FOAMGLAS® Insulation Systems for Industrial Applications

Sustainable design is becoming more important, and the demand for sustainable products with low environmental impact continues to grow.

For more than 60 years, Pittsburgh Corning has produced and developed innovative FOAMGLAS® insulation systems.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

For more than 60 years, Pittsburgh Corning has produced and developed innovative FOAMGLAS® insulation systems. From cryogenic cold to superheated steam temperatures, FOAMGLAS cellular glass is the insulation with the most to offer when dealing with the demands of an end user’s ‘mission critical’ facilities.

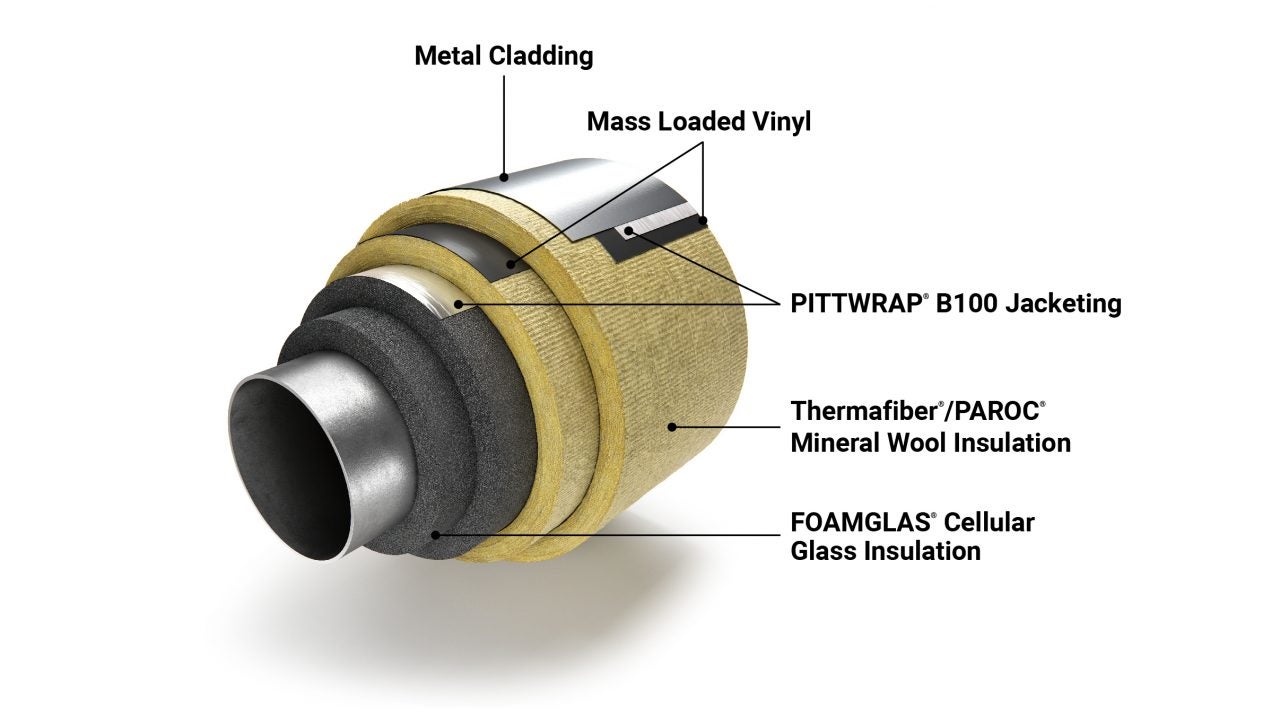

FOAMGLAS cellular glass insulation gives unrivalled long-term insulating performance. 100% closed-cell FOAMGLAS is the oil and gas industry’s first choice to prevent corrosion under insulation (CUI), and to give industry-leading fire protection and safety. Prefabricated, factory-coated systems include FOAMGLAS Terostat and the FOAMGLAS XP jet-fire protection system.

With our own fabricating facilities and five manufacturing facilities in Europe and North America, the FOAMGLAS insulation team is globally aligned, with the ability to supply large industrial projects from multiple sources if necessary.

The FOAMGLAS insulation team of quality sales and engineering personnel work side by side with facility owners, designers and insulation contractors to create the best high-performance insulation solutions with the lowest lifecycle cost to the end user.

FOAMGLAS is a uniquely 100% closed-cell insulation. It is impermeable to both liquid water and water vapour. The best protection against CUI is a fully closed-cell structure, which means that process pipework and equipment is kept dry and protected from the causes of CUI.

FOAMGLAS Terostat PCFR combines the established FOAMGLAS insulation with a factory-applied flexible polymer coating. The FOAMGLAS Terostat system can be applied far more rapidly than other traditional insulation / coating and cladding systems, and avoids the requirement for heavy pails of mastic to be handled on-site. The system can be easily installed by abseilers.

