Wakefield Acoustics is a leading manufacturer and supplier of advanced industrial and environmental noise control systems to the offshore industry.

With more than 35 years of experience of supplying bespoke industrial noise control solutions, the company has developed an extensive knowledge of high-specification NORSOK-compliant noise control solutions. These include bespoke blast rated acoustic enclosures with fire and gas detection and suppression systems, as well as electrical installations, along with a wide range of fully welded silencers and other ancillary equipment.

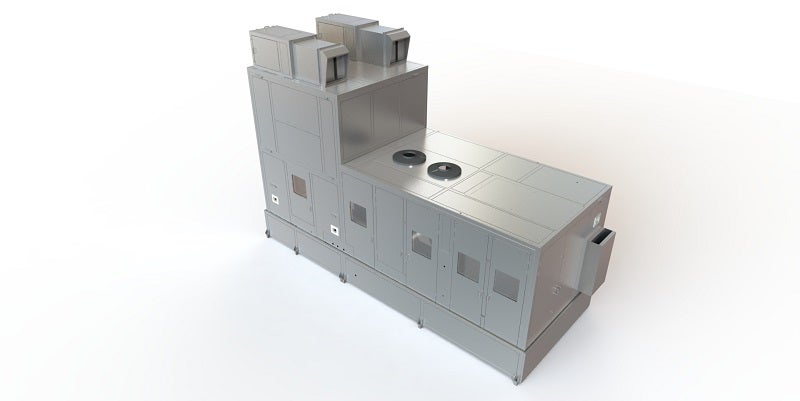

Packaged acoustic enclosures for adverse offshore environments

Wakefield Acoustics designs, manufactures and installs an extensive range of bespoke packaged acoustic enclosures, which can be fitted within onshore or offshore hazardous area applications.

Applications include skid-mounted and deck-mounted acoustic enclosures, and skid-mounted screening. Usually manufactured from 316L stainless-steel for the offshore industry, Wakefield Acoustics’ product range can also be supplied in pre-galvanised mild steel, along with a variety of finishes to accommodate the demands of extreme environmental conditions. High-specification paint systems that comply with ISO12944 C5M (offshore environments) are also available.

To support plant access and maintenance requirements, the company’s acoustic enclosures can be designed and supplied with a wide variety of access and viewing options, including single and double leafed doors, hinged and sliding doors for personnel access, and various viewing options.

Wakefield Acoustics’ enclosures are designed, manufactured and transported in a modular framework, and factory fitted with full electrical systems to meet physical size, height and weight specifications, as well as transportation requirements.

Hazardous area compliant mechanical and electrical systems

Wakefield Acoustics has extensive experience of supplying hazardous area compliant acoustic enclosures incorporating comprehensive ventilation and electrical systems.

Depending upon the application, this can include hazardous area complaint ventilation (ATEX) and filtration, full electrical fit-out terminated at internally or externally mounted junction boxes; hazardous area lighting and emergency back-up lighting; as well as fire and gas detection and suppression systems, which can comprise water mist or water deluge via an internally mounted pipework distribution.

Wakefield Acoustics also supplies blast-rated acoustic enclosures supported by finite element analysis and full structural design capability.

High-specification welding and fabrication

Wakefield Acoustics employs a highly skilled workforce many of whom are experienced, fully certified American Society of Mechanical Engineers (ASME) IX and BS EN ISO 15614-1 welders.

The company also offers welded fabrications for extreme environmental conditions, and both 2D and 3D Solidworks capabilities.

When equipment is subject to low temperatures, brittle fracture may subsequently occur. Wakefield Acoustics holds welding certifications down to -40°C for mild steel and 304 stainless steel.

Quality, safety and compliance to noise control standards

Wakefield Acoustics has extensive experience of operating to exacting specifications on complex contracts. The company has a team of experienced project managers, and a high degree of knowledge of the documentation and certification requirements of high specification contracts.

Wakefield Acoustics’ enclosures are tested in accordance with BS EN ISO 11546-1: 2009, as required by BS EN ISO 15667 (acoustics) guidelines for noise control enclosures and cabins.

The company is accredited to:

- IS0 9001: 2008

- IS0 9001/14001/18001 IMS – pending 2016

- Achilles Building Confidence

- Safe Contractor

Noise control solutions

Available in mild steel, stainless-steel or fully painted, Wakefield Acoustics supplies a wide range of additional noise control products for the offshore industry.

This includes fully welded silencers (inlet, inlet filter, discharge and blow off), acoustic screens, and blankets.