32-Inch CRA-Lined Pipes: Advancing Performance for Offshore & CCUS Applications

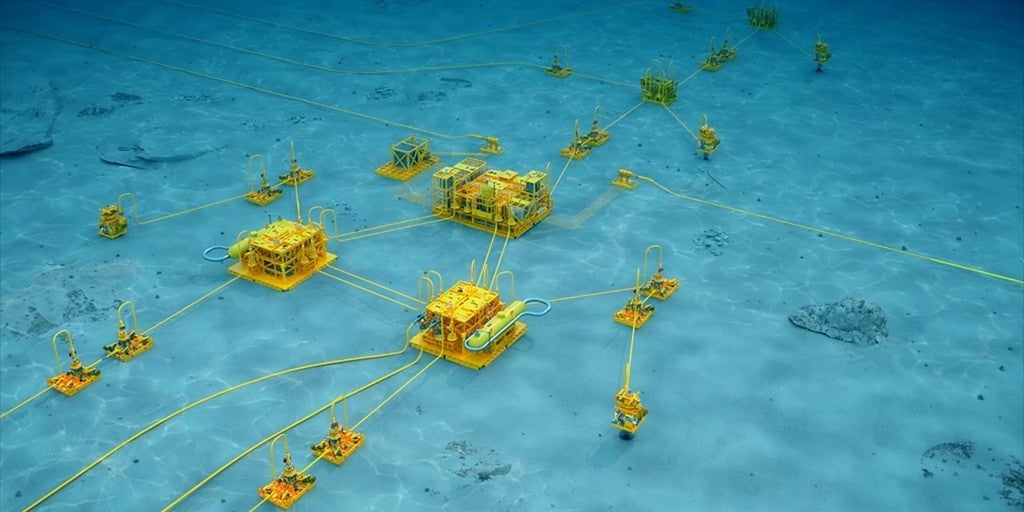

Corrosion-resistant alloy (CRA) materials play a pivotal role in submarine pipelines, addressing internal corrosion caused by transported fluids.

Cladtek specialises in Mechanically Lined Pipe (MLP) and weld overlay cladding for a wide range of applications.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Cladtek Holdings Pte offers comprehensive corrosion resistance solutions where CRA piping products are required for industries such as offshore, onshore, as well as subsea and subsurface applications, geothermal, carbon capture and hydrogen storage. This includes pipes, fittings, flanges, pressure vessels, hot induction bends, CRA-lined OCTG, fabrication services, and connected, reusable flowline and riser systems.

With manufacturing facilities strategically located in Indonesia, Brazil, and Saudi Arabia, Cladtek delivers cost-effective, high-quality, localised solutions with timely delivery worldwide.

