Meet Dutch Filtration at ACHEMA 2024, Hall 5.0 and Booth B11

Dutch Filtration will exhibit at Achema 2024. Achema is a renowned global event that showcases the latest advancements in process industries.

Dutch Filtration specialises in the design and in-house manufacturing of filter equipment and consumables for oilfield and oil and gas applications.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Dutch Filtration BV specialises in the design and production of advanced filtration equipment and filter consumables for the upstream oil and gas sector, renewable energy field, and process industry. Our deep expertise in filtration solutions has been honed through years of hands-on experience.

Our unique approach involves the full spectrum of design, innovation, engineering, and in-house manufacturing, enabling us to maintain a high level of adaptability and responsiveness to our customers’ needs.

Dutch Filtration provides solutions that cater to a wide range of applications within the offshore industry and energy sector, including wastewater, completion fluids and water injection. Moreover, we extend our expertise to the process industry, addressing needs such as the filtration of cooling water, industrial process water and water pre-treatment.

In offshore oil and gas production, where significant water usage and wastewater generation occur, effective filtration is essential for water reuse or safe disposal. Our range of filter equipment adheres to rigorous industry standards like P.E.D., ASME, EN13445, ASTM, and ATEX.

Dutch Filtration offers industry-compliant filter equipment. Our frames are certified per DNV2.7-1, and our vessels can be constructed to PED / ASME VIII / EN13445 standards. Our team assists in equipment startup and commissioning, mindful of the stringent requirements of the offshore and process industries. We offer on-site training and expert guidance to select the ideal filtration solution for your needs. Our product support extends to post-production and onshore/offshore installation.

