B.Metal performs assembly, monitoring and testing of offshore mechanical structures. Its highly specialised staff work on-site at the company’s 10,000m² facility. Services are carried out in accordance with the standard UNI EN ISO 9001:2000 and UNI EN ISO 14001.

B.Metal operates principally in the following areas:

- Development of technical documents, such as drawings of existing plants where these are not available

- Building of piping, carpentry, heating, etc.

- Assembly (maintenance of rotating machines, general maintenance of industrial plants and equipments)

- Coordination of services and in situ supervision of maintenance work

- Providing civil and industrial plants

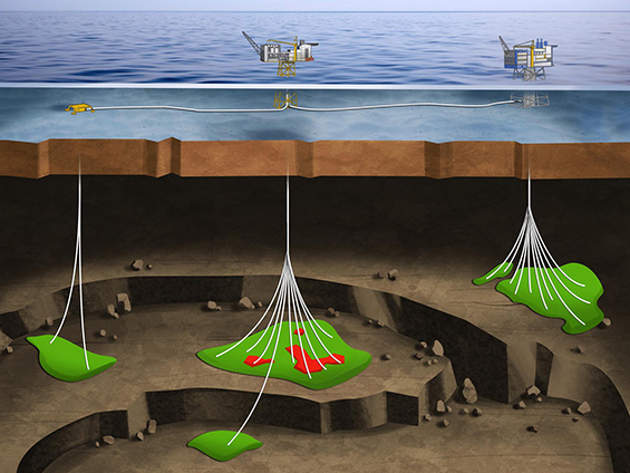

- Construction of offshore plants, water ducts, sewage plants and gas ducts

- Manufacture, assembly and testing of 800t cranes, including cabin control, arm and rotating parts

- Skid pumps, air compressors and oil lubrication centres

Metal cutting and shaping

Cutting is the first stage of processing to make every project precise. B.Metal employs highly specialised staff and advanced machinery on a useful 12,000mm by 3,000mm floor area. The company can make cuts of any size with classic computerised belt miter saws, disc-cutting chop saws, acetylene torch beams and plates, and pantographs with benches for numerical control.

In additional to cutting and shaping, B.Metal also provides sheet and metal plate bending up to a 100mm thickness with a last-generation MH4-roll MG rolling press.

Carpentry

Specialised B.Metal workers employ carpentry to prepare handmade products for welders. They carry out step-by-step assembly of various elements that vary in size and thickness for a range of different technical projects.

Carpentry is a crucial phase for the final outcome, with precision and attention to detail essential for the installation of structures all over the world.

Piping

Piping is the specialised part of carpentry. B.Metal produces piping in any size and type for the chemical, petrochemical, steel, thermal ecology and aqueduct sectors. It provides joints for glass, socket, rapid and flange soldering and production accessories such as faucets, gates, manometers, safety valves and condensers. The company always verifies the seal based on characteristics requested by the client, and tests using high-pressure equipment.

Welding

Welding is the most delicate and important part of the engineering sector. Each type of material and thickness must be treated with great care and accuracy to certify and guarantee seal, durability and accuracy of the work which was ordered.

B.Metal deals with all kind of soldering using cutting-edge technologies, including submerged-arc with a manipulator, continuous wire (FCAW), and TIG. It ensures constant quality control through the use of non-destructive testing (NDT).

Sandblasting and painting

The phase following metalworking consists of solder dross cleaning and the removal of oil, grease and various kinds of stain.

B.Metal’s 600m² booth with aspiration allows greater abrasive power, dust collection and recycling for painting and iron grit sandblasting after cleaning. The booth is equipped with a bridge crane at an 8m working height, with an overall depth of 18m by 30m.

Equipment handling and shipping

Having a large (around 500m) space available for the storage of handmade articles in an area near the industrial port of Arbatax offers B.Metal a privileged position for handling and shipping to final sites.

B.Metal is capable of handling any weight and shipping anywhere in the world, including for third parties. The company uses cranes, off-road vehicles and forklifts in all sizes for shipping, as well as multi-purpose trailers manufactured in-house.

B.Metal produces five different kinds of trailer according to the needs required. These range from the STD80 (80t) through the STD200, STD300 and STD400 medium-sized trailers up to the impressive STD600 (600t). Highly useful for moving heavy objects around building yards, the trailers are manufactured in motorised and radio-controlled versions to allow easy and precise transporting.

Please use the form below to send B.Metal your business enquiry.