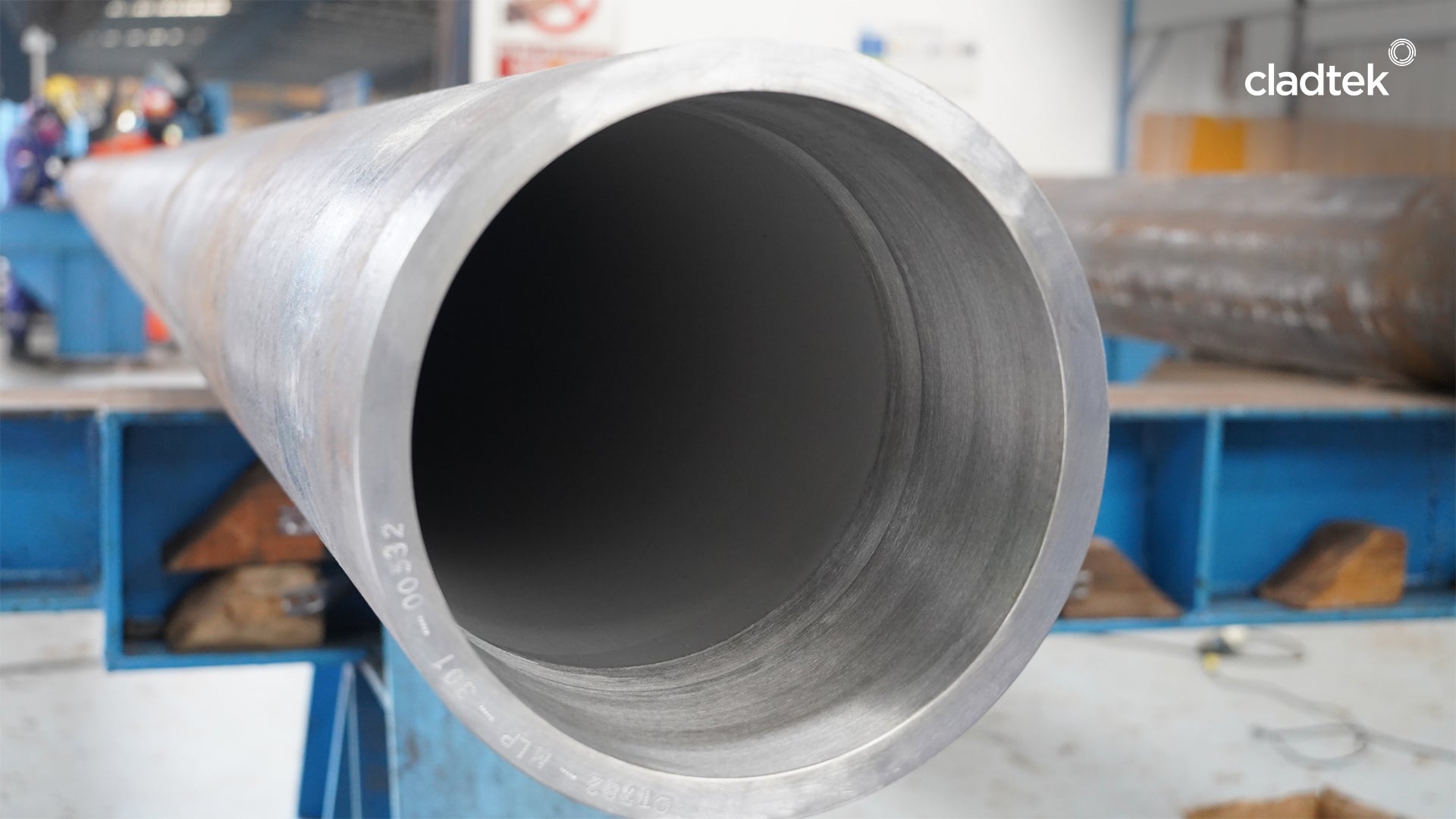

There is a continued requirement for cost-effective pipeline solutions that can withstand harsh operational environments. Cladtek’s MLP technology combines the benefits of a corrosion-resistant CRA liner with the strength and longevity of a carbon steel carrier pipe, delivering enhanced performance and cost-efficiency.

This solution can operate in high temperature, high pressure and highly corrosive conditions. It is designed for durability, rapid installation, and reduced operational costs.

MLP is also applicable in renewable energy sectors, supporting advancements in hydrogen storage and transfer, geothermal energy, and Carbon Capture, Utilisation, and Storage (CCUS).

One of Cladtek’s notable projects is the HiSep project, where advanced weld overlay solutions protect critical components against corrosion in high-pressure, high-temperature subsea operations, enabling increased output from the processing facility.

Key advantages of Cladtek’s solutions:

