For more than 60 years, Pittsburgh Corning has produced and developed innovative FOAMGLAS® insulation systems. From cryogenic cold to superheated steam temperatures, FOAMGLAS cellular glass is the insulation with the most to offer when dealing with the demands of an end user’s ‘mission critical’ facilities.

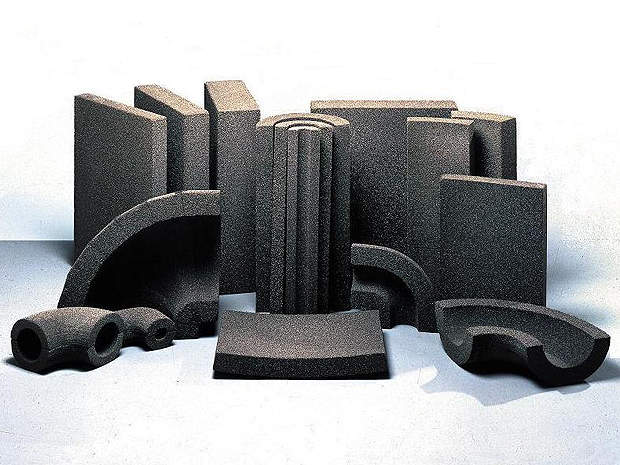

Cellular glass insulation

FOAMGLAS cellular glass insulation gives unrivalled long-term insulating performance. 100% closed-cell FOAMGLAS is the oil and gas industry’s first choice to prevent corrosion under insulation (CUI), and to give industry-leading fire protection and safety. Prefabricated, factory-coated systems include FOAMGLAS Terostat and the FOAMGLAS XP jet-fire protection system.

With our own fabricating facilities and five manufacturing facilities in Europe and North America, the FOAMGLAS insulation team is globally aligned, with the ability to supply large industrial projects from multiple sources if necessary.

The FOAMGLAS insulation team of quality sales and engineering personnel work side by side with facility owners, designers and insulation contractors to create the best high-performance insulation solutions with the lowest lifecycle cost to the end user.

