Jorin manufactures, services and supports visual process analyzer (ViPA) instruments for the on-line measurement of oil concentration, oil drop size distribution, total suspended solids and solid particle size distribution in oilfield water systems.

ViPA instruments are used to generate continuous process data in produced water treatment, separation and filtration systems, particularly where treated produced water is being re-injected for sweep and pressure maintenance in producing formations. The ViPA also has applications in monitoring the treatment of seawater and aquifer water for injection purposes and for monitoring of treated, produced water that is being discharged overboard.

Fixed or mobile water-treatment plant process instrument

Jorin offers the ViPA either as a permanently installed process instrument package, monitoring single or multiple sample points within a water treatment plant, or as a mobile instrument transferable between sample points. All ViPA systems can handle high temperature (120°C) and high pressure (120bar) samples and are ATEX certified for use in hazardous areas.

Both mobile and permanently installed ViPA systems can be configured for use in highly ambient temperatures and are suitable for use in desert environments.

Mobile offshore process survey instrument

The MZ3 mobile instrument is particularly suitable for offshore process survey, as its modular construction allows it to be rapidly broken down into sub-20kg packages for easy handling between sample points. The permanently installed instruments are self-maintaining and have been installed in unmanned locations. The data from a permanently installed ViPA can be used for process management and performance verification.

The mobile instruments can be deployed for process troubleshooting, establishment of fluid specifications, performance testing of new process devices or optimisation of existing plant and monitoring of chemical trials. Jorin provides contract technicians to operate the mobile instruments where required, and will collate all data and prepare reports to client specifications.

Optimisation of three-phase separators, hydro-cyclone vessels, compact flotation units and filtration plants

Previous case studies have included optimisation of three-phase separators, hydro-cyclone vessels, compact flotation units and filtration plants.

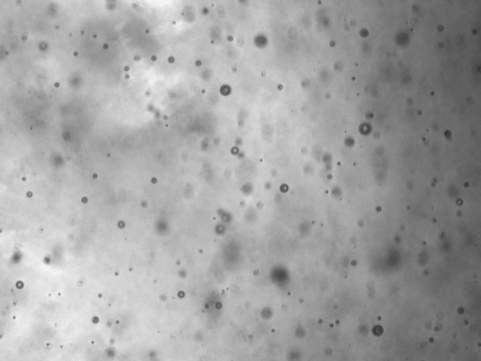

Video imaging and analysis for water-system particulate data

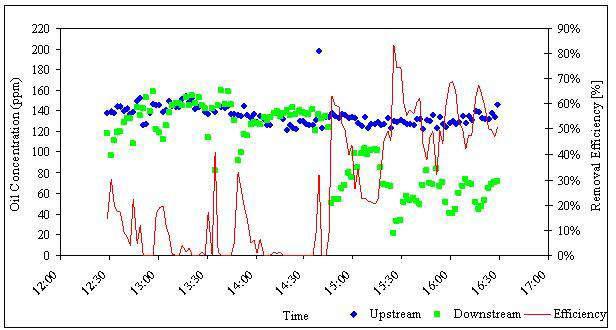

The ViPA uses continuous online video imaging with image analysis to provide size, shape and concentration data for all particulates present in oilfield water systems. Using information on particle shape, objects can be classified as oil drops, gas bubbles or solid particles.

The information can be stored in separate databases, allowing the continuous monitoring of up to eight particle populations simultaneously. Detailed investigation of shape parameters can further identify solid particles, typically as sand, process scale, biological material or agglomerated oil and solids.

The richness of this data stream means that operators do not have to rely on a single parameter such as oil concentration to characterise a produced water stream.

Complete model of oilfield water quality

This additional information on oil drop size, solid particle size and type, and the potential origin of troublesome solids, gives a more complete model of water quality and the power to resolve many process issues.