Completion / Workover System Safety Bails

The safe operation of floating drilling rigs at all times is a well-known industry challenge; during completion, well testing, well intervention and workover (C/WOR) operations.

ScanTech Offshore is a leading provider of air compressors, steam generators, rig cooling equipment and qualified personnel for the worldwide well testing market sector.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

ScanTech Offshore is a leading provider of air compressors, steam generators, rig cooling equipment and qualified personnel for the worldwide well testing market sector.

ScanTech Offshore takes pride in delivering fully integrated well test support services to clients on an international scale.

We provide an impressive range of rental equipment, including air compressors, steam generators and rig cooling services, as well as designing, installing and commissioning bespoke heat-suppression safety systems.

Our remit extends to the provision of qualified and competent personnel for the operating, servicing and maintaining of all rental equipment, affording clients the highest standards of quality and safety for operations.

As a market-leader in the field of well test support, we are committed to providing enhanced value to our customers by tailoring our specialist skills and engineering capabilities to their precise requirements. ScanTech Offshore is a pioneer in designing innovative and technical solutions that meet or exceed regulatory, quality and safety standards.

ScanTech’s vision is to become the highest-quality and lowest-cost service provider of well test support worldwide.

ScanTech’s core purpose is to improve the profitability of our customers through outstanding performance in equipment service and personnel provision.

ScanTech Offshore always makes a conscious effort to reach and surpass client standards. Part of our effort to ensure we offer the highest-quality service is to stay up to date with all the latest industry regulations, standards and accreditations.

We place heavy emphasis on health and safety, quality and environmental policy, and putting those policies into practice. As part of our commitment to our clients and dedication to ensuring that our products and services are fit for their intended purposes, we are continuously promoting improvement of the quality of goods and services we provide, combined with maintaining a healthy and safe work environment.

Post-Macondo (Deepwater Horizon disaster), duty holders and operating companies alike have modernised safety cases for their installations to ensure the highest safety standards are written into operating procedures.

The distance between a ‘Safe Area’ and a Zone II classified area, in accordance with IP15, is three metres from any part of the surface process system. That recommendation is written for fixed production systems employing welded joints, not specifically for temporary well testing systems employing numerous mechanical connections.

During surface well testing, or whilst hydrocarbons are at the surface, steps should be taken to remove sources of ignition in the event of an undesirable gas or liquid release. The volume of gas in a working well test spread can be visualised as a 32ft sphere at atmospheric conditions.

Propagation of a sizeable liquid or gas release in a 25mph wind could be 36ft/s and in this time frame such an event would make it difficult to guard against, especially where engine or boiler intakes do not employ flame traps and/or isolating dampers. To those ends, it is easy to understand why the eminent operating companies and certifying bodies are insisting on using Zone II compressors and Zone II steam generators during surface well testing.

Late in 2012, the first pair of Zone II steam generators manufactured were deployed via airfreight to Tanzania. They joined existing 1,600ft²/min Zone II compressors and HeaterSentry® equipment hired by an established British operator involved in gas exploration. Similar projects using Zone II air compressors and steam generators are now ongoing worldwide, as demand continues to soar.

ScanTech Offshore’s range of equipment now includes a significant fleet of Zone II units built to meet the new DNV 2.7-2 standard, which covers the basic safety requirements from multiple internationally recognised standards, including SOLAS, MODU code and IEC electrical standards.

The DNV 2.7-2 certified air compressor has been designed and developed by ScanTech Offshore to cope with the harsh environments associated with well testing. Using the proven Caterpillar 3406 marine engine and robust 1,600cfm air-ends, the unit is both rugged and reliable. The versatility and safety features of our flagship air compressor have been further enhanced by recently achieving the latest DNV 2.7-2 certification.

Improved safety features include:

The DNV 2.7-2 certified steam generator is a 2,500kg/h containerised steam boiler, designed and developed by ScanTech Offshore to cope with the harsh environments associated with well testing. The design criteria and safety functions are built-in to make the boiler suitable for use in offshore Zone II hazardous areas.

Improved safety features include:

The company was founded in 1995 as Air Supply, primarily focused on the Norwegian well test market before successfully expanding globally. ScanTech Offshore, modified from Air Supply in 2002 to reflect the business’ growing capabilities, has been trading in the UK for more than ten years; in 2010 the company acquired RigCool to expand its product and service offering to the well test market.

ScanTech Offshore is part of James Fisher and Sons, a leading provider of specialist services to the marine, oil and gas, and other high-assurance industries worldwide, registered on the London Stock Exchange.

ScanTech Offshore products are delivered worldwide from our key locations in the UK (Aberdeen and Great Yarmouth), Brazil (Macae), Malaysia (Labuan) and Western Australia (Perth), with an additional office operating out of UAE (Dubai).

The safe operation of floating drilling rigs at all times is a well-known industry challenge; during completion, well testing, well intervention and workover (C/WOR) operations.

