W. Maass (UK) is a specialist manufacturer of pipe flanges and subsea pipeline components serving the needs of the oil and gas, petrochemical and process-related industries. Furthermore, extensive stocks of commodity pipes, fittings and flanges are available for immediate delivery and package supply requirements.

Stainless-steel, duplex, super duplex and CRA clad carbon steel forged pipe flanges

W. Maass (UK) manufactures the complete range of forged pipe flanges. Production and stockholding are concentrated in austenitic stainless-steels, duplex, super duplex and CRA clad carbon steel.

Standard products supplied include:

- Pipes – seamless, welded

- Fittings – butt weld, forged

- Flanges – all types, weld neck, blind, orifice, etc.

- Spectacle blinds / spades / spacer

Special products manufactured to order include:

- Riser flanges

- Swivel ring flanges

- Anchor flanges

- Bulkheads – pipe-in-pipe / bundle

- Manifold blocks

- Tubesheets

- Special forged block fittings

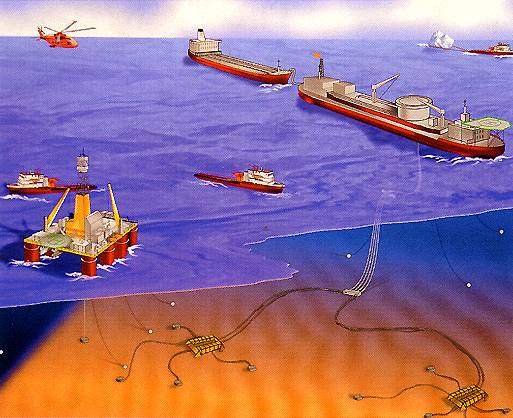

- Subsea pipeline components

Project orders are managed professionally by qualified personnel. Experience lists of successfully completed oil and gas / subsea projects can be supplied on request.

Pipes, fittings and flanges inventory

Large stocks of pipes, fittings and flanges are maintained in stainless steel, duplex, super duplex and 6 moly materials at our St. Helen’s distribution centre. The full range of ANSI pipe flanges, 150LB to 2500LB in sizes ¼in NB to 24in NB are maintained.

W. Maass (UK) stocks the following grades of materials:

- Austenitic stainless-steel, 316L, 304L, 321

- Duplex stainless-steel UNS NO. S31803

- Super duplex stainless-steel UNS No. S32750 / S32760

- 6 moly stainless-steel UNS No. S31254

- High-yield carbon steel ASTM A694 F65

Information on other grades of materials on application.

Many stock items are purchased and certified with Norsok or equivalent testing from approved suppliers.

With our undertaking to include high pressure and heavy wall components, many items are readily available which would not normally be found ex-stock. Flexible on-site facilities allow for modification by machining, saw cutting, testing and NDE.

A 24-hour emergency breakdown service is operated for hotshot requirements.

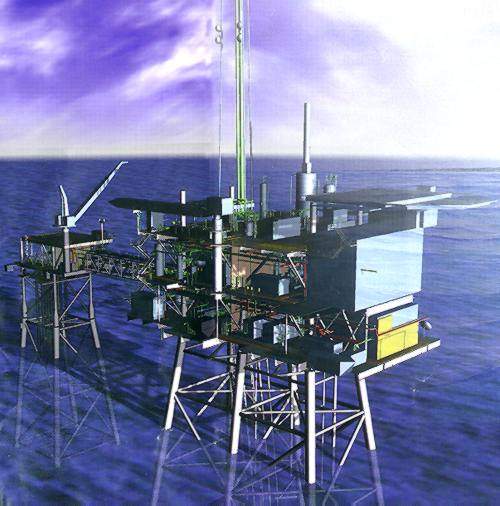

Well-equipped manufacturing facility

W. Maass (UK) operates a 4,000m² modern well-equipped machine shop utilising conventional and CNC equipment. All products are manufactured to a high specification, well within the normal tolerance and finish demanded by the oil industry standards.

Pipe flanges are manufactured according to ASME B16.5, ASME B16.36, ASME B16.47, API 6A, API 17D plus BS and DIN standards.

Extensive stocks of base materials together with a wide variety and size of flange forgings are maintained in order to manufacture special items on an urgent basis. All materials are purchased from approved mill sources and to controlled specifications. CRA lined flanges and fittings are manufactured in accordance with customer requirements.

In-house facilities include turning, drilling, milling, saw cutting, quality testing and NDT.

Accredited quality management system

W. Maass (UK) Ltd. operates a quality management system which is fully approved to BS EN ISO 9001 by Lloyds Register Quality Assurance. Original approval was appointed in 1992 and has been continually updated.

All products are manufactured and supplied in accordance with the requirements of the customer’s purchase order and associated international and contractual specifications, the control of which is ensured through the W. Maass (UK) Ltd Quality Management System.

W. Maass (UK) Ltd. is registered on the First Point Assessment System. Supplier No. 10040255.

Established in 1980 as a subsidiary to Wilhelm Maass & Co KG, a leading European forgemaster, W. Maass (UK) has continually expanded facilities in St Helen’s to become one of the UK’s market leaders in the production of flanges and pipeline products.

For more information on any of W. Maass’ products and services, please don’t hesitate to contact us using the forms on this page or the email addresses below:

lee@w-maass.co.uk – Sales Manager

fred@w-maass.co.uk – Q.A. Manager

pclare@w-mass.co.uk – Project Sales Engineer