Parker Hannifin Corporation is the world’s leading diversified manufacturer of motion and control systems and technologies. Parker’s Racor Division – Village Marine Tec. (VMT) provides innovative offshore oil and gas project solutions, including innovative potable watermakers, water filtration, seawater desalination with reverse osmosis (RO) and related water purification equipment for some of the world’s most demanding applications.

Parker specializes in maritime, offshore oil and gas, land-based and disaster relief applications. We also manufacture a wide range of high-turbidity water treatment products, including drinking water filtration, ultra filtration and brackish water filtration products.

Marine hoses, power cables and mooring lines

Parker’s Energy Products Division provides innovative project solutions (marine hoses, power cables, mooring lines, high-pressure hoses, custom umbilicals, surveying, metrology and service) with customer-focused project management, for global energy recovery.

Offshore desalinators and seawater watermakers

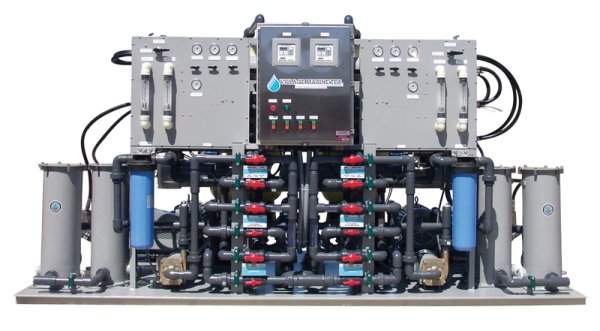

Parker Hannifin’s custom configured (CC) modular offshore oil and gas desalinators are compact and offer a lower weight to production water ratio. Our watermakers are sized from 100 GPD to over 300,000 GPD. Our watermakers are in use worldwide in applications such as drilling rigs, offshore work boats, yachts, oil platforms and many land-based applications. We have authorized sales and service locations in over 48 countries.

Parker Hannifin custom builds each watermaker at its state-of-the-art manufacturing facility in Los Angeles, California. We manufacture our own high-pressure titanium pumps, media filters, pre and after filters and RO membranes. Our environmentally friendly green technology allows us to control every aspect of our manufacturing techniques and process.

Marine-rated oily water separators

Parker Hannifin’s marine-rated oily water separators (OWS) ensure that all bilge water condensate is properly treated prior to being disposed of into our lakes and oceans. Parker Hannifin’s oily water separators are installed on many workboats throughout the world and are approved by ABS, the United States Coast Guard, and meet IMO, MEPC 107 regulations. These oily water separators utilize a three-stage system that optimizes the separation and complete removal of free and emulsified oils to less than 15 ppm.

Offshore seawater desalinators

Parker’s new offshore seawater desalinators are specifically designed and engineered for harsh offshore applications such as MODU, FSO, FPSO and drill ships. Desalinators can be configured with all necessary equipment and accessories in a single enclosed aluminum flame-coated skid frame.

Desalinators include options such as media and activated carbon pre filters, de-chlorination pretreatment by SMBS (sodium metabisulfite dosing) and ORP (oxidation reduction potential) . Second pass treatment is available for turbine wash or boiler feed water purity. Hazardous work environments include explosion-proof controls that meet and exceed NEC class Division 1 Group 2, Division 2 and IEC 60079, zone 2, group IIA, T3. We offer ultraviolet light germicidal skid packages and GRE / FRP piping for deck installations.

Parker offers the highest quality engineering, service, and manufacturing in the oil and gas industry. Bring us your current challenge; we will work with you to provide a safe and cost-effective solution. We engineer your success.