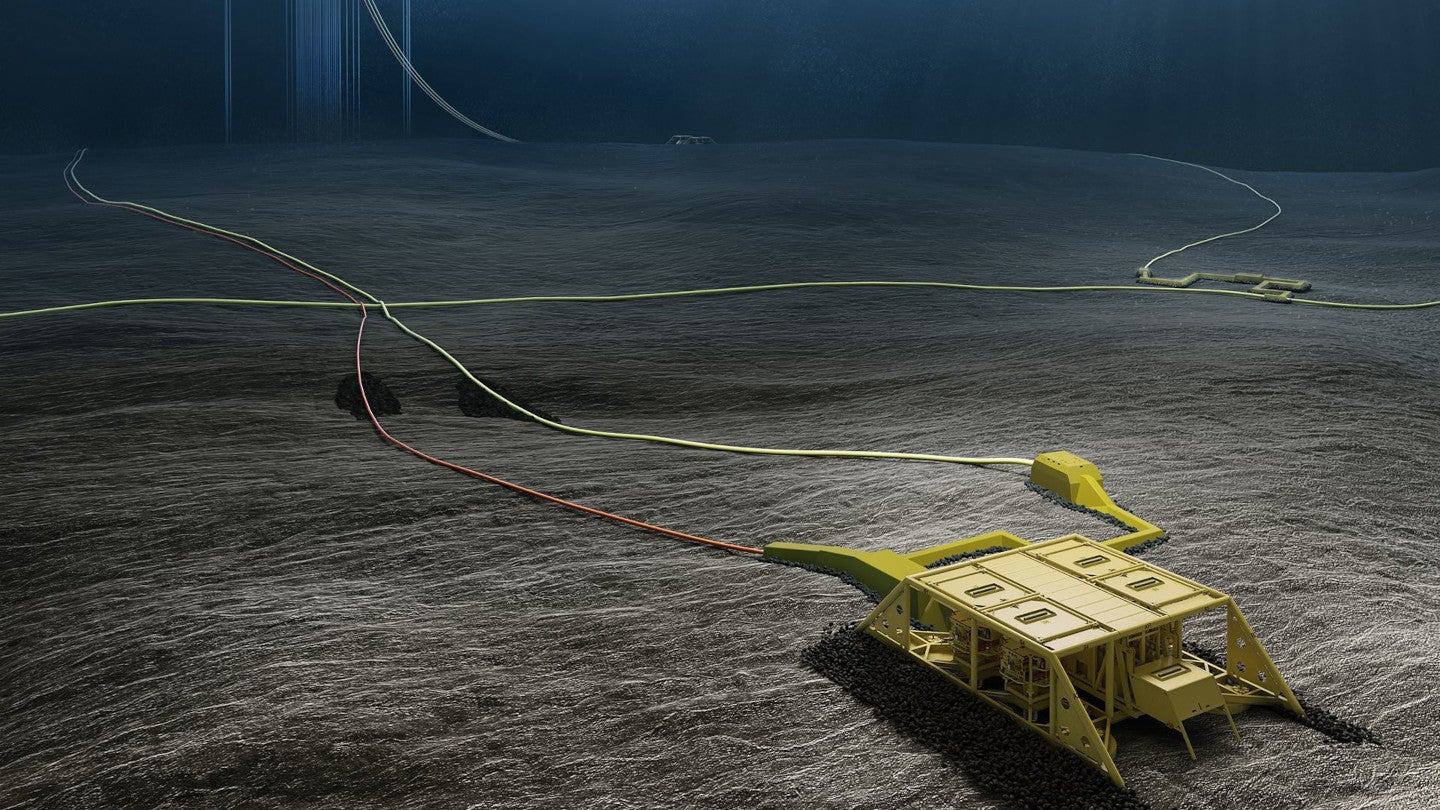

The Dvalin gas field is located in production licence 435 in the central part of the Norwegian Sea.

The Anasuria Cluster, located approximately 175km east of Aberdeen in the Central North Sea, United Kingdom, incorporates the Teal, Teal South, Guillemot A and Cook fields, all of which share the Anasuria floating production, storage and offloading (FPSO) host platform.

Gullfaks Rimfaks Valley is a Statoil-operated asset located near Rimfaks and Gullfaks South in the Tampen area in the North Sea.

The Greater Angostura field lies in block 2C, approximately 38km off the north-east coast of Trinidad, at a water depth from 120ft to 200ft.

The Bonga North West field is located in the oil mining lease (OML) 118, at a depth of more than 1,000m, approximately 120km off the Nigerian coast.

Alfa Sentral gas and condensate field lies in blocks 15/8 and 16/18a in the central North Sea, approximately 20km west of the Sleipner complex.

When seeking a supplier to provide heat exchangers, you would expect to find a deep-seated understanding of well testing processes.