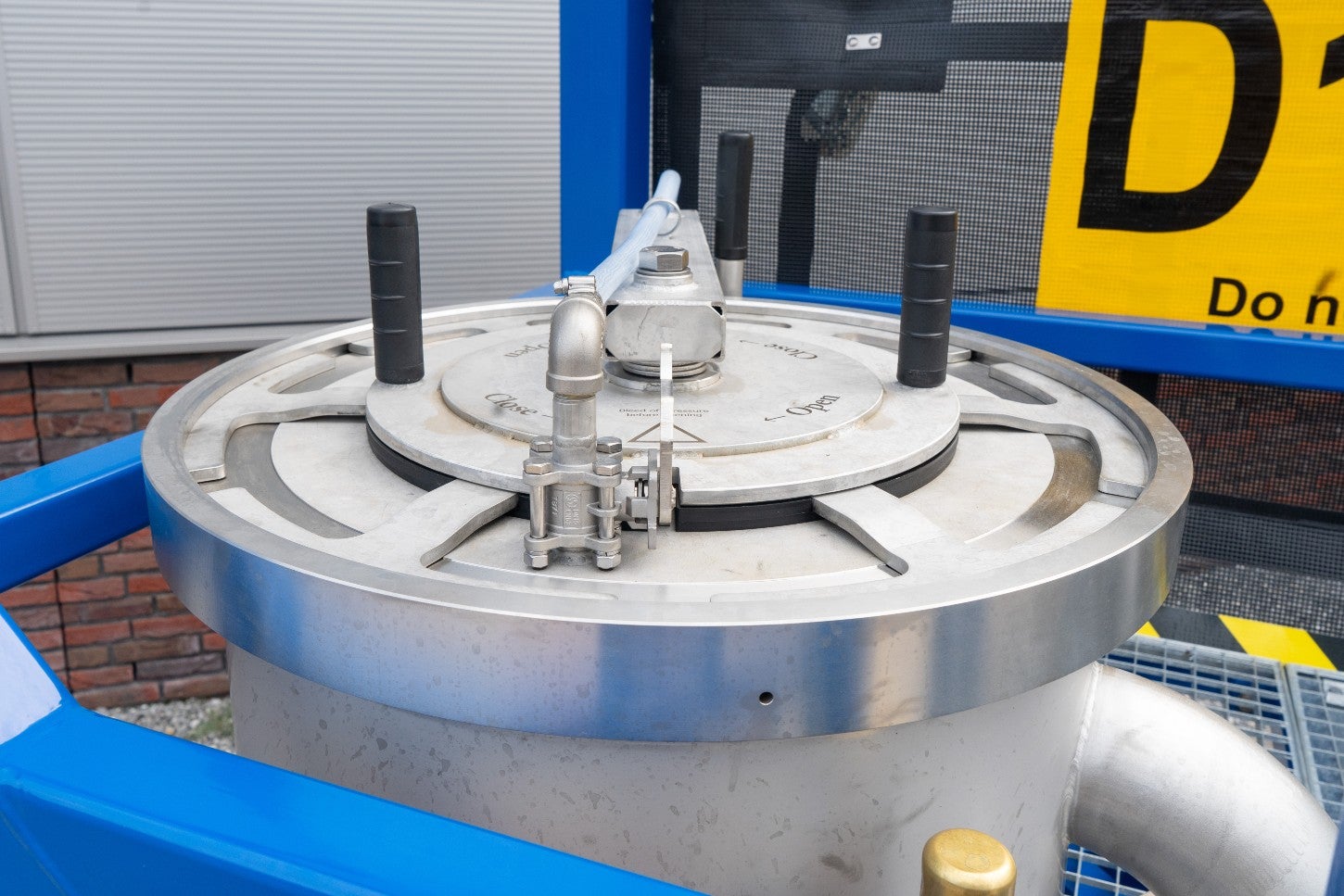

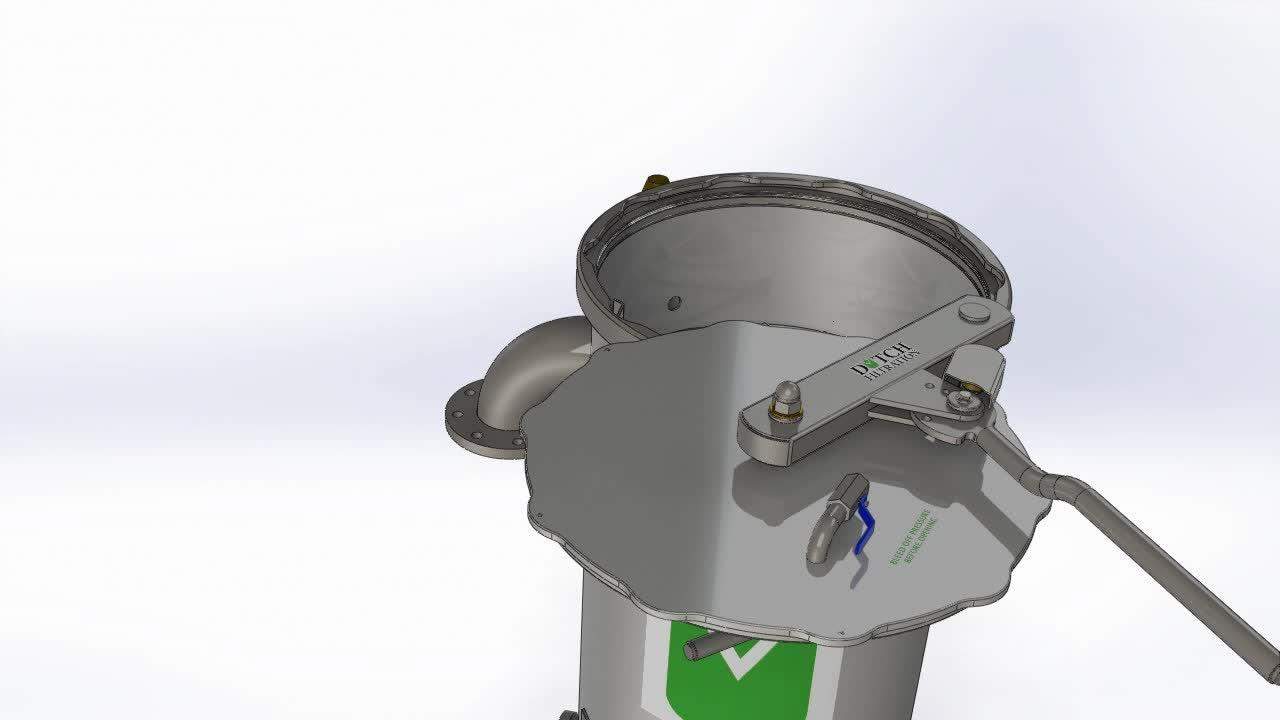

Dutch Filtration has engineered an exclusive and robust quick-opening closure system tailored for all our cartridge and bag filter units and vessels, with a special focus on serving the oil and gas sector. This pressure vessel closure system is specially designed for safe, ergonomic, quick and leak-free change out of filter cartridges.

In contrast to the conventional swing bolt closures used in cartridge filter vessels, the Rudi Quick Opening Closure offers a multitude of advantages: no need for loose nuts, no necessity for tools, a secure two-handed operation, and an incredibly fast process, typically taking just a matter of seconds. The Rudi QOC is a solution that guarantees safety, reliability, speed, simplicity, and 100% sealing integrity.

At our company, we offer an extensive range of filter elements that seamlessly integrate with filter elements from renowned brands like Cuno 3M, Pentair, Pall, Parker, Peco Facet, and more.

We have our own manufacturing facility, where we produce filters according to the highest standards in the industry.

Our products are engineered to deliver exceptional filtrate quality, unwavering product reliability, and cost-effective utilization. Our range of filter consumables includes:

For fluid filtration demands at high flow rates, we offer an extensive selection of high-flow filter cartridges:

Leveraging our profound market expertise, we stand ready to assist you in determining the consumables that best align with your specific application.

In large-scale offshore and industrial applications, the traditional multi-cartridge systems can pose challenges both in terms of size and cost. Enter high-flow filters and housing systems, offering a game-changing solution with a lot of advantages.

