Thermtech is the technology owner of the patented thermal desorption modulator (TMD®) and thermomechanical cuttings cleaner (TCC®) processes used to treat the contaminated solids, like the oily waste produced during drilling, production and refinery activities.

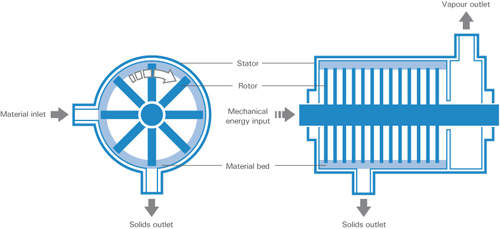

The TMD and the TCC convert kinetic energy to thermal energy by creating friction in the waste.

Direct thermal desorption units for waste treatment

Across the world, numerous companies require the use of the direct thermal desorption units for the treatment of their waste. The TMD and TCC processes are used for the treatment of countless different contaminated solids.

The most important property of the TMD and TCC is their ability to recover every component of the waste, with the same qualities of the original components.

At the end of the treatment, the oil can be reused and the clean solids (down to 0.01% TOC) can be used in different applications, land filled or discharged to sea.

Compact thermomechanical cuttings cleaners

The design of a compact, mobile TCC unit is among Thermtech recent developments. With this solution, instead of transporting the waste to the location of the treatment unit, the mobile unit is transported to the waste.

Aside from the obvious logistical savings that such a mobile unit can bring, its use can also make the whole process much safer by reducing the waste movements, which in itself are dangerous, unhealthy and environmentally negative.

This very compact unit can be installed on trailers, supply boats and offshore rigs, and still offers the same technological advantages, capacities and parameters that have made the Thermtech direct thermal desorption units so successful.

As of December 2014, more than 55 units, designed and built by Thermtech and its license holders, can be found in operation worldwide, located on land, platforms and rigs both onshore and offshore.

Using the same reliable, efficient and proven technology, Thermtech is presently bringing to the market new applications designed to handle different types of industrial waste.