FOAMGLAS Terostat also increases the level of protection against CUI by providing a continuous joint-free weather coating with a high level of flexibility and integrity against abuse on-site.

As FOAMGLAS insulation is made from pure glass, it cannot burn and will not produce smoke in fire. It brings the highest levels of fire protection for personnel and process plants to the onshore and offshore industry. FOAMGLAS is the only cellular insulation material able to obtain the highest fire safety classification, EuroClass A1, under the new European fire-safety standards, which are progressively replacing older national standards.

Simply installing FOAMGLAS insulation around a pipe or vessel already adds significant fire protection. Several hours of hydrocarbon pool fire protection can be achieved with FOAMGLAS and a thin stainless-steel cladding. For jet fire several simple systems are available, including FOAMGLAS with Unifrax / Thermal Ceramics blankets and stainless-steel cladding or site-applied intumescent coatings, e.g. Chartek and Pittchar.

FOAMGLAS XP adds a factory-applied intumescent epoxy coating to FOAMGLAS insulation and enhances the level of fire protection. Long-duration jet-fire protection can be achieved with this composite system. Installation is rapid, even by abseilers, since the system is supplied in pre-coated shells, which are simply joint-sealed, attached to the pipework, then banded. This system is fully inspectable and can be easily removed / immediately reinstated.

All FOAMGLAS insulation systems can be factory prefabricated into straight sections, elbows / bends, dome ends, cones, valve and flange boxes, all designed to enable site work to proceed quickly and to maximise installed quality. These prefabricated items can be factory coated with a variety of weather and vapour barrier coatings.

Pittsburgh Corning specialises in producing innovative FOAMGLAS insulation systems designed to both minimise installation time as well as to protect companies and their people worldwide™.

We have released a video of the factory production and site application of the FOAMGLAS Terostat PCFR pre-coated insulation system. Pre-application of the flexible outer Terostat covering to FOAMGLAS cellular glass insulation increases site installation speed and allows an effective barrier to be created against water ingress and CUI. To view the video, click on the link below our contact details (second URL).

Sustainable design is becoming more important, and the demand for sustainable products with low environmental impact continues to grow.

Insulation performance and system integrity is directly related to the dimensional stability of the insulating material.

The Laminaria and Corallina fields, located in the Timor Sea 550km north-west of Darwin, ceased production in 2019.

Girassol is one of the four major production hubs of Block 17, which is operated by TotalEnergies.

The life of the White Rose field is expected to be extended through the development of the West White Rose satellite field.

Hibernia is located in the Jeanne d’Arc Basin, 315km east of St John’s, Newfoundland and Labrador, Canada, in a water depth of 80m.

The Eastern Trough Area Project (Etap) is an integrated development of seven different reservoirs located 240km east of Aberdeen, UK, in the Central North Sea.

Bonga is the first deepwater project for the Shell Nigeria Exploration and Production Company (SNEPCO) and for Nigeria.

The Cygnus gas field is situated within UK Continental Shelf blocks 44/12a and 44/11a in 23m of water.

The Prirazlomnoye oilfield is located south of Novaya Zemla in northern Russia on the Pechora sea shelf, at a distance o

The Gudrun oil and gas field lies in production licence 025 of the North Sea at a water depth of 361ft.

The Yme field is located in the Egersund Basin, 100km off the coast of Norway. It lies at a water depth of 93m in blocks 9 / 2 and 9 / 5 in the south-eastern region of the North Sea.

N.V. Nederlandse Gasunie (short form: Gasunie) is a Dutch natural gas infrastructure and transportation company operating in the Netherlands and Germany.

Some years ago, when three LNG storage tanks were built at an LNG terminal in the North of France, FOAMGLAS® insulation was used as the material to insulate the tank bases.

Borealis AG is a leading provider of innovative solutions in the fields of polyolefins, base chemicals and fertilisers.

Koole Terminals is a leading independent storage company in North-West Europe headquartered in Zaandam, Netherlands.

Skangas AS, owned by Finnish company Gasum and Norwegian Lyse, builds and operates medium-sized, low-carbon emission energy plants.

As a 'workhorse' insulating material for industrial applications, cellular glass insulation performs across a broad range of temperatures, provides load-bearing capabilities and resists liquid or vapour moisture intrusion.

