Tambar oil field is located in production licence PL065 in the Norwegian part of the North Sea, in a water depth of 68m.

Aker BP is the operator of the field and holds 55% interest, while Faroe Petroleum Norge holds the remaining 45% interest.

The field is remotely operated from the Ula field located 16km south-east of the site, and has been producing since 2001.

The developers announced a NOK1.7bn ($199m) extension project in March 2017, which will aim to extend the life of the field up to 2028.

Production from the extension is scheduled to commence in 2018.

Tambar oil field discovery

Tambar field was discovered with the drilling of the 1/3-3 discovery well by the Borgsten Dolphin semi-submersible drilling rig on 22 August 1982.

The well was drilled to a depth of 4,876m and encountered oil in the Triassic sandstone.

An eastern extension of the field was discovered in 2007, which is known as Tambar East.

Geology and reserves at Tambar field

The field’s reservoir is located at a depth between 4,100m and 4,200m with good properties, and contains Upper Jurassic sandstones of the Ula Formation.

Tambar field was estimated to contain 13.6 million standard cubic metres (Sm³) of recoverable oil equivalents upon discovery, and an estimated 1.2 million Sm³ of reserves still remain at the site.

The Tambar East reservoir is believed to have originated in Late Jurassic age, and is located at a depth between 4,050m and 4,200m.

The field was originally estimated to contain recoverable oil equivalents of 0.3 million Sm³ but this estimate was later revised ad reduced, as production has not met initial expectations.

Details of Tambar platform

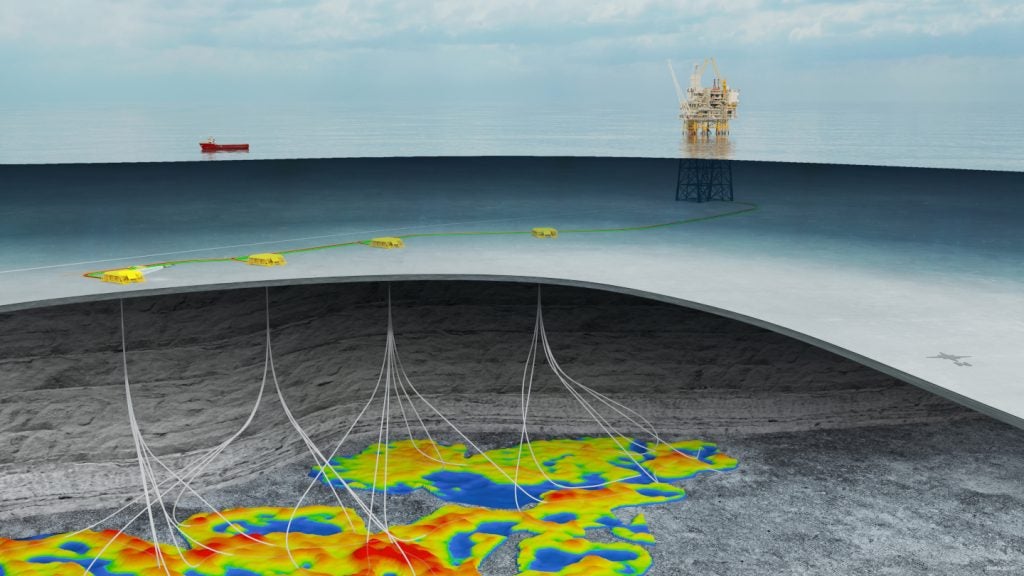

The Tambar platform is a normally unmanned wellhead platform (NUI) and is operated remotely from the Ula field.

It is a steel wellhead structure with no processing facilities. Power is supplied to the facility via a submarine cable from the Ula field.

Tambar field development details

Hydrocarbon resources at Tambar are recovered through natural pressure depletion, along with gas expansion and limited aquifer drive processes.

The produced oil is sent to the Ula field through a subsea pipeline where it undergoes processing, before being exported by a pipeline system through Ekofisk to the Teesside region in the UK.

Produced gas is then pumped back into the Ula field reservoir in order to boost oil production.

The field was initially produced through three wells, two at Tambar and one at Tambar East, though increasing water-cut has reduced production, resulting in just one well currently being active.

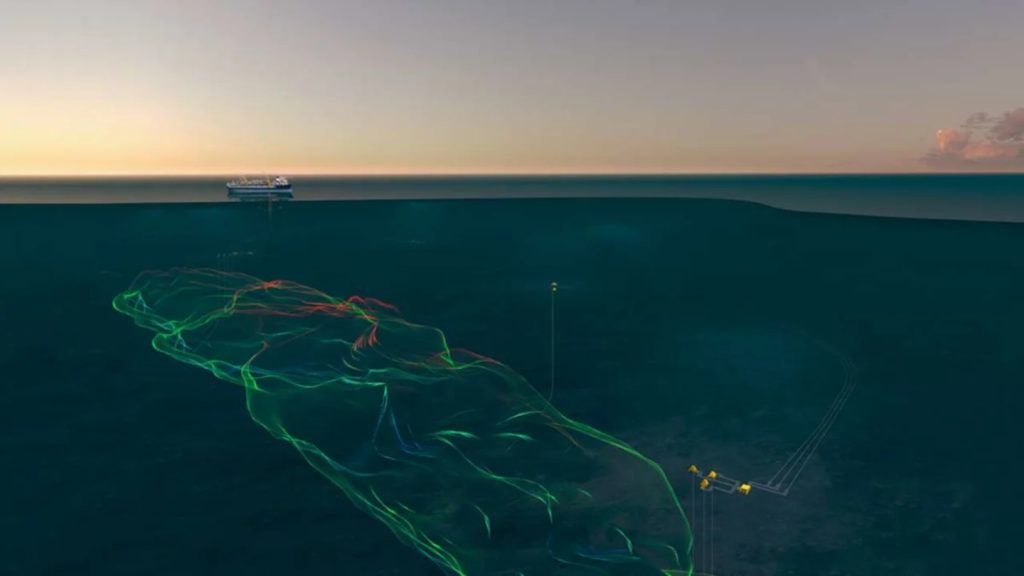

The developers carried out a 4D seismic survey aimed at estimating the reserves in the northern part of the field and improving reservoir management in 2014.

An extension project is being undertaken at the field based on data recovered from the survey.

Tambar field extension project details

The field extension development is also known as the Tambar Artificial Lift (TAL) project, and aims to achieve a production rate of 4,000-6,000 barrels of oil a day.

The project includes the drilling of up to five production wells and two infill wells through the remaining drill slots on the Tambar platform. It will also involve gas lift from the Ula Gyda Interconnector Pipeline (UGIP).

Wells will be drilled by the Maersk Interceptor drilling rig in the fourth quarter of the year. The drilling activities will also be used to test the oil-water contact in the northern part of the field reservoir.

Modifications to the Tambar platform and the Ula platform will also be carried out; the piping and equipment, including the deluge system, and gas lift flowlines and valves will be modified to ensure measurement and transportation of lift gas.

The support systems will also be upgraded and flowlines will be connected to the new wells, with a conductor guide structure also being planned for installation under the platform.

The UGIP at the Ula field will be modified to terminate at the Tambar platform.

Gas metering, piping and valves will also be upgraded at the Ula platform.

The developers have also evaluated other options for the field extension, including water injection and drilling of an infill well at Tambar East.