Acoustic Leak Detector

During last November, CO.L.MAR. has been present in two very important events.

Co.L.Mar is a specialist provider of acoustic subsea leak detection equipment such as the underwater acoustic hydrophone.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Co.L.Mar is a specialist provider of acoustic subsea leak detection equipment. One of the company’s most recent and featured products is the underwater acoustic hydrophone, which allows for the effective detection of sound propagation in a liquid setting.

The company has been operating in the marine industry since 1982 and is experienced in acoustic engineering and geophysical investigations. Co.L.Mar is certified ISO 9000 – 2015.

Co.L.Mar. has released an acoustic subsea leak detection system ALD® (acoustic leak detector) which is able to locate very small leaks on the sea line even in extremely hard environmental conditions. After the first leak detection, back in 1998, the technology and the relative service have been developed for many years and an international patent has been obtained.

It is currently one of the fastest, most accurate and reliable methods for sea line leak inspection, especially when an emergency occurs. We are an international leader in this specialist area thanks to our decades of experience and history of delivering proven leak-detection solutions.

Since 2017, the ALD® technology has been qualified by DNV ‘for locating leaks in subsea pipelines and installations’. Our products, such as the underwater acoustic hydrophone for offshore applications, provide opportunities for a variety of applications that require subsea detection.

In the many offshore inspection projects we have worked on worldwide, we have been able to detect leaks as small as 0.04lt/minute.

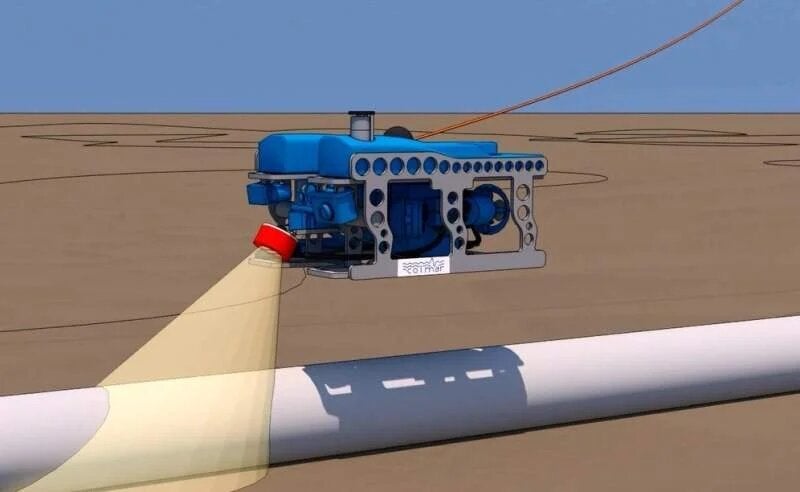

The ALD® underwater pipeline leak detection system features an underwater sensor that collects acoustic data as it scans the pipeline. The acoustic data is transferred online to an onboard receiver, then to a PC, where it is analysed, displayed and recorded by proprietary software.

Compared with other leak detection techniques, ALD® has the following advantages:

During years of development, different underwater leak detection and inspection techniques have been defined:

Additional sensors integrated into the main system are available depending on the cases:

Colmar is probably the company that has detected the largest number of leaks in subsea installation, in 2023 thus number reached the value of 60. This is very large considering how rare is a leak event.

We have detected leaks worldwide, from the Caspian Sea to Borneo, from the USA to China and West Africa. We have been working under the ice or over 2.000m depth.

We have detected leaks on many different structures including:

One of the most featured products by Co.L.Mar is the underwater acoustic hydrophone, which essentially refers to the study of acoustic waves in liquid environments and relates to the top-quality subsea detection services that the company already provides.

Designed to be either passive or active sensors according to the client’s application needs, the underwater acoustic hydrophone basically functions as a technology dependent on their intrinsic noise as well as the sea noise level. This allows the hydrophones to be versatile and can be applied explicitly to the oil and gas sector for offshore applications as they can be used both for shallower waters and deep water environments.

Clients will be specifically drawn to the customised nature of the hydrophones, their precision when it comes to noise detection, and their widespread application for a variety of subsea projects, which benefit from Co.L.Mar’s patented Acoustic Leak Detector technologies for subsea leak detection.

