Argus® Oil-in-Water Monitors

Argus® Oil in Water Monitors

ProAnalysis is a supplier of oil-in-water (OiW) monitoring solutions, both for environmental monitoring and produced water treatment process monitoring.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

ProAnalysis is a supplier of oil-in-water (OiW) monitoring solutions, both for environmental monitoring and produced water treatment process monitoring.

The unique Argus® technology introduces a new generation of oil-in-water analysers that provide accurate and reliable measurements, and are used for water discharge monitoring, as well as produced water treatment process monitoring and management.

ProAnalysis’ unique proprietary Argus technology has been developed in close cooperation with major oil and gas operators in the North Sea, as a response to the need for reliable OiW monitoring technology operating in challenging process conditions.

ProAnalysis has developed two products from the Argus technology base:

A key component of the Argus system is the online inline oil-in-water analyser, which provides a continuous stream of real-time oil-in-water data.

Argus has been thoroughly tested at several North Sea oil and gas fields, and first commercial deliveries were made in 2005 and 2006.

A main challenge associated with traditional OiW monitors is the need for bypass loops, which often are complex, expensive and require frequent maintenance. The Argus technology eliminates these problems as measurements are done through a permanent inline probe installed directly in the pipeline. The solution offers several significant advantages, including:

With its inline probe, the unique Argus technology design facilitates measurements at higher pressures and temperatures, enabling measurements throughout the water treatment process. Argus OiW monitors can be used for downstream separators, hydrocyclones, degassers and other process equipment, monitoring different stages of the process and providing the operator with unique process performance control.

The Argus technology is based on the measurement principle (laser-induced) fluorescence. A laser, uniquely developed for the sensor, emits ultraviolet light directly into the process line by fibre optics. The laser light interacts with crude oil, and fluorescence is emitted, collected, transmitted by fibre optics, spectrally and temporally filtered and finally quantified by a light sensor. The technology offers several significant advantages:

To handle challenges related to contamination, Argus is equipped with an ultrasound-based technology for the automated self-cleaning of the inline probe. Cleaning of the optical process interface is mediated through an advanced, high-power excitation of the probe’s sapphire window.

The proprietary ultrasound-based self-cleaning technology has proven highly efficient at installations facing severe challenges from scaling on process equipment, making Argus practically a maintenance-free OiW monitor in any application.

Argus Process monitors oil-in-water concentrations at high pressure and/or temperature locations in the water treatment process, paving the way for new applications for online OiW monitors.

Argus Environment monitors oil-in-water concentrations at water discharges to the environment, online and real time. Oil and gas operators are able to comply with HS&E regulations and reduce OiW levels without the need for manual water sampling and laboratory analysis.

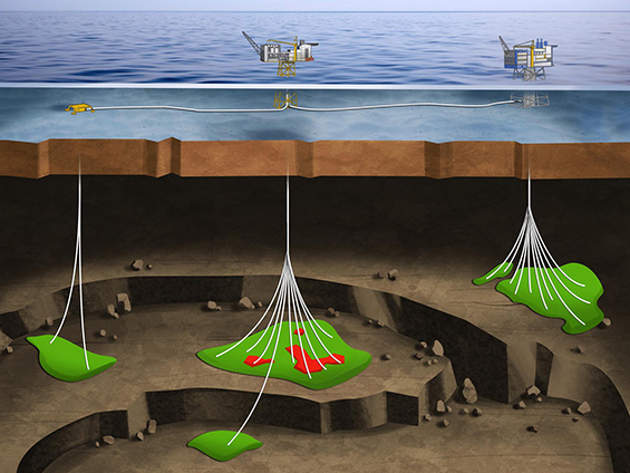

The design of Argus Multipoint enables several in-line measurement probes to be connected to the same central control unit in a multipoint oil-in-water monitoring system, resulting in significant cost reductions compared to using separate OiW monitors at each measurement point.

Up to four inline measurement probes can be connected to the ATEX-certified field enclosure, which houses the Argus control unit (laser, optics and electronics). A typical setup includes one measurement point at the inlet to the produced water treatment system, one measurement point at the outlet, and if needed, one or two measurement points at different stages of the process. Such a system provides unique control and information about the efficiency of the produced water system.

