Worldwide, companies are increasingly focusing on efficient use of available water and the reuse of wastewater. With limited fresh water supplies, rising costs and tightening legislation concerning discharge, companies are looking for ways to guarantee a high-quality upstream while preventing one-time use downstream by recycling more water back into their production processes. This development can be seen in a lot of water-tight areas such as the Middle East, China, India, Southeast Asia, but also in Western countries too.

As producers of a wide range of membranes, from microfiltration to ultrafiltration and nanofiltration, Pentair X-Flow has developed a range of oil and gas-specific solutions and water treatment applications. A global player in water, Pentair aims to provide cost-effective membrane water treatment solutions that increase a customer’s return on investment and reduce their water and environmental footprint.

The recycling of wastewater is becoming increasingly important for businesses in order to continue growth and stay profitable. Tightening legislation, water scarcity, investor concerns and pressure on operational costs are some of the underlying drivers to look at new and better treatment opportunities. But whatever the key driver is, the ultimate binding factor for all industries is the need for an environmentally responsible system that provides control over the water quality on the front end and efficient wastewater treatment at the back end at an affordable price.

Water treatment for the upstream oil industry

The upstream oil industry is a significant water consumer, both water needed in the process and the water that comes as by-product. High water quality goes hand in hand with proper oil production and the oil and gas industry should aim for a balanced water approach. X-Flow membranes are capable of handling seawater, surface water, process water, produced water and boiler feed water. They can also be used for more specific solutions such as silica removal.

Seawater and surface water treatment

Seawater quality can be upgraded using X-Flow UF membranes dedicated for desalination. Oil reservoirs with a high souring and barium / strontium sulphate scaling potential will benefit from NF sulphate removal membranes protected by UF membranes. Sulphate removal reduces/eliminates hydrogen sulphide production, reducing the metal fatigue of process equipment and increasing health and safety. The complete range of X-Flow membranes is also particularly suited for non-saline applications.

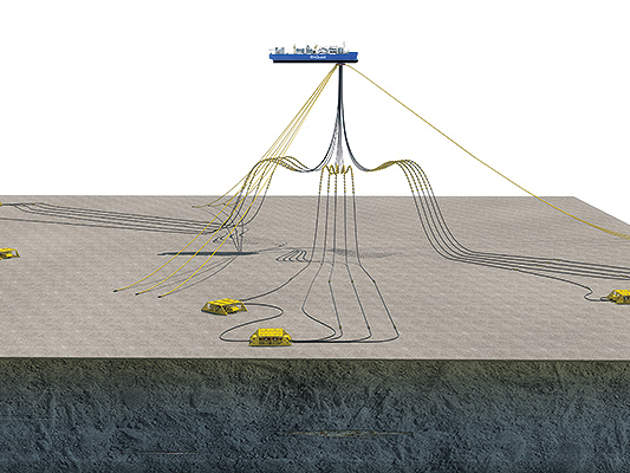

Water flooding / water injection treatment

Seawater and/or surface water are typically used for water injection / flooding and reservoir pressure maintenance. Depending on the application, all of these water types require treatment to remove unwanted impurities, such as sulphates, inorganic suspended solids like silica, organic suspended solids and salts.

X-Flow membranes are available for all treated water quality requirements, offering the most economical solution for delivering filtered and clean injection water for tight reservoirs.

Steam-assisted gravity drainage treatment

When ultra-pure water is required for steam-assisted gravity drainage (SAGD) applications, the silica content in the water becomes an issue. With tight X-Flow UF membranes, silica is removed and the boiler feed water’s scaling potential is reduced. Less scaling results in lower heating costs and reduced maintenance / downtime of the boiler plant.

Low saline produced water re-injection

The X-Flow wastewater membrane range, Crossflow UF membranes, can be applied to protect downstream NF membranes, resulting in a process where produced water can be re-used for enhanced oil recovery (EOR). Reducing the oil and/or salt content increases the wettability of the reservoir rock, allowing for easier oil displacement towards the production well.

Water treatment for the downstream oil industry (refineries)

Disposal of wastewater streams from a refinery have a significant impact on costs and environmental impact. With the X-Flow range of wastewater treatment solutions (Crossflow, AirliftTM MBR), many waste streams can be turned into valuable assets. Additionally, via concentration, a reduction can be achieved of up to five times the disposable costs. The newly developed HFW1000 Nano membranes allow colour and total organic carbon (TOC) removal.

Freshwater generation

RO membranes used for desalination are suitably protected by UF membranes (Seaguard, Seaflex and Aqualine) for the generation of freshwater.

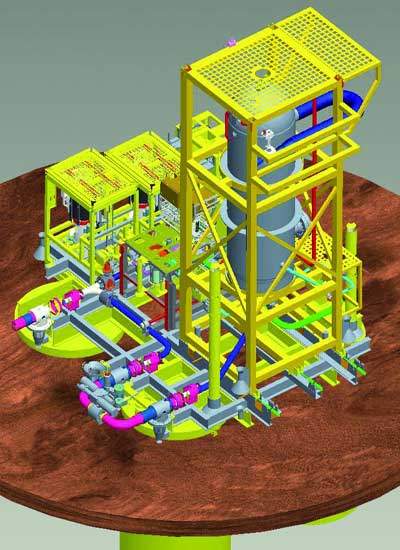

Smaller-footprint membranes requiring less equipment

X-Flow oil and gas UF membranes have a high tolerance to variations in intake water quality, only requiring small coarse upstream filters to protect them against the ingress of large particles. Direct inline piping to NF and/or RO membranes is possible as the UF membranes do not need a downstream atmospheric break tank or guard filters.

Multimedia filters (MMF), that require chemicals to enhance water quality, cannot deliver the same quality generated by UF. They are also heavier, have a larger footprint and higher OPEX.

Advantages of water treatment membranes

X-Flow membranes are designed to operate at high flux rates, resulting in reduced installation footprint requirements. This is especially of interest for offshore applications. All X-Flow membranes are made according to hollow fibre or tubular principles with an inside to outside flow pattern, meaning cost effective and reliable cleaning of the membranes and a high recovery rate.