Hydrophones vary from low-noise and omnidirectional ones to digital hydrophones and many more.

During the hydrotest of subsea installation, a leak contingency plan has to be put in place. This traditionally consists in injecting fluorescine or other kinds of dye and then proceeding with a visual inspection if required.

But in this case, very often the visual inspection fails because leaks on new installations are typically very small (FJ solder crack or leaking flange) and spotting any sign of dye became impossible. Not to mention if visibility is poor or some current burial is present. As a consequence, we are often called out on a very urgent base after the failure of the hydrotest of the traditional visual inspection.

For this reason, many clients contract us to standby on-site during any hydrotest so that, with a small cost they can have the best leak detection service guaranteed in case of need.

Also, dyes are pollutants and in many areas of the world are interdicted, while ALD has zero environmental impact.

So we can provide a more effective and environmentally friendly leak contingency plan during pre-commissioning.

On the base of the experience gained in subsea leak inspection, we have recently developed a system for permanent monitoring of the most critical areas of subsea installation: manifolds, wellheads, valves, etc.

The system is composed of one of the more intelligent sensors to be installed subsea and of a surface station for settings and alarm generation. The subsea units are designed for a 25-year life expectancy with no maintenance and an operating depth of 3,500m.

During last November, CO.L.MAR. has been present in two very important events.

Co.L.Mar has been a leading provider of subsea leak inspection services for almost two decades, using an innovative acoustic leak detection (ALD) system that is continuously being upgraded to incorporate the latest research and technologies.

With ever-increasing attention being paid to the environment and pipeline integrity, the importance of using effective subsea leak detection and leak monitoring technology is enhanced.

Co.L.Mar. Srl specialises in underwater acoustics and in 1998 it started to apply this technology for subsea inspection to detect leaks on pipelines and other pressurised installations.

The advantages of using sound to take measurements and transmit data underwater are well known.

Co.L.Mar, based in La Spezia, specialises in underwater acoustics which, since 1998, have been applied to underwater leak detection for use on pipelines, risers, flanges and other structures.

In the offshore industry, once a new oil and gas pipeline is completed it has to go through a check known as a 'hydro-test' prior to commissioning.

Pipeline leaks involve the transition of the fluid from the internal pressure to the lower external pressure.

Co.L.Mar's Acoustic Leak Detector (ALD) technology has pinpointed defects on three subsea pipelines in a variety of settings.

Passive acoustics is probably the most reliable technology for subsea leak detection.

The system division of Italy's Atos has developed a compact jacking system for offshore handling operations on platforms, drilling rigs, and vessels.

We briefly review the capabilities of the Co.L.Mar acoustic detectors designed for oil and gas leakages from the offshore pipelines.

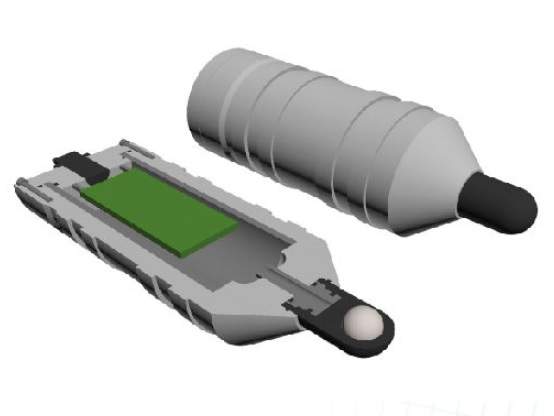

The ALD-PIG is an autonomous version of the Acoustic Leak Detector to be inserted in a foam PIG and record data along the pipelines to be tested.

The Mafumeira Sul project is the second phase of development of the Mafumeira field located in the Cabinda province of Angola.

Zohr Gas field is located within the 3,752km² Shorouk Block, within the Egyptian Exclusive Economic Zone (EEZ), in the Mediterranean Sea.

Discovered in July 2000, Kashagan was described as the largest field found in the past 30 years, the largest outside of the Middle East, with a projected output close to that of the Ghawar field in Saudi Arabia.

