Rising Stem Ball Valves (RSBV)

Control Seal’s non-contact RSBV has a single-seat friction design that enables an exceptionally long life span even under extreme conditions.

Control Seal is the industry leader in tailor-made, high-integrity special valves, with over 30 years in valve manufacturing experience and 100 years in precise engineering.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Control Seal has more than 30 years of experience in the valve business and over 115 years in precise engineering, which started as Brons Motoren Fabriek. Having its facility located in Appingedam, The Netherlands, Control Seal thrives to be more than a valve manufacturer and become a reliable valve solution provider.

Control Seal’s product range consists of Dual Expanding Double Block and Bleed Valves (DBBV), Rising Stem Ball Valves (RSBV), Axial Flow Valves (AFV), Four-Way Diverter Valves (4WDV), Axial Check Valves (ACV), Butterfly Valves (BV), Globe Control Valves (GCV) and more.

Control Seal’s products are well-known and appreciated by major EPC contractors. Control Seal is registered as an approved vendor in more than 200 companies.

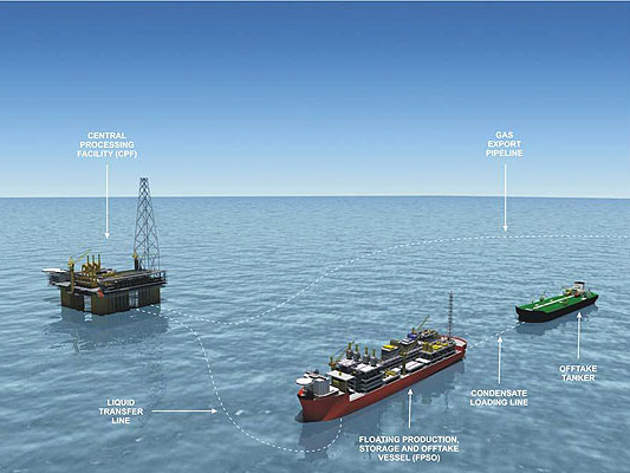

Control Seal’s valves are used worldwide, including offshore environments with the most extreme conditions.

Control Seal developed the Double Block and Bleed Plug Valve (DBBV) in the 1990s due to market demand for a friction-free bubble-tight shut-off valve, which reduces space requirements while requiring little or no maintenance. Control Seal’s DBBV gives a 100% bubble-tight sealing upstream and downstream, an excellent solution for DBB and DIB function in pipeline systems. Control Seal is the original developer of the Helixtrunnion® system.

Therefore, the industry requires a strict shut-off for valves with upstream and downstream sealing. Control Seal’s DBBV functions upstream and downstream, which would normally only be achieved by using two valves and a spool piece with a drain valve.

One of the crucial parameters that determine the lifetime of a valve is the sealing mechanism. Conventional vales have a sealing mechanism based on shear force, which results in wear and tear.

However, Control Seal’s DBBV was created to combat this issue of wear and tear. Control Seal’s DBBV’s sealing mechanism is based upon a radial movement only. The sealing is not liable to shear, friction or tear. In other words, there will be no abrasion on the seal and boast an exceptionally long lifetime, compared to other conventional valve types.

Control Seal’s DBBV is designed for easy and low-cost maintenance. Furthermore, bottom and top access are possible while the valve is in-line. No special tools are required.

Control Seal’s DBBV is easy to operate, and all kinds of actuators are compatible with the valve thanks to its Helixtrunnion® mechanism.

Control Seal DBBV is fire-safe certified according to BS6755 part 2 and API6FA standards by an independent inspection agency.

A unique feature of Control Seal’s DBBV is its backseat design. This allows servicing the stem packing while the line is under pressure. The integrity of the backseat has been tested by means of an extended test after fire-safe testing.

The self-locking operating mechanism on Control Seal’s DBBV prohibits the plug from rotating due to in-line forces. Therefore, there is no danger of line slam or shock.

Control Seal’s Non-Contact, Friction-Free Rising Stem Ball Valve (RSBV) has a single-seat friction-free design. Designed for frequent switching and fluctuating temperatures, they are also recommended for emergency shut-down and blow-down service.

Control Seal has also developed a non-contact RSBV designed for sand slurry applications with a sand content of +/-50%.

RSBV has a sealing mechanism based upon axial movement only, which is not liable to friction or tearing. This friction-free quarter-turn mechanical energised sealing means no abrasion on the seal and an exceptionally long lifetime, compared with other types of valves. Control Seal is the original developer of Helixstem®.

