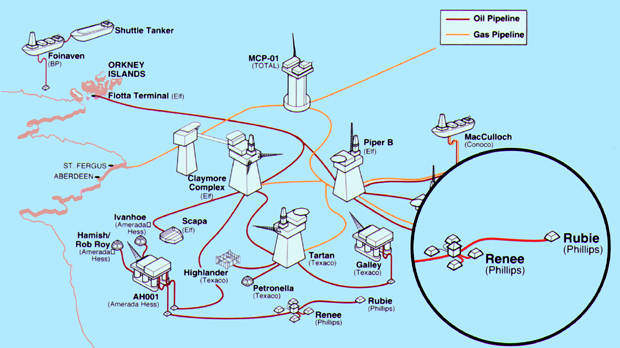

The R-Block development is located approximately 200km north-east of Aberdeen.

Renee lies in 146m of water, 21.6km from the AH001.

Rubie lies in a water depth of 148m, 5.6km away from Renee.

Geology

Renee is an Upper Jurassic reservoir, while Rubie produces from a Palaeocene reservoir.

Drilling

The first stage of the development saw the drilling of a water-injector well, followed by the re-entry of the 15/27-6 well, which was originally drilled in September 1997. This was completed as a producer.

The new production and water-injection wells were drilled by the rig JW McLean.

Stage I was concluded by the drilling of a production well on Rubie.

Depending upon the results of the Renee production, Stage II is anticipated to consist of a further production and injection well there.

Production: Renee

The Renee subsea facilities consist of a manifold and four subsea wellheads, enclosed by steel cages. The Renee manifold weighs about 100t. It was made and installed in two parts.

In July 1998, the protection structure was lowered and piled into the seabed. Afterwards, the instrumentation of the manifold was placed into it. This meant that the instrumentation was unaffected by piling forces and could be tested onshore.

The protective steel cage was designed to carry a 50t load on all the main members, together with an impact energy absorption of 26kJ from trawl or anchor impact loads. The cage measures 15.6m x 20.2m and is 5.5m-high.

The piping skid weighs 70t and the protection structure a further 48t. It is kept in place with 9t of piles.

The oil from Renee is transported to the AH-001 platform for processing via two 21.6km, 8in pipelines. At AH-001 the oil is metered and co-mingled before being passed into the Flotta system. The gas is fed into the Tartan system and gas lift is provided in a 4in pipeline from AH-001. Injection water is provided in an 8in pipeline.

Renee is controlled from AH-001 by means of electrohydraulic umbilicals.

Production: Rubie

Rubie is developed by a single subsea production well. Oil is transported to the Renee manifold in a 5.6km, 8in pipeline. At Renee, the oil is co-mingled and transported to AH-001. Gas lift is provided to Rubie via a 3in pipeline running from Renee.

Rubie is controlled from AH-001 via Renee by means of an electrohydraulic umbilical. The Rubie well has a christmas tree, with an integral steel-protection structure.

Pipeline

In total, there are nearly 100km of pipelines. Many of these have had an insulation coating (costing more than twice as much as the pipe itself) to minimise heat loss.

Pipelines passing from the AH001 to Renee, cross over two other gas pipelines, so pipe-bridges and crossing structures have also been constructed.

AH001

Originally built as the Sedco Phillips SS drilling rig, the semisubmersible AH001 was converted by Amerada Hess into a production semisubmersible. At Nigg Bay, two cross-pontoons were inserted between the existing pontoons for an increased stability and fatigue resistance.

The 12,500t semisubmersible then sailed into Tyneside, where 2,500t of equipment was replaced with 6,000t of processing equipment and structural reinforcement.

These included five Ruston Tornado turbines driving the power and compression units along with two emergency generators, each producing 1.5MW of power. It was one of the first designs to take advantage of post-Piper design in the layout of the facilities.

The AH001 has the processing capacity for 60,000 barrels of oil a day and 58.5 million cubic feet a day of gas.

It can inject 92,000 barrels of water a day and has the capability of converting 60t of seawater into drinking water. It is secured by a 12-point mooring system.