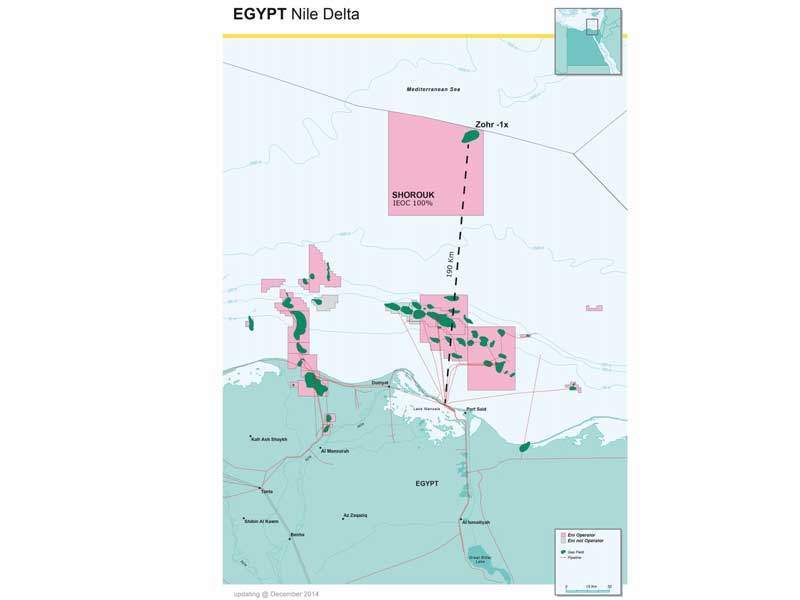

Zohr Gas field is located within the 3,752km² Shorouk Block, within the Egyptian Exclusive Economic Zone (EEZ) in the Mediterranean Sea. The field is situated more than 150km from the coast.

Eni owns a 100% stake of the Shorouk licence through IEOC Production, and the property is operated by Belayim Petroleum Company (Petrobel), a joint venture between IEOC and Egyptian General Petroleum Corporation (EGPC).

Eni was granted approval for the Zohr Development Lease by the Egyptian Natural Gas Holding Company (EGAS) in February 2016. The deepwater gas field started production in 2017 and reached full production capacity in 2019.

The overall investment in the Mediterranean offshore gas project is estimated to be approximately $12bn, with the initial investment to bring the gas field into production estimated to be approximately $4bn.

Discovery and appraisal

The gas field was discovered in August 2015 by drilling the Zohr 1X NFW well at a water depth of approximately 1,450m (4,757ft). The exploration well was drilled to a total depth of 4,131m (13,553ft) and encountered 630m (2,067ft) of hydrocarbon column.

The field was appraised in February 2016 by drilling the Zohr 2X appraisal well, approximately 1.5km south-east of the exploration well.

The appraisal well was drilled at a water depth of 4,800ft and to a total depth of 4,171m (13,684ft), encountering 455m (1,614ft) of continuous hydrocarbon column. It produced approximately 44 million standard cubic feet a day (MMscfd) of gas during the production test.

Geology and reserves

The Zohr prospect is characterised as a Lower-Middle Miocene Carbonate reservoir, hosting a biogenic gas accumulation within a tertiary source rock, which is sealed by the Messinian Evaporitic complex (also known as the Rosetta Formation).

The deepwater field is expected to hold approximately 30 trillion cubic feet of lean gas, making it the biggest gas discovery in the Egyptian Mediterranean Sea. The reservoir further has upside potential at the deeper Cretaceous target.

The gas produced from the field is distributed within Egypt, while the excess will be exported to overseas markets.

Development

Phase I of the project included the development of six production wells to produce an initial 1bcf/d of gas in 2017, and reached its peak production capacity of 2.7bcf/d in August 2019.

The project involved the construction and installation of an offshore control and production platform, which is further connected to an onshore processing plant by means of subsea pipelines.

The peak production was achieved following the completion of eight land-based treatment units and the systems for treatment and removal of sulphur. Three more wells and a second 30in gas pipeline, extending up to 216km and connecting the underwater production installations to the land-based treatment plant also contributed to the increase in production.

The full field development plan entails the drilling of 254 wells over the field’s production life.

Contractors involved

The exploration and appraisal wells were drilled deploying the Saipem 10000 ultra-deepwater drilling vessel.

One Subsea was retained for the $170m engineering, procurement, construction (EPC) contract for the project’s first phase. The company earlier performed the front-end engineering design (FEED) study for the project.

Aker Solutions was awarded the Nkr1bn ($122m) contract for the delivery of approximately 180km of steel tube umbilicals, which connected the subsea wells to the offshore platform.

Salzgitter Mannesmann International, a subsidiary of Salzgitter Group, as well as EUROPIPE, and Mülheim an der Ruhr, a joint venture of the Salzgitter Group and AG der Dillinger Hüttenwerke, were contracted to supply approximately 227km-long and 26in diameter pipelines for the project.

Bonatti International performed electrical and instrumentation works for the project. Spina acted as a specialist in providing solutions for industrial plant engineering. PJ Valves manufactured over 4,000 valves, managed bulk handling, and inspection and packing.

Petrobel was the main contractor for the second phase of the project. Enppi provided engineering services, while Baker Hughes provided subsea technology services.