SIRON Deluge Services is a leading supplier of fire system products and services that offers a personal approach and experienced team, along with an impressive track record of rapid delivery of multiple services across all regions worldwide.

Safety Services for Offshore Operations

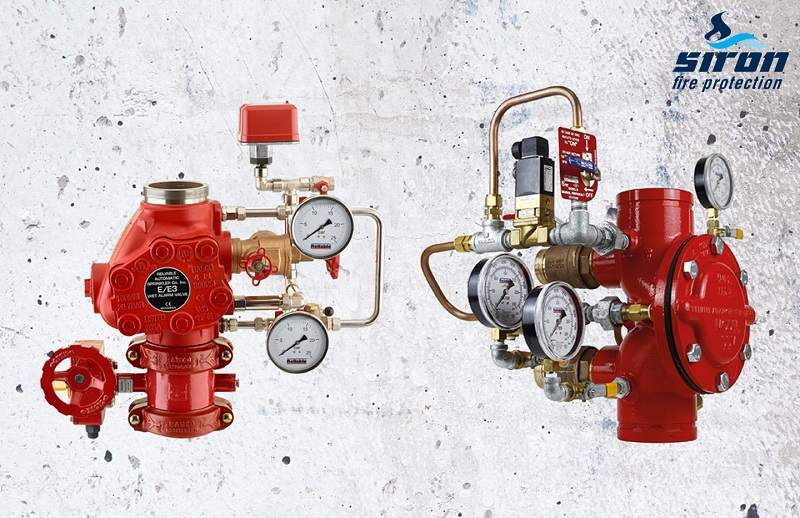

SIRON offers a full range of technical services including both wet and dry deluge testing, compressed air foam, pipe cleaning, deluge valve supply and overhaul (including Inbal and C300 Elastomeric Valves), firefighting foam supply and testing, and corrosion inhibition.

SIRON Patented Dry Deluge Test

To extend the life of the deluge system and production equipment contained within the protected areas, we test deluge systems with vapour instead of water.

By thoroughly utilising our vapour tests, the results meet the requirement standards of wet tests and prove equal or better in comparison. These results have been attested by an independent third-party accreditation institute.

SIRON Dry Deluge Testing meets standards criteria specified by:

- NFPA 25 Chapters 8, 10, 11, 13

- FM Global Datasheets 2-81, chapters 2.3.4, 2.3.5, 2.3.8, 2.3.14, tables 3 and 6

- CCV Technisch Bulletin 80

- Norsok S-001-Technical Safety, chapter 20.4.4

Wet Deluge Testing v Dry Deluge Testing:

Deluge systems are the primary fire safety system for most plants and require annual mandatory testing.

The wet testing method can lead to the growth of microbiologically influenced corrosion (MIC) and salt crystallization in flow pipes and nozzles, as well as exacerbating any existing corrosion within carbon steel systems, which can lead to blockages of piping and spray heads.

Excessive firewater discharged when using the wet testing method will overflow the sump/drain tanks, and in arctic conditions freezing firewater can be dangerous.

Overall, the use of the wet testing method can lead to the risk of unplanned business loss and plant shutdown due to water ingress.

The dry testing method is safer and less expensive. The testing can be performed without interrupting production, and there is less preparation involved than wet testing.

With the vapour testing method, leaking flow pipes are easier to spot and any residual water from former tests will be blown out of the deluge system. The process equipment is protected from seawater contact during testing, maintaining plant integrity.

The dry testing method reduces internal corrosion in flow pipes, leading to fewer solids in the system. It also prevents new organisms like shells growing in flow pipes, resulting in fewer blockages.

Compressed Air Foam (ICAF)

Compressed air foam (ICAF) is generated by the combination of compressed air, water and foam. ICAF uses four times less water and up to six times less foam concentrate compared to foam-water systems. It also offers better performance in extinguishing and burn-back resistance.

- Water supply: ICAF can eliminate or reduce the size of water supply tanks and fire pumps

- Drainage and containment: ICAF can eliminate or reduce the size of drainage and containment systems, including spill tanks and oil separators

- Disposal costs: the significant reduction in foam and water required for ICAF reduces the costs associated to clean-up and disposal of foam during discharge testing or after a fire

ICAF applications:

- IT: emergency generators and diesel storage areas

- Pharmaceutical: process areas, chemical storage, laboratories, loading and unloading gantries

- Transportation: urban transit fuelling bays, maintenance garages, aircraft hangars, ethanol transfer stations and heliports

- Power generation and distribution: power transformers, turbine generators and nuclear facilities

- Oil and gas: tank farms, oil pumping stations, refineries, offshore drilling platforms, pump rooms and lube oil skids

- Industrial: wood treating machines, solvent storage and process areas

Pipe Cleaning and Descaling:

All water-based fire protection systems should have an unrestricted water supply in case of an emergency. Most deluge systems are constructed from carbon steel piping due to its low cost. Carbon steel and sea water do not mix, leading to a number of corrosive issues over time, which affects piping and blocks nozzles.

Removing corrosion from your deluge system will extend the lifetime of the entire system. SIRON Fire Protection Services offers two means to descale piping and clear nozzles. Both mechanical and chemical descaling are cost reducing and highly effective.

Chemical cleaning is effective due to its unique composition, both iron oxide preventing and removal, as well as friendly to the environment. There is no risk of spillage into the sea due to our CEFAS certification.

Minimising disruption of production operations is always imperative in our cleaning process.