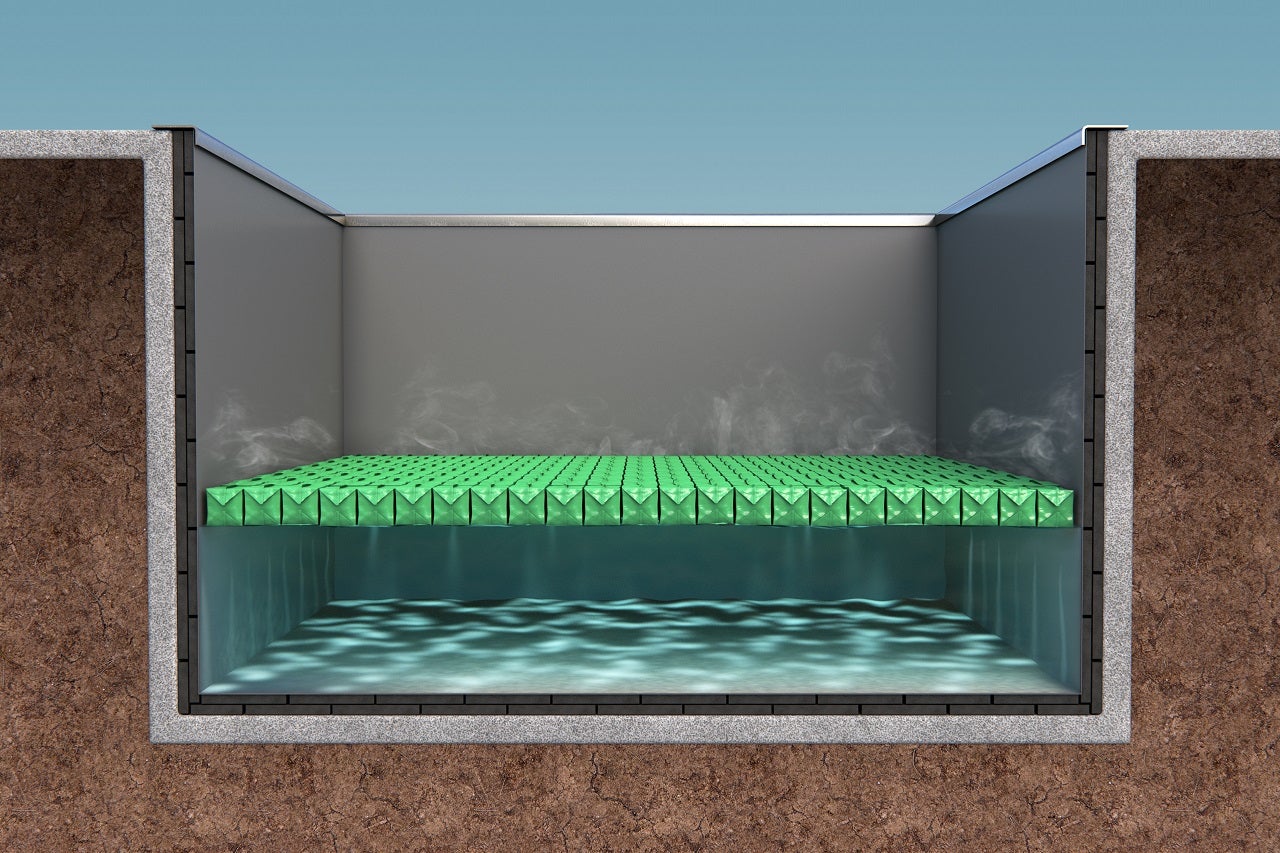

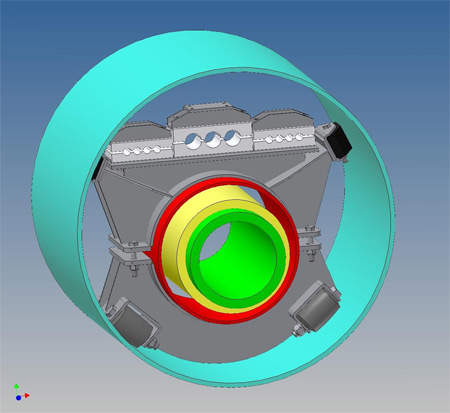

Impermeable closed-cell insulation

FOAMGLAS is a uniquely 100% closed-cell insulation. It is impermeable to both liquid water and water vapour. The best protection against CUI is a fully closed-cell structure, which means that process pipework and equipment is kept dry and protected from the causes of CUI.