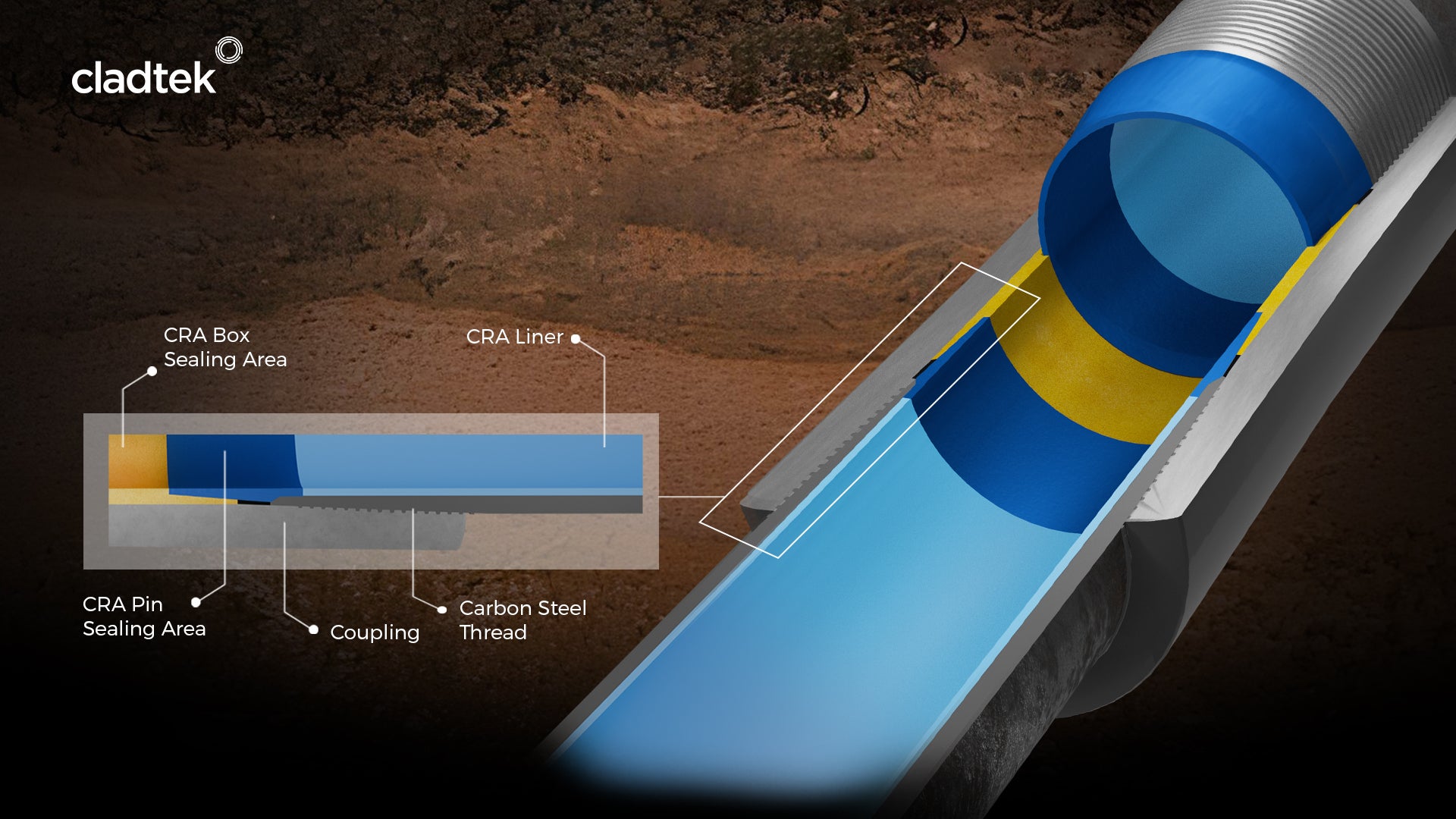

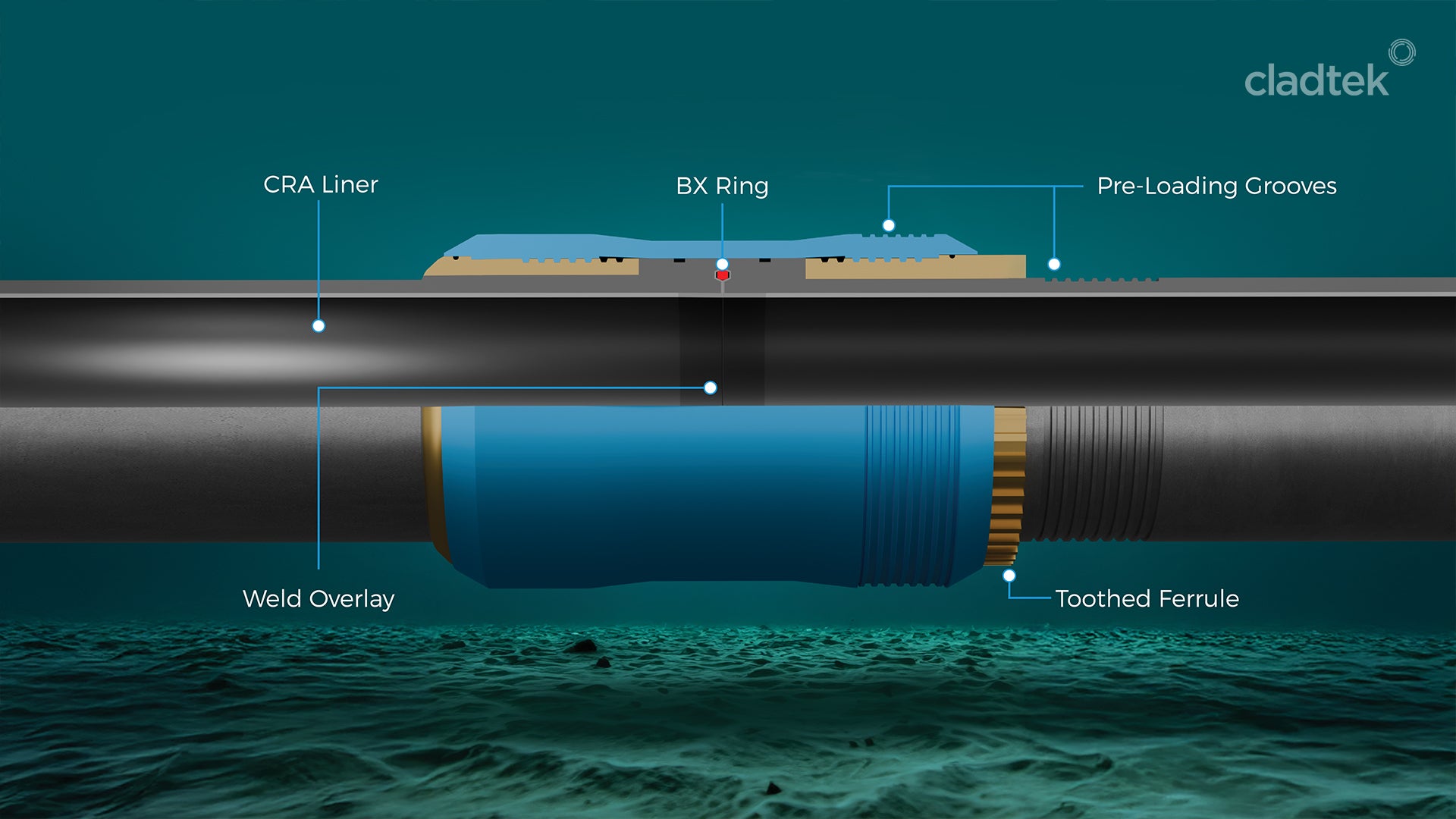

Cladtek continues to innovate by developing advanced solutions tailored to the new energy sector. The company has introduced technologies such as Mechanically Lined Tubular (MLT), a CRA-lined OCTG solution and the RapidPipe Connector, designed for risers and pipelines where vessel availability is limited and welding is impossible or problematic.

Cladtek has established itself as a reliable partner in the energy sector for over two decades, delivering high-quality, cost-effective CRA solutions that can be applied in the oil and gas industry. The company’s success is driven by diverse projects, continuous innovation, and investment in workforce development.

Through training programmes and partnerships, Cladtek supports local talent and industry expertise, contributing to economic growth and sustainable development. These partnerships are integrated into Cladtek Academy, closely connected with the company’s three manufacturing hubs in Batam, Rio de Janeiro, and Dammam.

Cladtek is also committed to engaging with the communities where it operates. This approach has led to the development of robust apprenticeship programmes in collaboration with several educational institutions. The company has established partnerships with more than 14 universities, provided over 140 industry accreditations, and supported a local workforce of more than 2,000 employees across 17 nationalities.

Cladtek’s commitment to excellence was recognised with the SBR National Business Award in 2024 for its iN-Shield programme and the ESG Initiative of the Year award at the Asian Oil & Gas Awards in 2022.

Cladtek’s CRA solutions are particularly useful in offshore applications as they offer extended lifespan of products, service reliability for clients around the globe, advanced safety features, and an environmentally sustainable mindset that drives the company’s commitment to high product quality.

