The TCC® technology is used on other materials than drill cuttings. Biological sludge from refineries has been dried on a commercial basis. Bio sludge with up to 95% water has been dried in a 630kW unit. Among new areas that are looked into are oil contaminated soil, refinery tank bottoms and production waste.

500°C process temperature is sufficient evaporation temperature for most hydrocarbons. A process temperature of 500°C in a TCC® is equivalent to a heating media temperature between 550°C and 600°C in an indirect drier. In addition, the TCC® benefit more of steam stripping than other technologies because of the forced homogenous mix of steam and oil vapours.

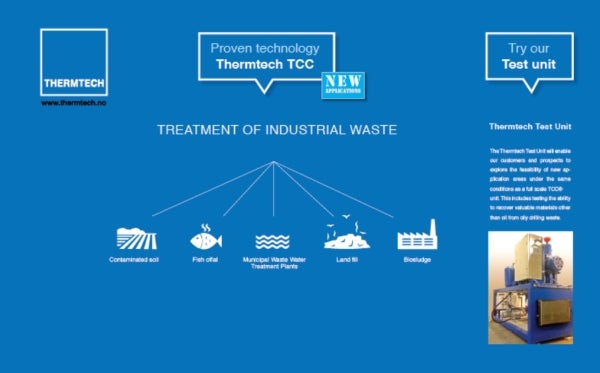

A number of different materials have been tested in the TCC®. Some tests have been carried out in full-scale units and some in the test unit. Some tests are stunt tests and some more comprehensive. A number of tests have been carried out in cooperation with clients.

To know more about the countless new applications of the Thermtech TCC®, please visit us at Offshore Europe, in Aberdeen, UK, from 8 to 11 September 2015.