High-flow capability, compact design: When dealing with high flow rates or heavy contaminant loads, high-flow filter elements outshine their counterparts. For instance, a single 6.3in UltraFlow High Flow filter can handle a staggering flow rate of up to 110m3/hr (484GPM), all within a compact design. This means you need less space and can achieve exceptional performance compared to conventional pleated filters, often at a fraction of the size.

Lower disposal and maintenance costs: Conventional systems demand substantial time and manpower for cartridge replacements. In contrast, high-flow filter systems feature fewer elements, translating to shorter filter change times. Furthermore, high-flow filter elements boast a longer lifespan, resulting in fewer changeouts. This efficiency not only saves time but also significantly reduces disposal costs.

When a short-term filter system is needed, purchasing new equipment doesn’t always make sense. Dutch Filtration offers high-quality rental filter skids, designed for oilfield and general industry filtration needs. With in-house design, innovation, engineering, and manufacturing, we provide adaptable solutions tailored to your requirements.

Our range includes dual vessel filter units, vertical pressure leaf filters, pump sets, automatic self-cleaning filters, cartridges, and bag filter vessels/housings. All products are DNV2.7-1/ISO 10855/EN 12079 certified for global offshore use. Contact us for availability and pricing.

Dutch Filtration will exhibit at Achema 2024. Achema is a renowned global event that showcases the latest advancements in process industries.

Since the debut of our first Rudi Quick Opening Closure, we’ve been continuously working on improvements.

Dutch Filtration designed and manufactured a 2,400ft² Filter Press with a semi-automatic plate shifter for the safe and easy shifting of 1,500 plates.

Dutch Filtration's extensive catalogue of dual vessel cartridges and bag filter units are fully certified to PED 2014/68/EU for fluid group Cat 1, module A CE.

A video demonstrating Dutch Filtration's Rudi rapid open-closure system, for use with cartridge and bag filter housing within the oilfield industry.