Beyond innovation, Cladtek prioritises a safe, inclusive, and empowering workplace, aligning with organisational goals. The company is committed to sustainability by using low-impact materials, adhering to strict environmental regulations, and minimising waste.

Safety remains a core focus, with rigorous standards in place to protect employees, partners, and the community. Cladtek’s solutions are designed for long-term reliability, minimising environmental impact through sustainable manufacturing practices.

With strategically located manufacturing facilities, Cladtek supports its local economies and communities, providing local content support and solutions to those who value them. The company serves a diverse client base, including major energy companies, fabricators, and EPC contractors, leveraging its global footprint in Indonesia, Brazil, and Saudi Arabia.

Cladtek is a trusted partner for energy companies around the world, collaborating with Saudi Aramco, Petrobras, Pertamina, ExxonMobil, BP, Chevron, Eni, and TotalEnergies.

By combining local capabilities with global expertise, Cladtek fosters growth and innovation while maintaining long-term partnerships. The iN-Shield program ensures consistent quality and operational excellence across all operations.

Cladtek’s values emphasise fostering a culture of unity, excellence, sustainability, innovation, and value. The focus is on developing processes and technologies to provide reliable and sustainable solutions that support the evolving needs of the offshore and other energy sectors.

With 20 years of experience, the company has advanced the cladding industry by investing in Research, Development and Innovation (RD&I) to stay responsive to market trends through the energy transition. Cladtek has achieved several key milestones, from being the first to apply weld overlay to the ends of Mechanically Lined Pipe (MLP) to producing the smallest and largest MLP and creating the largest weld-overlayed fitting in the world.

