Opus provides innovative solutions for produced-fluids treatment and oil and gas separation to enhance the throughput and environmental performance of production facilities.

From its UK bases in Orkney and Surrey, Opus offers oil and gas operators the expertise and facilities to embrace all aspects of produced water treatment and oil and gas separation, providing a comprehensive resource from the initial concept through to commissioning.

Changes in flow conditions over a field’s lifetime can substantially affect the performance of assets. Bespoke solutions from Opus meet all conditions encountered. Verified by experienced personnel and a combination of visual dynamic modelling (VDM) and computational fluid dynamics (CFD), each solution provides assurance for both current and future case conditions. Opus manages the design, fabrication, installation and commissioning of all its technology.

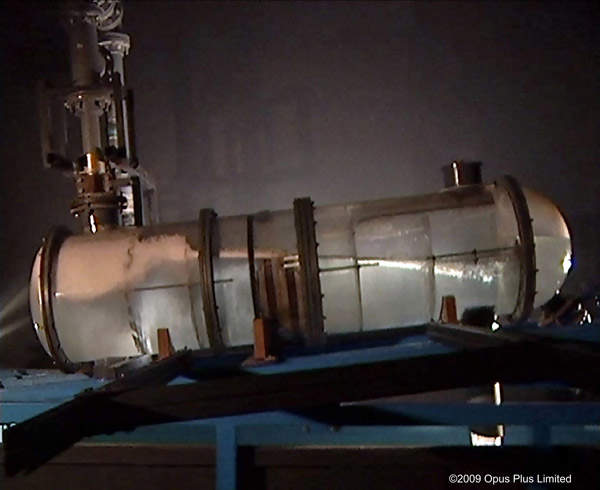

Compact flotation unit

Opus compact flotation technology is a multi-phase separator that has no moving parts and does not require any external energy. Compact, cost-effective, and easy to install and maintain, the Opus compact flotation unit (CFU) offers numerous additional benefits to meeting offshore industry regulations. Package supply, installation and commissioning is ensured by a dedicated project team. Features include:

- Easy and stable operation

- Performance maintained at turndown conditions

- High flow capacity

- Insensitive to motion, proven performance on floating production systems

- Handles high solids loading

- Robust performance in slugging flow and variable inlet oil content

- Operates at low pressure; can operate at higher pressures

- Adaptable skid layout to suit installation and restricted access

- Low operator intervention

- Designed for retrofit on to existing platforms

- Inter-stage or pre-stage coalescence with the Opus Mare’s Tail®

Oil coalescer

The Mare’s Tail coalescer was developed to meet a recognised need from the industry for an efficient, cost-effective technology to coalesce small oil droplets and thus improve the removal of oil from produced water.

The Mare’s Tail coalescer can be easily retrofitted into existing installations or fitted as part of a water treatment package for a new installation. The Mare’s Tail technology offers a number of key benefits to the end-user, including:

- Tolerant to high solids loading

- Improves the quality of produced water

- Enhances the performance of existing water treatment technology

- Extends the turndown

- Unaffected by heave or roll, making it ideal for FPSO applications

- Compact and easy to install and maintain

- Cost-effective, best-available technology

- Self cleaning

- Media replacement does not require vessel intervention

Process equipment upgrade

Whether multiphase separators, gas scrubbers, flare drums or produced water systems, Opus provides the dedicated management, expertise and technology to ensure the successful upgrade of process equipment.

Opus considers all aspects of an upgrade project to ensure that core problems are identified and solved. A wealth of experience means Opus engineers know where to look, what to look for and which technology is best employed. From survey to study phase, through to implementation, Opus unearths the problems and applies the solutions. Opus solutions can:

- Enhance system performance

- Increase throughput and product quality

- Maintain cost-effectiveness

- Provide effective troubleshooting

- Improve produced water quality

- Manage transient conditions (slugging / surging)

- Optimise chemical treatment

- Improve operability

Opus internals technology and validation methods are robust and proven in the field. The combination of experience, skills and technology allows Opus to meet and exceed client objectives while achieving cost-effective results.

Opus’s quality management system has been registered by National Quality Assurance under the provisions of BS EN ISO 9001.