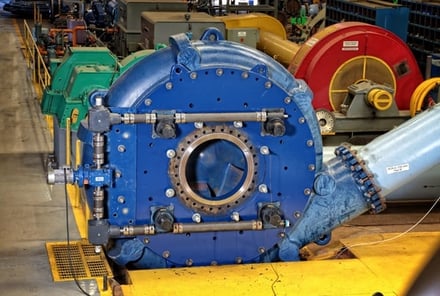

GIW Industries Inc, leader in the design, manufacture and application of heavy-duty centrifugal slurry pumps, announced the Remotely Adjusted Mechanical Suction Liner (RAMSL) product enhancement for the GIW® Minerals MDX Pump.

The RAMSL is the next phase of a continuous improvement plan between GIW and Escondida, the largest copper mine in the world. Escondida currently operates eight MDX-750 pumps in their cyclone feed lines. This revolutionary upgrade allows maintenance personnel to adjust their pump suction liners in less time and with less human power than ever before. What once took 32 work hours per week now takes a single worker just a few minutes with the simple push of a button.

Developed with safety in mind

The MDX-750 is designed to be in continuous use over five months or a total of 4,000 hours. Efficient pump operation in this aggressive wear application is only possible through precise weekly maintenance. One of the key maintenance procedures is adjusting internal clearance between the pump impeller nose gap and the suction liner. Historically, these adjustments were made using hand tools near the rotating equipment.

While these adjustments are safe, Escondida was dedicating up to four maintenance work hours per pump per week, and with eight MDX-750 pumps in operation that time was adding up. To make the process even safer and more efficient, GIW’s R&D team developed a remotely adjustable system. The RAMSL technology allows the operator to mechanically control suction liner adjustment with a control module.

GIW Senior Engineer Leo Perry said: “The two primary benefits RAMSL brings are increased safety and ease of maintenance. Both benefits stem from the ability to adjust the equipment against roughly 400,000lbs of force from a safe distance without exerting more effort than it takes to press a button on a touchscreen.”

The RAMSL user-interface serves as both the control panel for unit operation as well as an output source for critical data taken from the pump. With this new technology, Escondida is able to track real-time vibration readings and precise suction liner movements to within 0.01 of a millimeter. This allows mine operators to take a closer look at their pumps without the cost-prohibitive demands of a large crew or an unnecessary shutdown.

Industrywide benefits

GIW installed the first RAMSL prototype on Escondida’s MDX-750 pumps this spring. They are actively monitoring the programme to quantify results, and the preliminary feedback is impressive. The customer is seeing reduced maintenance time and the ability to fine-tune maintenance intervals with minimal interruption. Escondida has requested additional pumps to be outfitted with RAMSL enhancements this year.

Although RAMSL was developed with this specific customer in mind, GIW knows it’s a product that will revolutionise the industry. That’s why GIW is looking forward to bringing it to market, and continuing to enhance its capabilities for years to come.

MDX project manager Diwakar Aduri is particularly excited about RAMSL’s future.

“As technology improves, we want to make RAMSL part of the Internet of Things so it can report back to KSB and GIW to be monitored,” Mr. Aduri said. “We’ll be able to see how many millimeters a liner has been adjusted and how often, and then provide predictive maintenance requirements with recommendations.”

RAMSL is another example of GIW’s long-term commitment to customer satisfaction and industry leadership.

“This is a pretty big step for a major pump manufacturer in hydrotransport,” Mr. Aduri says. “We’re quickly realising its potential.”