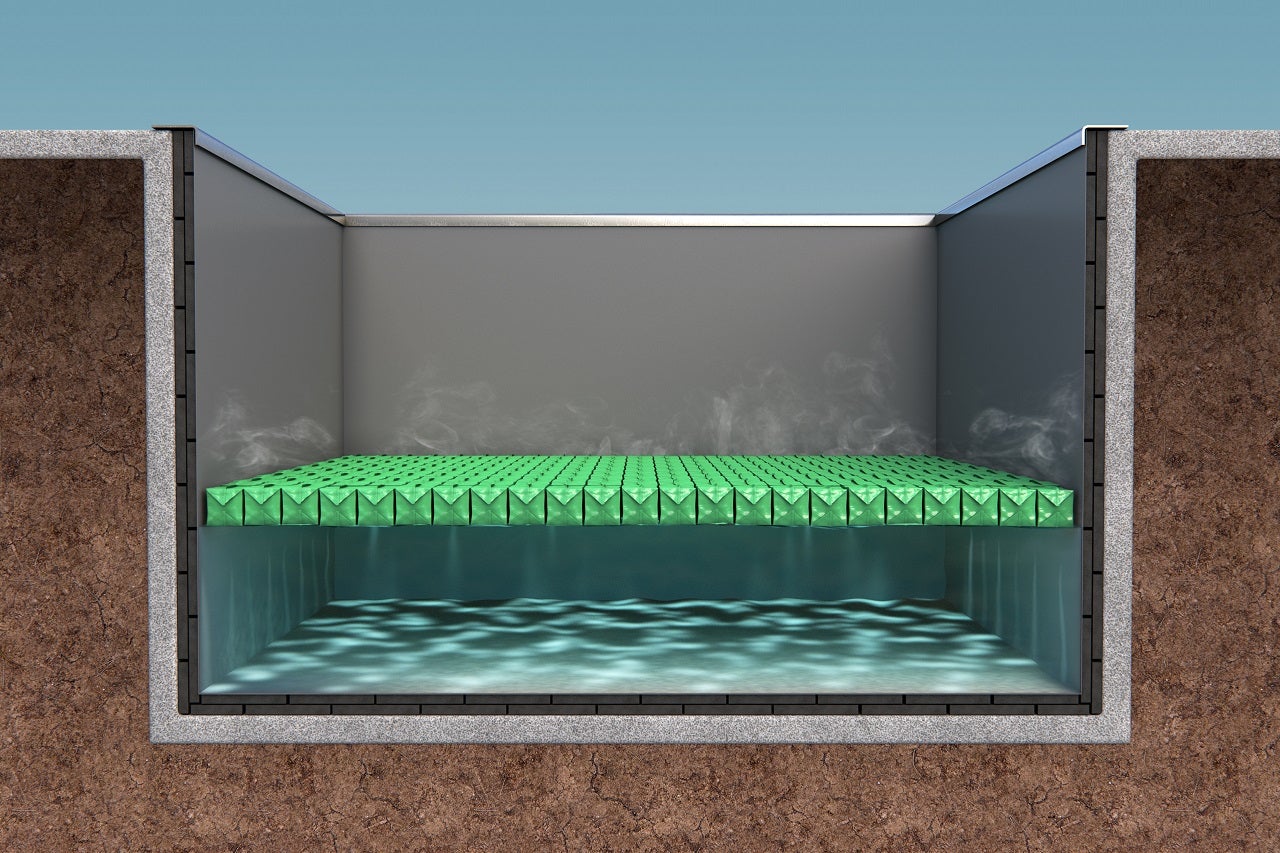

The combination of FOAMGLAS® PFS™ and FOAMGLAS® Cryo Spill™ systems can deliver improved and cost-effective passive fire suppression.

Owens Corning has multiple acoustic insulation systems available that can help you with the mitigation of excessive noise attenuation from processing piping and equipment.

Fires can result when combustible liquids, such as oils and heat transfer fluids, are absorbed by insulation materials (also called “wicking”). Even certain insulation materials that are noncombustible can absorb liquids that are combustible and, consequently, can contribute to the spreading of a fire.

FOAMGLAS® has a brand new website.

Corrosion causes serious monetary loss in all industrialised countries, particularly in industries that take place at sea. Estimates for the scale of the problem indicate that corrosion can cost as much as 4% of the gross national product of a country.

Owens Corning FOAMGLAS® insulation is pleased to announce that we will be exhibiting our innovative FOAMGLAS® cellular glass solutions again at this year’s Offshore Europe exhibition in Aberdeen, Scotland

Global insulation specialist Pittsburgh Corning has announced that the company is set to present its innovative exhibiting FOAMGLAS® cellular glass products at the ONS 2018 exhibition, which will take place from 27-30 September in Stavanger, Norway.

Pittsburgh Corning is pleased to announce that the company will be exhibiting its innovative FOAMGLAS® cellular glass solutions at this year's Offshore Europe exhibition in Aberdeen, Scotland.

The general consensus within the offshore sector is that corrosion resistance is an important safety consideration.

Fluxys LNG has awarded a deal to a consortium comprising DF Oil & Gas and Felguera IHI to carry out extension works on the Zeebrugge LNG terminal off the coast of Belgium.

