarded a contract by BHP Billiton for the flowlines risers and subsea structures installation.

The contract covers the engineering, fabrication and installation of a system of two infield flowlines and six flowlines welded to steel catenary risers and connecting three drill centres to the production platform.

Pipeline End Terminations design was carried out at Technip’s operations and engineering centre in Houston. The flowlines and risers were welded onshore at Technip’s spoolbase in Mobile, Alabama, minimising the duration of offshore operations.

Offshore installation was carried out in 2008 by Deep Blue using the reel-lay process.

Shenzi oil exports

Shenzi oil is exported via a newbuild pipeline to Ship Shoal 332, which was completed in April 2009 by Enterprise Products Partners.

The 20in-diameter line is 83 miles long and has a capacity of 230,000bpd of crude oil. It connects to the partnership’s Ship Shoal 332B junction platform, giving Shenzi producers access to the Enterprise-operated Cameron Highway Oil Pipeline and Poseidon Oil Pipeline systems.

Natural gas is exported via a newbuild lateral into a connection in the Cleopatra trunk lines, then on to Ship Shoal 332. The 12in-diameter Cleopatra pipeline will be 11 miles long and BHP Billiton has a 22% equity share in the project.