Argus® Oil in Water Monitors

The Argus® design enables several in-line measurement probes to be connected to the same central control unit through fibre-optic cable.

Johan Sverdrup accounts for roughly one-third of Norway’s total oil production.

Umm Lulu field is located in the Arabian Gulf, 30km north-west of Abu Dhabi, UAE. The offshore oil field is being developed by Abu Dhabi Marine Operating Company (Adma-Opco), a joint venture (JV) of Abu Dhabi National Oil Company (Adnoc, 60%), BP (14.67%), Total (13.33%) and Japan Oil Development Company (Jodco, 12%).

The Offshore Cape Three Points (OCTP) Integrated Oil and Gas Project includes the combined development of the Sankofa Main, Sankofa East, Gye Nyame, Sankofa East Cenomanian and Sankofa East Campanian fields.

The Cygnus gas field is situated within UK Continental Shelf blocks 44/12a and 44/11a in 23m of water.

Ivar Aasen Field (formerly Draupne Field) is located in the northern part of the North Sea, west of the Johan Sverdrup Field.

The Valhall field was discovered in 1975 and came online in 1982. It is operated by BP, which holds a 35.95% interest while the remaining 64.05% interest is held by Hess Norge.

Statfjord field, the largest oilfield in the Norwegian Continental Shelf (NCS), lies in blocks 33/9 and 33/12 of production licence 037 in the NWC, and block 211/25 of licences 104 and 293 in the UK North Sea.

The Oyong oilfield is situated 8km off the coast of Madura Island in the East Java region of Indonesia. Located at a wa

The Peregrino field is located in the Campos Basin area, 85km offshore Brazil. The field is owned and operated by Statoi

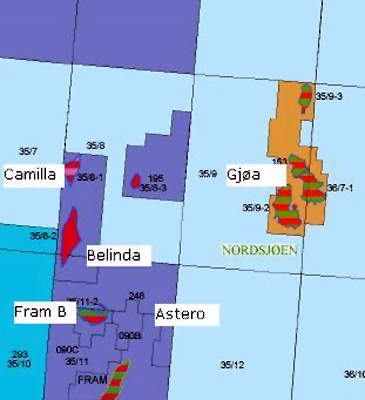

StatoilHydro's Gjøa field lies in blocks 35 / 9 and 36 / 7 of the North Sea. The field was proven in 1989 and its

Norway-based technology organisation Pro Analysis AS is pleased to announce the hiring of three new technical engineers in response to an increase in activity and a number of new contracts.

New projects on Ensco 71 and Energy Endeavour will create work for up to 180 employees at Semco Maritime and for number of sub suppliers. The long-term goal is 12 rig visits in Esbjerg Harbour in 2012. Semco Maritime ends the year of 2009 with two new rig upgrades in the harbour of Esb

Tranter, a world leader in heat transfer equipment, has acquired the German company HES Heat Exchanger Systems. With this acquisition, Tranter strengthens its product offering, especially the welded product portfolio. HES manufactures spiral heat exchangers mainly for applications with

Semco Maritime has signed a contract with the internationally acclaimed pump manufacturer Milton Roy. The deal will make it possible to integrate Milton Roy products into systems produced by Semco Maritime including chemical injection systems for oil production. "The real benefits of th

Semco Maritime has been awarded an important role in the construction of the world's first circular, floating drilling platform, currently being built in China by Sevan Marine ASA, Norway. Semco Maritime has been a partner on this technically challenging project, and is responsible for

16th December 2003 - Semco Maritime Engineering & Contracting in Esbjerg, Denmark, has entered into a contract with a large Egyptian rig operating company for upgrade of the drilling rig Kamose. Semco Maritime is to carry out a major rebuild and upgrade of the electrical generator and distrib

In the fall and early winter months of 2002 Semco Maritime has once again proven its position as the leading supplier of Line Of Sight systems in the North Sea area. Several substantial orders comprising design, supply and installation of LOS systems have been awarded to Semco Maritime from a long r