The stem of the Control Seal’s RSBV makes a small axial movement only when opening or closing. The stem is always balanced. No stem rotation occurs in combination with axial movement when opening or closing.

The stem packing of the RSBV can be adjusted while the valve is in service. All valves are executed with a backseat.

Control Seal’s RSBV is designed for easy and low-cost maintenance. Furthermore, bottom and top access are possible while the valve is in-line. No special tools are required.

Control Seal’s RSBV is easy to operate, and all kinds of actuators are compatible with the valve thanks to its Helixstem® mechanism.

Control Seal offers various types of Axial Flow Valves (AFV), namely Axial On-Off Flow Valve, Axial Control Flow Valve, Axial Flow Surge Relief Valve and Axial Chock Flow Valve, which all ensure precise control of pressure and temperature and flow with a compact design.

Quarter-turn stem design enables the eccentric disk connected to the rotating system to move the piston rod practically frictionless, compared to a gear-rack which loses more than 50% of its thrust.

Furthermore, bubble-tight dual sealing up to ANSI FCI Class V or VI is achieved.

Control Seal was awarded ISO 15848 certification among the first vendors in the industry. Following this guideline, Control Seal covers its complete range of products to class BH, and some even to class A. ITIS BV successfully tested Supagraf® Premier in Control Seal valves for fugitive emissions according to ISO 15848-1 2006 CO2 Class A. This is the lowest rating of leakage defined under ISO 15848-1. This leakage limit was only reserved for bellowed sealed valves until then. This result demonstrates a change in the performance of braided graphite packing in relation to fugitive emissions.

Unlike many, Control Seal valve designs are operated purely by linear movement of the stem (no axial rotation), which ensures reduced wear and tear on the stem packing, resulting in minimum fugitive emissions.

While other valve manufacturers are claiming that they are ‘hydrogen-ready’, Control Seal is beyond the ‘ready point’. They are experienced since 2001 in more than 24 countries worldwide when it comes to hydrogen. Recent projects in which Control Seal was involved are Bapco’s Modernization Project (500+RSBVs were delivered), Crude Flexibility Project in Abu Dhabi, and Hengli Hydrogen Project in China (180+ RSBVs were delivered).

Control Seal’s non-contact RSBV has a single-seat friction design that enables an exceptionally long life span even under extreme conditions.

Control Seal’s DBBV is a friction-free bubble-tight shut-off valve, using Helixtrunnion® rotating mechanism, developed by Control Seal in the 80s.

Control Seal offers Axial on-off flow valve, Axial control flow valve, Axial flow surge relief valve, and axial choke flow valve, which ensures precise control of pressure, temperature, and flow with a compact design.

Control Seal’s 4-Way Diverter Valve (4WDV) was developed for strict requirements of bi-directional meter proving.

The Knarr oil and gas field, located in the Norwegian North Sea, is planned to be decommissioned by 2028.

The BassGas project, including the offshore Yolla field in the Bass Basin, will be expanded with the Yolla West infield development.

Barzan Gas Project is a vital project expected to sustain and fuel the ongoing and future major infrastructural projects in Qatar.

The South Pars field located in Iran is the northern extension of Qatar’s giant North Field. It covers an area of 500 square miles and is located 3,000m below the seabed at a water depth of 65m.

The Ichthys field is situated on block WA-285-P in the Browse Basin, Timor Sea, Western Australia. The gas and condensate field lies at a water depth of 280m.

Bayu-Undan is located 500km offshore Darwin, Australia, in the Timor Sea, and is 250km south of East Timor.

Discovered in July 2000, Kashagan was described as the largest field found in the past 30 years, the largest outside of the Middle East, with a projected output close to that of the Ghawar field in Saudi Arabia.

Kvitebjørn field is situated in block 34/11 of the Tampen area in the North Sea, Norway. The gas and condensate field lies at a water depth of 190m.

Goldeneye is located 100km northeast of St Fergus. It was discovered in October 1996 with the drilling of well 14/29a-3

The Snorre field lies in blocks 34 / 4 and 34 / 7, approximately 200km west of Floro in the Norwegian North Sea.

Control SEAL will be attending and exhibiting at Rio Oil and Gas 2012 at Centro de Convenções, Rio de Janeiro, Brazil.