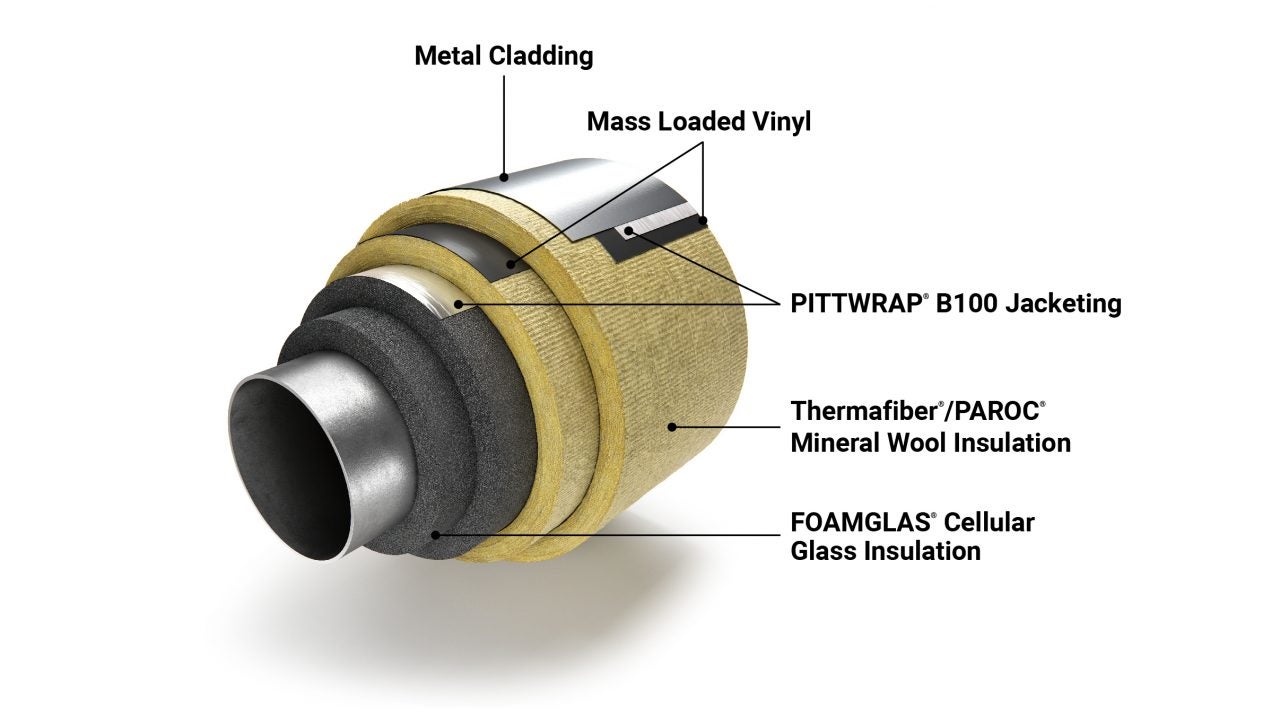

Factory pre-coated insulation system

FOAMGLAS Terostat PCFR combines the established FOAMGLAS insulation with a factory-applied flexible polymer coating. The FOAMGLAS Terostat system can be applied far more rapidly than other traditional insulation / coating and cladding systems, and avoids the requirement for heavy pails of mastic to be handled on-site. The system can be easily installed by abseilers.

FOAMGLAS Terostat also increases the level of protection against CUI by providing a continuous joint-free weather coating with a high level of flexibility and integrity against abuse on-site.

Fire-safe closed-cell insulation

As FOAMGLAS insulation is made from pure glass, it cannot burn and will not produce smoke in fire. It brings the highest levels of fire protection for personnel and process plants to the onshore and offshore industry. FOAMGLAS is the only cellular insulation material able to obtain the highest fire safety classification, EuroClass A1, under the new European fire-safety standards, which are progressively replacing older national standards.

Simplified fire protection insulation system

Simply installing FOAMGLAS insulation around a pipe or vessel already adds significant fire protection. Several hours of hydrocarbon pool fire protection can be achieved with FOAMGLAS and a thin stainless-steel cladding. For jet fire several simple systems are available, including FOAMGLAS with Unifrax / Thermal Ceramics blankets and stainless-steel cladding or site-applied intumescent coatings, e.g. Chartek and Pittchar.

Rapidly installed jet-fire protection insulation system

FOAMGLAS XP adds a factory-applied intumescent epoxy coating to FOAMGLAS insulation and enhances the level of fire protection. Long-duration jet-fire protection can be achieved with this composite system. Installation is rapid, even by abseilers, since the system is supplied in pre-coated shells, which are simply joint-sealed, attached to the pipework, then banded. This system is fully inspectable and can be easily removed / immediately reinstated.

Prefabricated cellular glass insulation systems for quicker installation

All FOAMGLAS insulation systems can be factory prefabricated into straight sections, elbows / bends, dome ends, cones, valve and flange boxes, all designed to enable site work to proceed quickly and to maximise installed quality. These prefabricated items can be factory coated with a variety of weather and vapour barrier coatings.

Safe, reliable and effective FOAMGLAS insulation systems

Pittsburgh Corning specialises in producing innovative FOAMGLAS insulation systems designed to both minimise installation time as well as to protect companies and their people worldwide™.

We have released a video of the factory production and site application of the FOAMGLAS Terostat PCFR pre-coated insulation system. Pre-application of the flexible outer Terostat covering to FOAMGLAS cellular glass insulation increases site installation speed and allows an effective barrier to be created against water ingress and CUI. To view the video, click on the link below our contact details (second URL).