The Siakap North-Petai (SNP) field is located in block K on the west coast of Sabah in Malaysia.

The Al Wasit Gas Program includes the development of Arabiyah and Hasbah gas fields located offshore Saudi Arabia in the Arabian Gulf. The project is being developed by Saudi Aramco and is scheduled to be commissioned in 2014.

The Liwan 3-1 gas field sits in licence block 29/26 in the South China Sea, 350km south-east of Hong Kong in the Pearl River Mouth Basin.

Co.l.Mar. Italia is thrilled to announce its participation in Oceanology International 2024, the premier global hub for ocean technology.

Co.l.Mar. Italia proudly takes centre stage at the 35th Annual European Cetacean Society Conference in Catania, Sicily, Italy, showcasing its cutting-edge hydrophone technology.

The ALD-PIG is an autonomous version of the Acoustic Leak Detector to be inserted in a foam PIG and record data along the pipelines to be tested.

On the 14th of June 2021, Colmar has completed the acquisition of the Acoustic Calibration Pool facility.

Co.L.Mar is pleased to announce that its subsea acoustic leak detector (ALD®) system received formal certification from DNV GL in December 2017.

Colmar delivers the first ALD-AUV version to a major oil company.

One of our ALD® teams was recently called out in the Middle East for a leak inspection on new subsea installation, including a 16in line and a number of flanges protected by shorouds.

CO.L.MAR. exhibits at oceans15, in Genova, Italy, from Monday 18 to Thursday 21 May 2015.

After winning an international bid, acoustic subsea leak detection equipment provider Co.L.Mar has been awarded a two-year frame agreement contract with Saipem Spa for the provision of subsea leak inspection services.

Co.L.Mar, a provider of acoustic subsea leak detection equipment, has released a free white paper on Offshore Technology.

Colmar Srl has recently signed an agency agreement with Dovaheights Energy.

Co.L.Mar. and ExxonMobil confirmed its participation in the third Subsea and Artic Leak Detection Symposium (SALDS), which will be held in Houston, Texas, on November 8-9, 2011.

Having ALD® equipment and personnel on site during a hydrotest allows for leak inspection to start immediately if needed. The request for preventive leak detection is growing rapidly. In the first months of 2011 we have completed two projects: Co.L.Mar. has been contracted by BJ Servic

The ALD system in ROV and diver version is equipped with an additional channel which can now host a hydrocarbon detector: the Turner Design – Cyclope 7. The sensor detects crude oil with a minimum detection limit of 0.1ppm. It is now possible to run an acoustic and optical inspection of the pipel

ALD® has been recently optimised for use with divers. This technique is suitable when inspecting flanges, valves or short segments of pipelines. Two solutions are available: ALD DIVER: the diver handles the sensor and drives it around the flange to be inspected, data are sent by a soft

Co.L.Mar has won a new project for ALD: a new success for us and excellent business for our customer. A new, 20km pipeline was found to be leaking during the final hydrotest. After adding dye, the ROV visual survey gave no result. ALD was then mobilised ALD which detected the leak during the ver

A new project for ALD: a new success for us and an excellent business for our customer. A 60km pipeline from shore to 60mt was leaking. ALD in the towed fish configuration was mobilised and once the inspection started, the leak was detected within 12 hours. The position of th

On 9 October 2008 ALD was installed on a Seaeye Coguar ROV for inspecting a well head in the Adriatic Sea. The well head had already been inspected visually without results. In less then one hour ALD detected a leak signal and pinpointed the leak at the back of the control POD. The leak could the

Following a 3-year development period the new ALD digital version has been completed. The performance improvements exceed expectations: Data are immediately converted to digital format: noise on trasmission line (ROV) is minimised New software version introduces the “C

Co.L.Mar’s patent-pending Acoustic Leak Monitor (ALM) leverages the company’s cutting-edge Acoustic Leak Detector® (ALD) technology to identify fluid leaks within marine structures in precise and reliable manner.

Co.L.Mar’s DNV GL–certified Acoustic Leak Detector® (ALD) is an innovative solution designed to accurately and efficiently detect leaks in a wide variety of marine environments.