Intertec provides environmental protection and temperature-regulation solutions for sensitive field equipment.

The company’s range includes field enclosures, cabinets and shelters, and thousands of accessories including heating / cooling components.

Standard solutions are available for all common field equipment and environmental protection needs, including frost / condensation protection, temperature regulation, explosion-proof areas, impact-resistance and UV protection in adverse locations.

Glass-reinforced polyester shelters in offshore environments

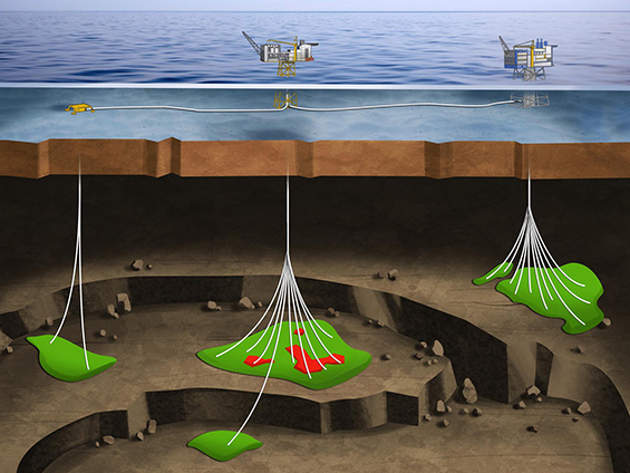

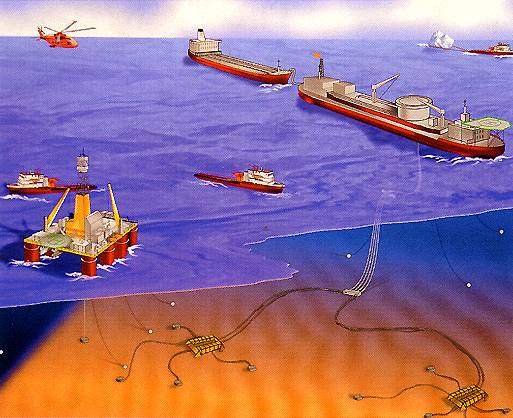

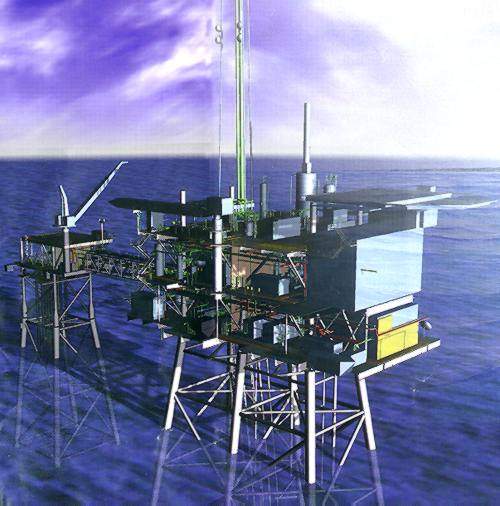

Offshore installations represent one of the most extreme environments for protective field enclosures due to the risk of corrosion, and the need for lightness and long lifecycles with minimal maintenance. In addition, hazardous area applications require additional characteristics, including fire-resistance and blast-proof protection.

Traditional metal enclosures can be susceptible to the accelerated corrosion mechanisms found on offshore platforms.

By contrast, glass-reinforced polyester (GRP) does not excessively rust or degrade, providing maintenance-free lifecycles of at least 30 years.

Intertec has created enclosures and cabinets that have survived up to 40 years in petrochemical environments using corrosive chemicals such as sulphuric acid.

The company’s composite-GRP, which combines GRP layers with embedded high-performance insulation, provides many opportunities to optimise protection against particular hazards.

Turnkey design and configuration solutions for offshore plants

Intertec’s turnkey SAFE LINK design and configuration service provides a complete, pre-fabricated ‘hook-up’ for field-based plant instrumentation. The service covers the complete concept-to-installation process, including engineering design, assembly and on-site delivery. Intertec will also configure protection to deal with a wide range of climates.

Other solutions include sample conditioning systems for analysers and ‘hot boxes’ to prevent media condensation and crystallisation at instrumentation points.

Intertec offers seven styles of instrumentation-sized enclosures with various features to suit different operational requirements. A wide range of larger cabinets and shelters are also available.

This turnkey approach typically improves the performance and reduces lifecycle costs because of the designs used and the use of modular building-block components. TProtection systems are also designed using layout principles that reduce the variability of instrument installation and provide a site standard, which simplifies maintenance, training and spares holdings to reduce total cost of ownership.

Special GRP enclosures and shelters

Intertec produces enclosures and shelters using high-grade GRP, which is known for its thermal insulation and resistance to corrosion. What is less well-known is GRP’s outstanding performance in extreme conditions, as it remains durable and stable at temperatures down to -100°C. Its thermal insulation and fire-retardant properties can also be configured to provide effective protection against fire.

For the last 50 years, Intertec has incorporated GRP into its solutions with extreme protection requirements, which includes long-duration fire-resistance, Arctic-grade climates, non-toxic fumes during a fire, passive cooling, energy-efficiency and protection against strong winds.

Solving protection challenges in onshore and offshore environments

Intertec is experienced in resolving a wide range of issues that occur on offshore and onshore platforms, including:

- Corrosion: resistant to corrosive effects of sulphur from oil or gas, chlorine from offshore locations

- Long lifecycle: durability of GRP for extra-long lifecycles is field-proven

- Offshore wind, cyclones and typhoons: GRP ‘sandwich’ composite structures can be designed with appropriate stability

- Blast-proofing: structure is strengthened easily to absorb pressure waves – with minimal additional weight

- Fireproofing: ‘sandwich’ structures with mineral wool for hydrocarbon fire-resistance, with internal temperature maintenance below 60ºC

- Separating hazardous and non-hazardous areas: fire-resistance, gas tightness and explosion-proofing

- Improving explosion-proof enclosure reliability: traditional metal EX-d enclosures can be prone to corrosion. Alternative EX-e and EX-p enclosures are easily made in GRP

- Wireless networking: GRP (and foam insulation) do not damp electromagnetic signals

- Lightness: GRP is around 25% of the weight of metal

About Intertec

Intertec has been providing turnkey solutions since 1965 and has designed and shipped more than a million enclosures that protect equipment operating in the most demanding operating conditions worldwide.

The company’s personnel has broad experience in designing and configuring environmental protection.