Pittsburgh Corning Europe is pleased to announce it will be exhibiting at this year's StocExpo exhibition, which is set to take place from 28-30 March at The Ahoy in Rotterdam, The Netherlands.

Pittsburgh Corning Europe NV has become the first insulation manufacturing company to become a member of the Institute of Corrosion (ICorr).

Pittsburgh Corning is delighted to announce that we will be exhibiting FOAMGLAS® cellular glass at the ONS exhibition in Stavanger, Norway, which has been one of the world's leading meeting places for the global energy industry, for more than 40 years.

TOTAL's Shetland Gas Plant 'Laggan-Tormore' takes a further step near completion as the final stages of Terostat system tie-in's, by Pittsburgh Corning FOAMGLAS® insulation, are being installed.

Koole Terminals is a leading independent storage company in North-West Europe headquartered in Zaandam, Netherlands. The company operates eight tank storage terminals and an own fleet of 12 barges and three coasters.

Pittsburgh Corning Europe is pleased to announce that while our competitors are raising the price of their products, we are simply raising the bar associated with quality.

One of BP's North Sea platforms is the ETAP platform. The focus on the BP ETAP platform will be on a safe start up as another successful TAR (turnaround) comes to completion. Safety is always the key focus with BP as their 'Golden Rules' highlight for anyone who has ever worked on a BP project.

Pittsburgh Corning delivers more than 10,000m of FOAMGLAS® insulation for the insulation of piping and equipment on the topside module of the Edvard Grieg platform.

Pittsburgh Corning is pleased to announce that Kevin Bauld has been appointed industrial sales engineer for the UK and Ireland FOAMGLAS® industrial insulation markets.

Italy is one of the largest markets for the BASF Group worldwide and the Pontecchio Marconi site in Bologna is considered to be the 'flagship' of the Italian BASF sites.

Pittsburgh Corning's FOAMGLAS® Terostat insulation has again been chosen for the East Anglian gas terminals at Bacton, Norfolk.

Pittsburgh Corning's FOAMGLAS® insulation has again been specified by the UK-based, global, high-performance polymer-solutions provider Victrex Manufacturing.

Maersk Oil is an international oil and gas company with operational production of approximately 700,000 barrels of oil per day from fields in the Danish Sea, North Sea and offshore Qatar and Kazakhstan. The Gryphon A FPSO (floating production, storage and offloading vessel) operates 280 km (175 miles) north-east of Aberdeen.

Pittsburgh Corning celebrated the opening of its new multi-purpose 375m2 training centre at Tessenderlo, Belgium, by inviting our European FOAMGLAS® insulation specialists to try for themselves the extensive range of pipework rigs and vessels.

Gabriel Technologie, located in Ghlin-Baudour, Belgium, is part of the KNAUF group and was the first manufacturer of expanded polystyrene (EPS) in Belgium. With a team of 60 employees the company produces 60,000t of EPS annually, which makes them the largest polystyrene manufacturer in the Belgian market.

Pittsburgh Corning is pleased to announce that effective August 2012, the FOAMGLAS® insulation product line will carry the CE Mark.

Pittsburgh Corning is delighted to announce that we will be exhibiting FOAMGLAS® cellular glass at the ONS exhibition in Stavanger, which for more than 40 years has been one of the world's leading meeting places for the global energy industry.

The island of Guernsey is partly dependent on heavy fuel oil for its power generation. The oil has to be imported by ship and taken 0.5km by pipe along the docks and local roads to the power station.

In parallel to the continued exploration and development of oil and gas reserves, major oil companies are investing in alternative energy technologies. The recent Fukushima nuclear reactor catastrophe in Japan and its lasting consequences have triggered a review and even a total recons

Pittsburgh Corning FOAMGLAS cellular glass insulation systems will be on show at Aberdeen’s Offshore Europe exhibition from 6-8 September 2011. Innovative solutions to corrosion under insulation will be on display as well as time-saving fire protection systems pre-applied to FOAMGLAS.

Venice is famous for its fine glass, examples of which have survived for nearly a thousand years. Pittsburgh Corning also has a long history of expertise in manufacturing high-quality glass for its FOAMGLAS® cellular glass insulation. FOAMGLAS cellular glass insulation has been broug

Thermal-fluid pipework is common in the oil and gas and petrochemical industries and is a high-temperature application with the inherent danger of wicking fires. Fibrous insulation materials such as mineral fibre and solid insulation materials including calcium silicate have been shown to wick oi

Over 5,000m² of FOAMGLAS® has been installed under the Rubis storage tanks in Rotterdam. Rubis Terminal is a company specialising in bulk-storage and blending in the petrochemical and energy sectors. Its Rotterdam terminal receives, stores and turns around large quantities of