Parker Twin Filter supplies complete skid-mounted systems and a wide range of consumables for fluid filtration applications.

Wastewater treatment technology

Converted wastewater can either be re-used or safely returned to sea, though disposing it can be difficult and expensive.

Parker Twin Filter has developed TwinZapp, a new field-tested technology that treats chemically emulsified water. The mobility of the system makes it suitable for specific workover projects (foam jobs), and platforms and production sites with most types of troublesome production water.

Completion fluids filtration units

Clean completion fluids are essential to maximise the productivity of the producing reservoir. Dirt particles have major effects on the permeability of the reservoir, improving the oil production and prolonging the service life of the well.

Clean completion fluids can only be obtained by using the appropriate filtration equipment and consumables. The most effective way to filter oilfield brines is diatomaceous earth (DE) filtration.

Parker Twin Filter’s vertical pressure leaf filter unit and filter press, in combination with a dual vessel cartridge filter, provide the ideal solution.

Frac fluids filtration processes

A well-stimulation technique, hydraulic fracturing is where rock is broken up by a liquid. This involves the high-pressure injection of ‘fracking fluid’ into a wellbore to create cracks in the deep-rock formations where brine, petroleum and natural gas will flow more freely.

When the hydraulic pressure is removed from the well, small particles of hydraulic fracturing proppants such as sand or aluminium oxide hold the fractures open.

Water that flows back from the fracturing process, also known as flow back water, is a combination of fracking fluid and formation water. To reuse this to frac additional wells, it should be free of chemicals and rock debris.

Parker Twin Filter has a complete delivery program to filter the water before and after the fracking process.

Well control

Well control is needed during the construction of an oil and gas well and subsequent operation.

Well control protects downstream equipment from uncontrolled hydrocarbon releases of during oil and gas operations.

Parker Twin Filter provides a well head sand filter that is designed to remove hydrocarbons, sand and other solid particles from well sewage.

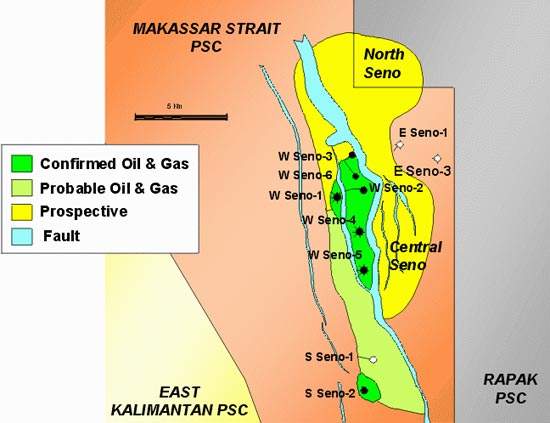

Produced water treatment

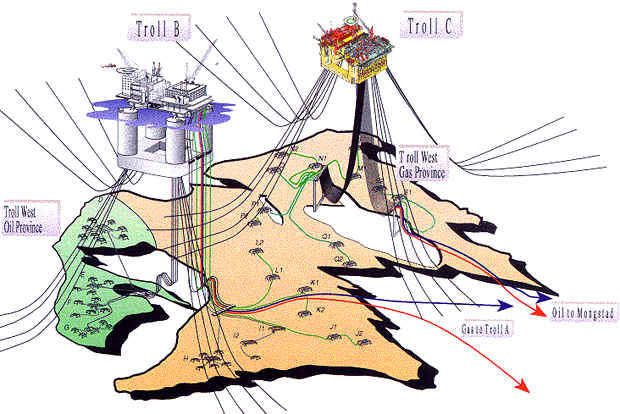

Produced hydrocarbons are brought to the surface as a fluid mixture, which depends on whether crude oil or natural gas is being created.

Fluid mixtures generally comprises either liquid or gaseous hydrocarbons, salts, metals, radon nuclides and/or production chemicals. Most produced water is injected underground, either for maintaining field pressure or disposal.

Water production at conventional oil and gas wells typically increases over time. Treated produced water has the potential to be a valuable product rather than a waste.

Parker Twin Filter offers different packages depending on the client’s application to excellently treat produced water.

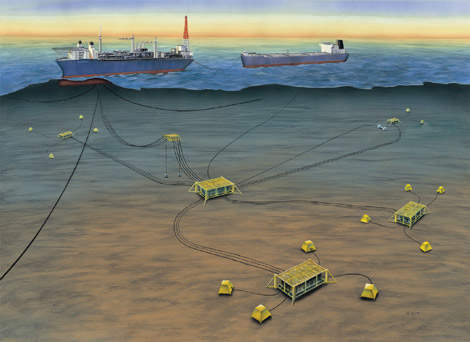

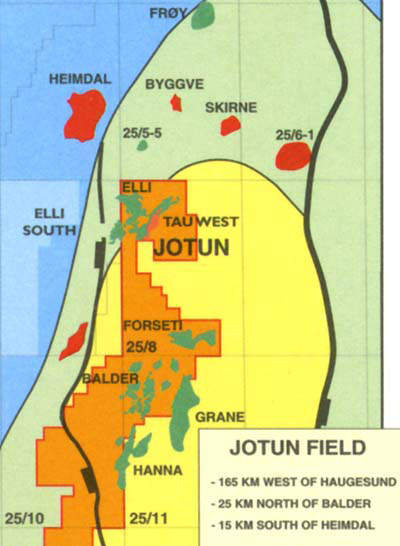

Water injection to optimise oil production

Water injection is a method used it the oil industry where water is injected into the existing reservoir to increase pressure and maximise the oil production.

To prevent damage to the reservoir and the injection equipment, the injected water needs to be free of solids.

In many situations, the most convenient fluids for injection are seawater or produced water from the well. Once at the surface, the used water must be cleaned again before reinjection (or discharge).

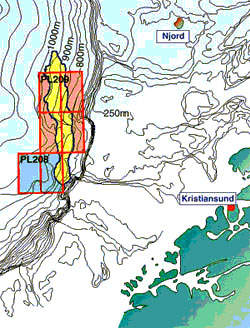

Pipeline flushing

Routine filtration and high-flow flushing key preventive maintenance measures for all rotational equipment, new and used systems. The damaging effects of particulate contamination can cause premature component wear and failure.

One method of ensuring optimal system cleanliness is periodic flushing. Turbulent flow can be achieved by circulating a flushing fluid at a very high flow rate, which dislodges particles that would otherwise stick to the walls during laminar flow.

These particles are subsequently removed from the piping as the fluid flows through a series of high-efficiency filter elements.

Parker has state-of-the-art, high-flow filtration equipment that will do the job with minimal downtime

Rental filtration equipment and services

A full range of equipment is available for rental, including TwinZapp systems (emulsified water breaker), vertical pressure leaf units, filter presses and dual vessel cartridge units.

Parker has a worldwide network of more than 50 customer service centres, guaranteeing immediate customer service and a local representative in most countries.