Bolting and Positioning Components

Hydraulically installed bolts designed specifically to remove uncertainty and increase asset performance.

Radial Fit Bolts

Removing uncertainty by safe and faster installation, longer product life, predictable and reduced maintenance downtime with lower overall costs.

How it Works

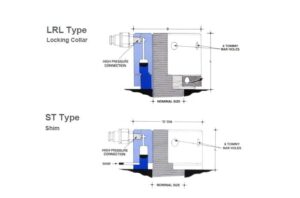

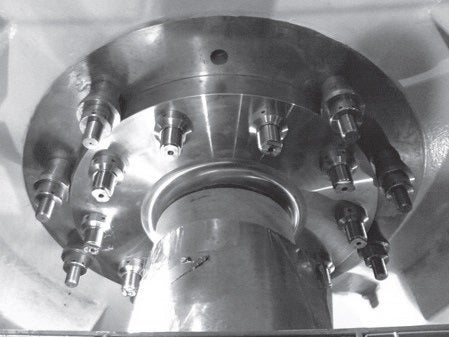

The principle of the Radial Fit Bolt features a combination of a taper bodied bolt and matching taper bored sleeve.

During installation the bolt is positioned into the coupling holes in a clearance condition, by using the hydraulic tooling provided, the sleeve expands by drawing the bolt through the sleeve to provide a true interference fit. The nuts are positioned and the bolt is hydraulically tensioned. For removal, the bolt and the sleeve are separated using either the oil injection method or the removal bridge. The sleeve reduces in diameter to its original size leaving the bolt assembly free to slide out of the coupling hole in a clearance condition.

All Radial Fit Bolts are made to order and there are two design options when choosing the correct Radial Fit.

Standard Bolt

This bolt is longer than the Compact versions allowing for the hydraulic equipment to utilise the threaded area prepared for the nuts. Generally used in slower rotating applications, such as Marine propulsion shaft Flanged Couplings.

Compact Bolt

The Compact designed bolt utilises Pilgrim’s Unique removable taper threaded Puller for installation, giving the advantage of a shorter bolt and thus improving the aerodynamics for critical high-speed applications such as a Steam or Gas Turbine flanged couplings in the Power Generation Sector.

Accessories

ClampBolt

Pilgrim’s ClampBolt range are designed with budget in mind, whether it’s used in conjunction with our premium RadialFit Bolt design from 40mm dia. Plus or unaccompanied, we deliver a high integrity and bespoke tensioned bolt system.

The ClampBolt is installed in a clearance condition and then hydraulically installed by stretching the bolt and manually tightening the nuts giving you a predetermined and optimised clamping force.

End Covers

Commonly used in Marine applications Pilgrim can provide machined steel or rubber End Covers to protect the protruding threat on a Standard Radial Fit Bolt / Clamp Bolt.

Windage Plates

To aid the improvement of a couplings aerodynamic performance and cleanliness in high-speed applications, Pilgrim have several neat designs for windage plates that

attach to the end of the hydraulically installed bolts.

Datum Plugs

Provide a simple aid in measuring the length of the hydraulic radial Fit Bolt. The Datum Plug provides an accurate and consistent reference point for your measuring system. The bolt length measurement can be taken before and after hydraulic tensioning to verify that the installation and loading has been undertaken correctly.