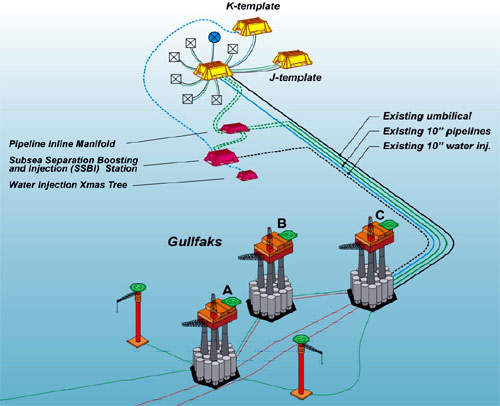

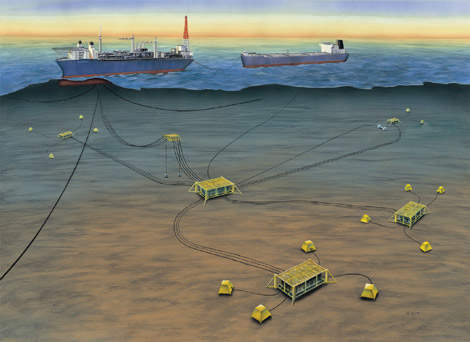

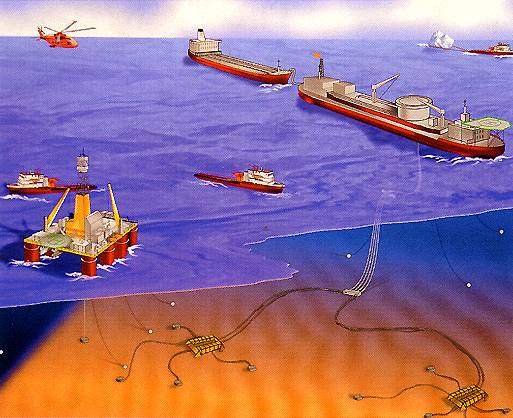

Welaptega Marine is a world leader in underwater inspection technologies, specialising in risk management for offshore installations. Welaptega’s innovative technologies allow operators to evaluate the integrity of their underwater assets and make informed engineering decisions regarding operational safety.

Technology for rapid response to underwater damage and the inspection of moorings, risers and pipelines

Welaptega specialises in both rapid response to underwater damage events, and in integrity verification through regular inspection of moorings, risers, and pipelines.

Technology includes:

- High-definition video (HD3DV). The offshore industry’s highest visual acuity

- 3D modelling (3DM). Geometrically accurate modelling of asset condition

- Chain measurement system (CMS ). Class required chain measurement metrics

- Rope measurement system (RMS). Rope surface condition and diameter measurement

- Mechanical caliper. Ad-hoc ROV based measurement capability

- Welaptega’s underwater and onshore measuring technologies allow operators to not only determine the condition of their assets but to implement a best practice asset integrity management

- Welaptega’s survey capabilities and technologies meet international industry standards and are certified by Lloyds’ Register and Det Norske Veritas.

Underwater HD3DV and 3DM technologies provide state-of-the-art visualisation of underwater assets on offshore instillations

HD3D video for underwater images

Welaptega’s HD 3DV camera system is deployed by ROV to capture high-definition 3D video footage of subsea components. Video can be viewed in 3D in real-time during inspections and ROV operations. Video can also be reviewed ‘on the beach’ following an offshore operation. High quality 3D allows operators to identify damage such as gouges and pitting.

Stereoscopic video provides ROV operators with greater spatial perception for real-time manipulator work, allowing tasks to be completed more quickly and with greater precision.

Welaptega’s HD3DV system is rated for subsea deployment to 3000m.

3DM for high-resolution, geometrically accurate models

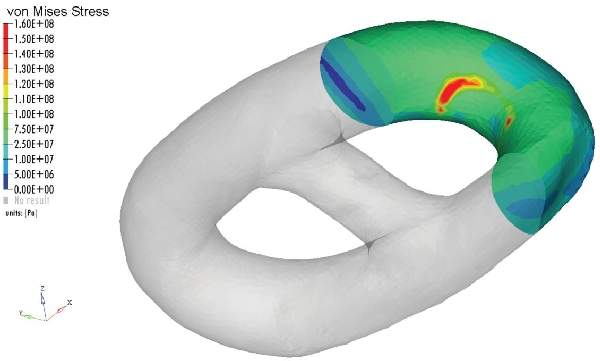

3DModelling uses advanced photogrammetric techniques to generate geometrically accurate 3D models of components from 2D digital still images. Corresponding pixels are identified between overlapping photos, and geometry is calculated through a series of iterations based on the pixel’s relative positions. 3D models are scaled with respect to the known offset between cameras or an object of known dimensions placed on the component.

Resulting 3D models represent component geometry with accuracy typically within 1mm, and can be measured to quantify critical dimensions such as ovality, alignment between planar surfaces, cross-sectional areas, and gouge depths, widths, and heights. 3D models can also be exported in formats compatible with finite element method software packages for stress / strain analysis.

If a repair is required, the 3D model can be exported to industry-standard computer-aided design (CAD) packages so that a custom design can be created to fit the damaged geometry.

Resulting models can also be 3D printed to produce prototypes, mock-ups for subsea workscope operations planning, or for display purposes.

Chain management system for measurement of intergrip diameters of subsea morning chains

Welaptega’s chain measurement system (CMS) is an ROV-deployed optical calliper that measures the link intergrip diameters of in-service subsea mooring chain.

Welaptega provides operators with measurements that indicate how much material loss has occurred due to deterioration, such as corrosion or wear. Results are compared to industry standards and classification society inspection rules and industry guidelines.

Advantages of using Welaptega’s CMS for mooring inspection include:

- Chains remain in-service during inspection; no shutdown in production or deck recovery required

- Visual inspections of individual links are performed both during data capture and when data is processed

- A comparison to previous inspection results is provided in Welaptega’s reports to identify trends in corrosion or wear patterns, allowing more accurate replacement budgeting

Rope measurement system for monitoring in-service condition of materials

Welaptega’s rope measurement system (RMS) is a unique method for monitoring in-service condition of fibre or wire rope moorings.

It is deployed by work class ROV to survey the in-service condition of fibre and wire rope moorings. Comprising a built-in cleaning system and a hydraulic sled equipped with video cameras, the RMS is towed along a rope to remove marine growth and capture video from four directions.

The video data is then processed to detect changes in the cross-sectional geometry over the length included in the survey. These measurements indicate potential rope deterioration, which could lead to mooring line failure.