Corrosion-resistant alloy (CRA) materials play a pivotal role in submarine pipelines, addressing internal corrosion caused by transported fluids.

Innovation is the driving force behind the energy industry and one of Cladtek’s core values. The constant pursuit of technological advancements and cost-effective alternatives pushes this sector to develop groundbreaking solutions that revolutionise the market.

The energy sector has historically been marked by a predominance of men. However, new initiatives focused on diversity have been gaining ground in the market, contributing to the creation of more inclusive work environments for women.

ladtek is proud to announce that we have received the Best Execution Winner in the Oil & Gas Equipment Industry at the 10th Annual Strategy into Performance Execution Excellence (SPEx2®) Award, held on June 26, 2025, at Le Meridien Jakarta.

Cladtek has been recognised with the Business Eminence Award 2025 by Dun & Bradstreet Singapore, which highlights companies demonstrating strong financial performance, sustainable growth, and sound business practices.

Cladtek introduces a new inclusion program aimed at hiring and training people with disabilities for technical roles starting at its facility in Rio de Janeiro, Brazil.

Cladtek has been awarded a contract by TechnipFMC for Petrobras’ inaugural HISEP® project to be deployed in the Mero 3 field.

Cladtek has been awarded a contract by Allseas to supply 120km of Inconel 625 Mechanically Lined Pipes (MLP) for the Búzios 10 project.

PT. Cladtek Bi-Metal Manufacturing, a leading provider of corrosion-resistant products, celebrated the commencement of manufacturing for the South Senoro Project (Phase II) flowline materials.

Oil and Gas exploration in Brazil’s Pre-Salt region boasts one of the lowest carbon footprints in the industry, despite the challenging environment and the corrosive, CO₂ and H₂S-rich reservoirs.

Cladtek Holdings is pleased to announce its recognition at this year’s SBR National Business Awards in the Manufacturing category for our iN-Shield initiative, a pivotal component of our Global Transformation program.

Cladtek announced its recognition by the Stellar Workplace Awards 2024 for its commitment to employee engagement and satisfaction.

At Green Rio 2024, Cladtek joined as a co-host together with AEDIN Associação Empresas Distrito Ind in Santa Cruz to showcase sustainable solutions and explore opportunities for investment in the circular economy.

Cladtek announced the signing of a new collaboration agreement with Mitsui and Nippon Steel Corporation (NSC) to strengthen their presence in the Corrosion Resistant Alloy (CRA) Linepipe (LP) market and to better support the growing demands.

Cladtek successfully completed the final shipment for the Ndungu Field Development Project, contracted by Azule Energy Angola S.p.A., delivering over 41km of Corrosion Resistant Alloy (CRA) Mechanically Lined Pipes (MLP), in addition to weld overlay pipes, hot induction bends, and pup pieces.

Mechanically Lined Pipe (MLP) has emerged as a leading corrosion-resistant pipeline solution, combining the strength of a carbon steel carrier pipe with the corrosion-resistant properties of a CRA liner.

Clad pipes and fittings are essential for both oil and gas and renewable energy industries, offering unparalleled resistance to corrosion and extreme conditions.

Cladtek’s Mechanically Lined Tubulars (MLT) combine the strength of a carbon steel outer layer with the corrosion resistance of a CRA lining, offering a cost-effective, durable, and high-performance alternative to solid CRA tubulars.

The RapidPipe Connector is an innovative, high-performance system designed for pipelines and risers, offering cost-effective, durable, and sustainable connections.

As a leader in Corrosion-Resistant Alloy (CRA) solutions, our expertise covers all CRA cladding requirements, from pipe and fittings to induction bending and pipe spool fabrication.

Cladtek provides a comprehensive range of independent testing and simulation services to support the pipeline industry.

Cladtek is a global leader in corrosion-resistant alloy (CRA) clad solutions. As one of the world’s leading suppliers, we provide comprehensive, advanced CRA manufacturing solutions. Join us as we push boundaries and set new industry standards.

Cladtek is dedicated to reducing its environmental impact, fostering an inclusive and supportive workplace, and upholding the highest ethical standards.

Cladtek’s RD&I division combines expertise with advanced technologies, solving complex challenges for industries ranging from oil & gas to renewable energy.

Cladtek’s Built iN-Quality (BIQ) initiative aims to embed quality assurance into all of Cladtek's facilities, capturing defects at their point of origin to prevent downstream impacts.

Cladtek's RapidPipe connector is a robust and cost-effective system designed for pipelines and risers.

As part of our commitment to industry growth, Cladtek Academy plays a key role in developing future talent through school and community programs, contributing to a sustainable and skilled workforce.